Preparation method of high-purity rhodium powder

A rhodium powder and high-purity technology, applied in the field of high-purity rhodium powder preparation, can solve complex problems and achieve the effects of rapid preparation and simplified purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

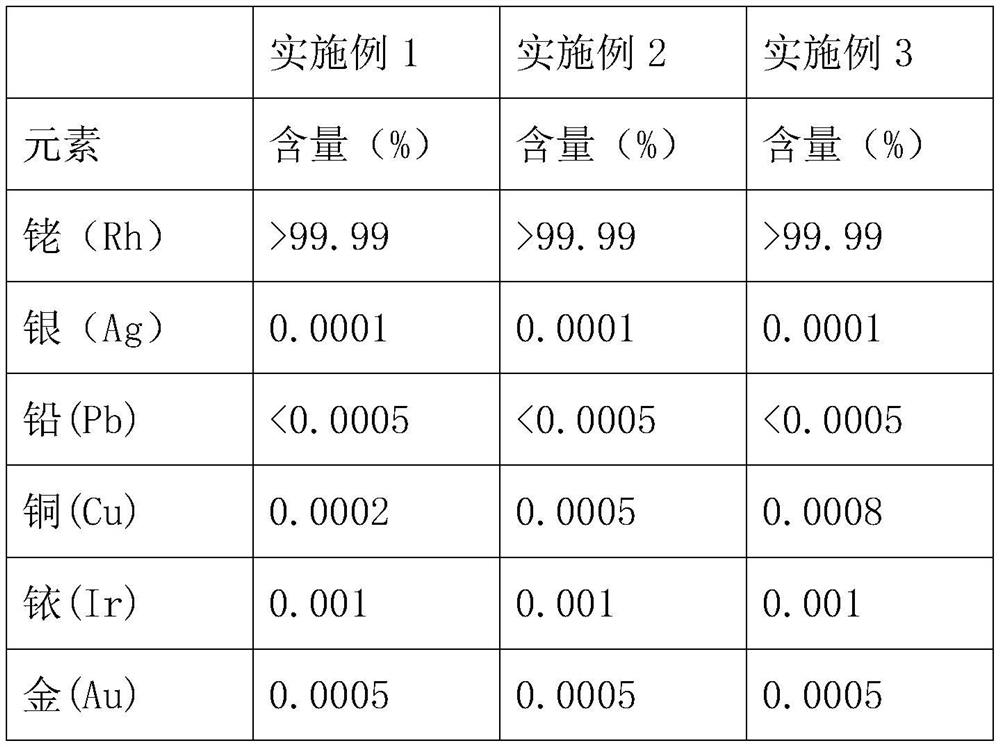

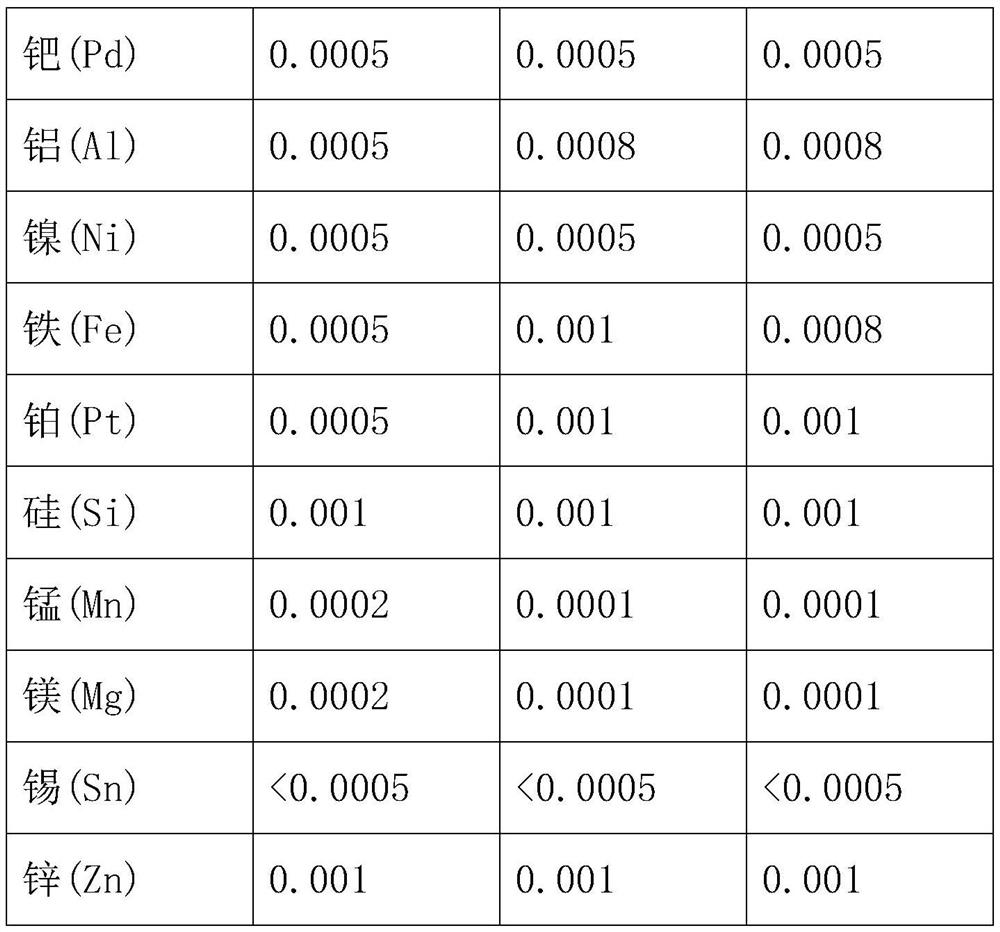

Embodiment 1

[0026] The preparation method of high-purity rhodium powder comprises the following steps:

[0027] Step 1. Dissolve the platinum-rhodium alloy with a mixture of concentrated hydrochloric acid and concentrated nitric acid. After dissolving, heat the solution to remove acid and remove nitrate, and use potassium iodide test paper to determine the degree of nitrate removal. When the potassium iodide test paper is placed for 3 seconds or longer, there is no Proceed to step 2 when the color changes obviously. Among them, the mass ratio of the mixed solution of concentrated hydrochloric acid and concentrated nitric acid to rhodium is 1:1, and the volume ratio of concentrated hydrochloric acid and concentrated nitric acid in the mixed solution of concentrated hydrochloric acid and concentrated nitric acid is 2:1.

[0028] Step 2, adding potassium hydroxide to the solution obtained in step 1 to adjust the pH value to 1-7, and after homogeneous mixing, filter with a Buchner funnel to o...

Embodiment 2

[0034] The preparation method of high-purity rhodium powder comprises the following steps:

[0035] Step 1. Dissolve the platinum-rhodium alloy with a mixture of concentrated hydrochloric acid and concentrated nitric acid. After dissolving, heat the solution to remove acid and remove nitrate, and use potassium iodide test paper to determine the degree of nitrate removal. When the potassium iodide test paper is placed for 3 seconds or longer, there is no Proceed to step 2 when the color changes obviously. Among them, the mass ratio of the mixed solution of concentrated hydrochloric acid and concentrated nitric acid to rhodium is 8:1, and the volume ratio of concentrated hydrochloric acid and concentrated nitric acid in the mixed solution of concentrated hydrochloric acid and concentrated nitric acid is 5:1.

[0036] Step 2, adding sodium hydroxide to the solution obtained in step 1 to adjust the pH value to 1-7, and after homogeneous mixing, filter with a Buchner funnel to obta...

Embodiment 3

[0042] The preparation method of high-purity rhodium powder comprises the following steps:

[0043] Step 1. Dissolve the platinum-rhodium alloy with a mixture of concentrated hydrochloric acid and concentrated nitric acid. After dissolving, heat the solution to remove acid and remove nitrate, and use potassium iodide test paper to determine the degree of nitrate removal. When the potassium iodide test paper is placed for 3 seconds or longer, there is no Proceed to step 2 when the color changes obviously. Wherein, the mass ratio of the mixed solution of concentrated hydrochloric acid and concentrated nitric acid to rhodium is 10:1, and the volume ratio of concentrated hydrochloric acid and concentrated nitric acid in the mixed solution of concentrated hydrochloric acid and concentrated nitric acid is 10:1.

[0044] Step 2, adding ammonia water to the solution obtained in step 1 to adjust the pH value to 1-7, and after homogeneous mixing, filter with a Buchner funnel to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com