Modified beta-cyclodextrin polymer, preparation method and application thereof in dye adsorption

A cyclodextrin polymer and cyclodextrin technology, applied in the field of environmental chemistry, can solve the problems of low adsorption capacity, difficult regeneration, and long adsorption time, and achieve high adsorption capacity, improved adsorption performance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

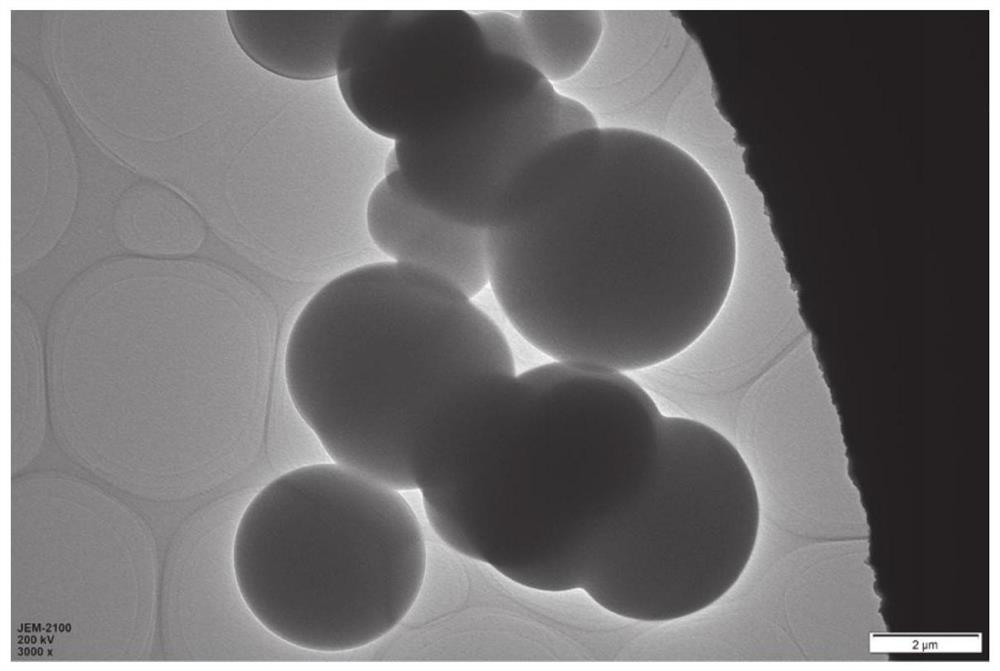

[0045] Mix and dissolve 0.1g of β-cyclodextrin and 0.2g of hexachlorocyclotriphosphazene in 10mL of N,N-dimethylformamide, add 0.15g of potassium carbonate, put it in a 25mL polytetrafluoroethylene reactor, 120°C Constant temperature solvothermal reaction for 24 hours, the reaction is completed, cooling, centrifugation, washing, drying to obtain a light yellow solid.

Embodiment 2

[0047] Mix and dissolve 0.2g of β-cyclodextrin and 0.4g of hexachlorocyclotriphosphazene in 25mL of N,N-dimethylformamide, add 0.2g of potassium carbonate, and place in a 50mL polytetrafluoroethylene reaction kettle at 120°C Constant temperature solvothermal reaction for 48 hours, the reaction was completed, cooled, centrifuged, washed and dried to obtain a black solid.

Embodiment 3

[0049]Mix and dissolve 0.2g of β-cyclodextrin and 0.6g of hexachlorocyclotriphosphazene in 40mL of N,N-dimethylformamide, add 0.3g of potassium carbonate, place in a 100mL round-bottomed flask, reflux at 120°C After 48 hours of reaction, the reaction was completed, cooled, centrifuged, washed, and dried to obtain a light yellow solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com