Manufacturing method and application of fly-ash-based aircraft tail flame infrared suppression material

An infrared suppression and fly ash technology, applied in the field of materials, can solve the problems of single evaluation index, slow development, and less research on particle arrangement of granular materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

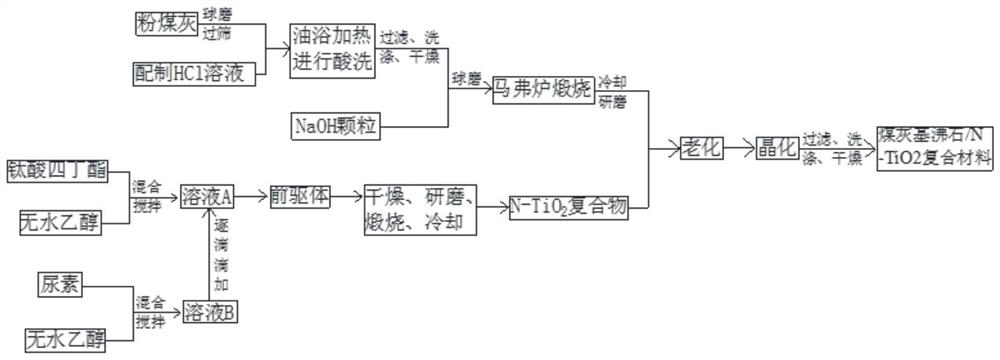

[0064] A new material for infrared radiation suppression of aircraft plume—fly ash-based zeolite / N-TiO 2 The preparation method of composite material, comprises the following steps:

[0065] 1) Mix tetrabutyl titanate and absolute ethanol at a volume ratio of 1:1.2~1.5, stir at a rate of 300r / min, stir for 20~50min, record it as solution A, mix 4.5~5.5g of urea with 90 ~120mL of absolute ethanol was mixed to obtain solution B, which was added dropwise into solution A, and decomposed by microwave under 300W for 15~30min to prepare a mixture gel, that is, to obtain a precursor.

[0066] 2) Dry the mixture gel obtained in step 1) at 80-90° C. for 12-15 hours, grind it, and set it aside.

[0067] 3) Calcinate the product obtained in step 2) in a muffle furnace at 400-500°C for 2-3 hours, and obtain N-TiO after cooling 2 composite material.

[0068] 4) Mill the fly ash with a ball mill for 5-10 minutes, and sieve through 300 mesh.

[0069] 5) Prepare an HCl solution with a mass...

Embodiment 1

[0080] Example 1 Coal ash-based zeolite / N-TiO 2 Preparation of composite materials

[0081] 1) Mix tetrabutyl titanate and absolute ethanol at a volume ratio of 1:1.2, stir for 30 minutes, and record it as solution A, mix 5 g of urea with 125 mL of absolute ethanol to obtain solution B, and add solution B dropwise In solution A, the microwave was decomposed under the condition of 300W for 30min to prepare the precursor.

[0082] 2) Dry the precursor obtained in step 1) at 90°C for 12 hours, grind it, and set it aside.

[0083] 3) Calcinate the product obtained in step 2) in a muffle furnace at 450°C for 2.5h, and obtain N-TiO after cooling 2 composite material.

[0084] 4) Fly ash is ball-milled with a ball mill for 5 minutes, and sieved to 300 mesh.

[0085] 5) Prepare an HCl solution with a mass fraction of 20%, mix the fly ash and the HCl solution after sieving 300 meshes in step 4) in a ratio of 1:10 in g:mL, and place on a constant temperature magnetic stirrer with S...

Embodiment 2

[0090] Example 2 Coal ash-based zeolite / N-TiO 2 Application of Composite Materials

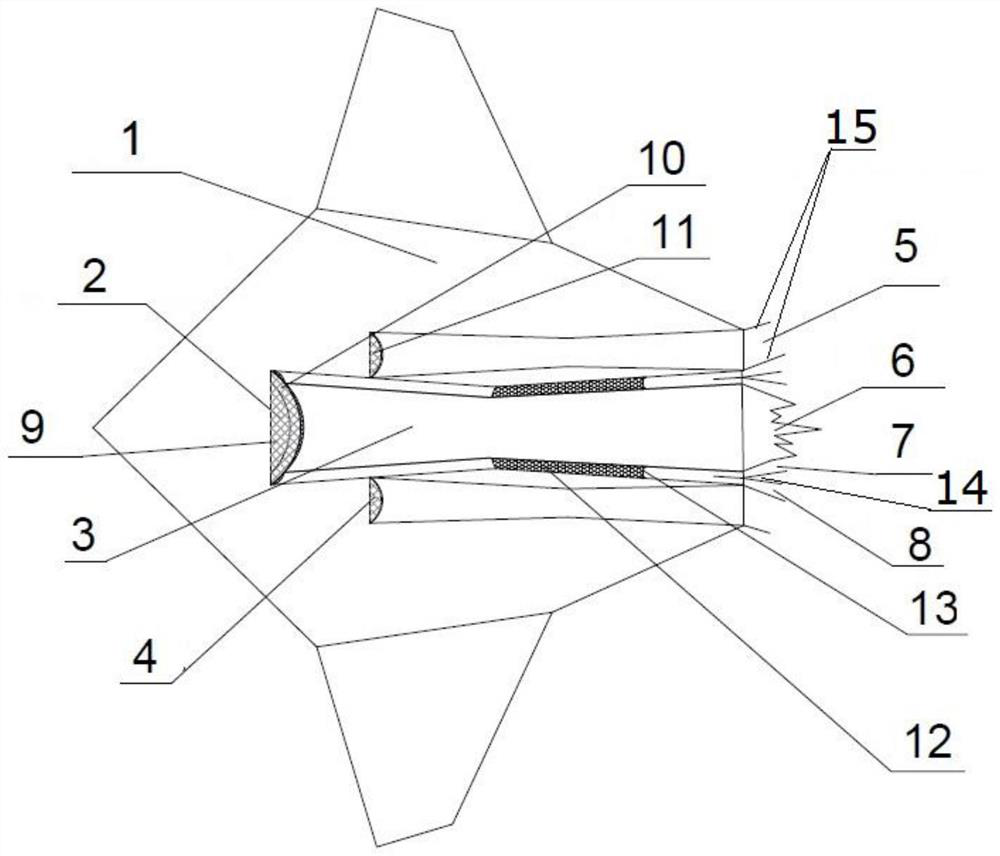

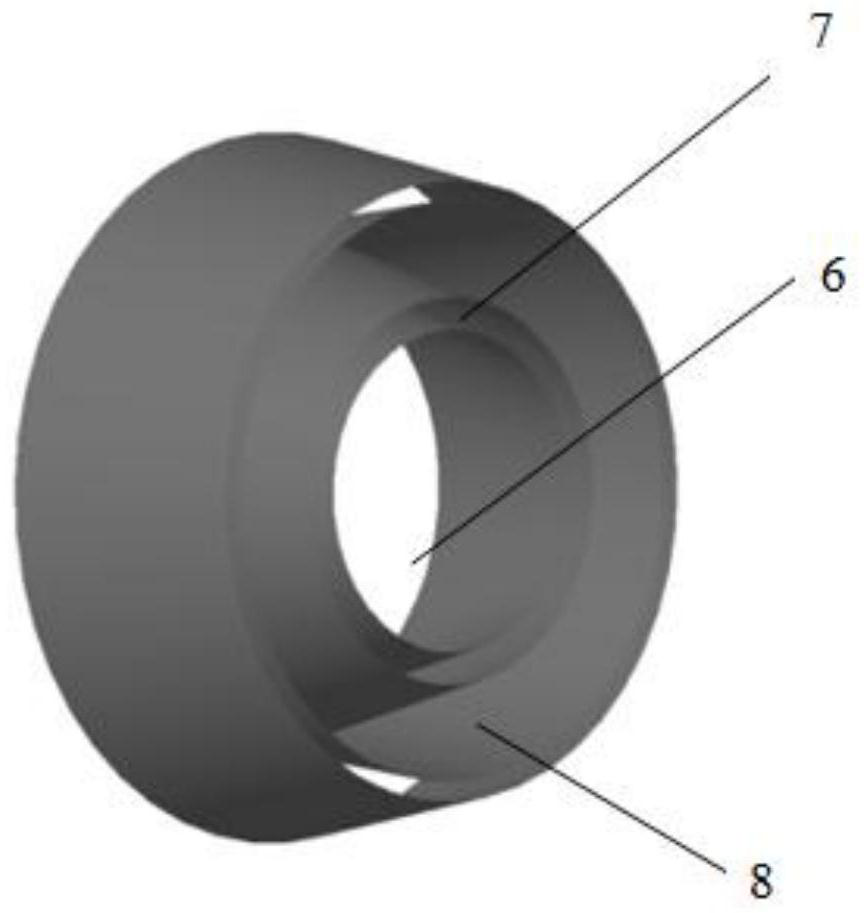

[0091] Innovative design of the injection structure of the material on the aircraft, combined with the fly ash-based zeolite / N-TiO prepared in Example 1 2 The characteristics of composite materials are used as anti-red materials, and the structural design of aircraft is as follows: figure 2 As shown, the injection structure is mainly composed of three parts, which are the fuselage 1, the duct 3 and the heat exchange channel 4. The duct 3 is arranged on the fuselage 1 and wraps the tail flame injection channel. Both sides of the duct 3 are provided with a heat exchange channel 4, and the entrance of the heat exchange channel 4 is located behind the entrance of the duct. The duct 3 is ring-shaped, and the middle interior of the duct 3 is the tail flame 6 injection channel, and the middle interior of the duct 3 is set as the air inlet 2, and an air adjustable baffle 9 can be provided at the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com