Resourceful treatment process for silicon-containing wastewater

A treatment process and resource recovery technology, which is applied in the field of silicon-containing wastewater resource treatment process, can solve the problems of high COD value and process a large amount of waste cutting fluid, and achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

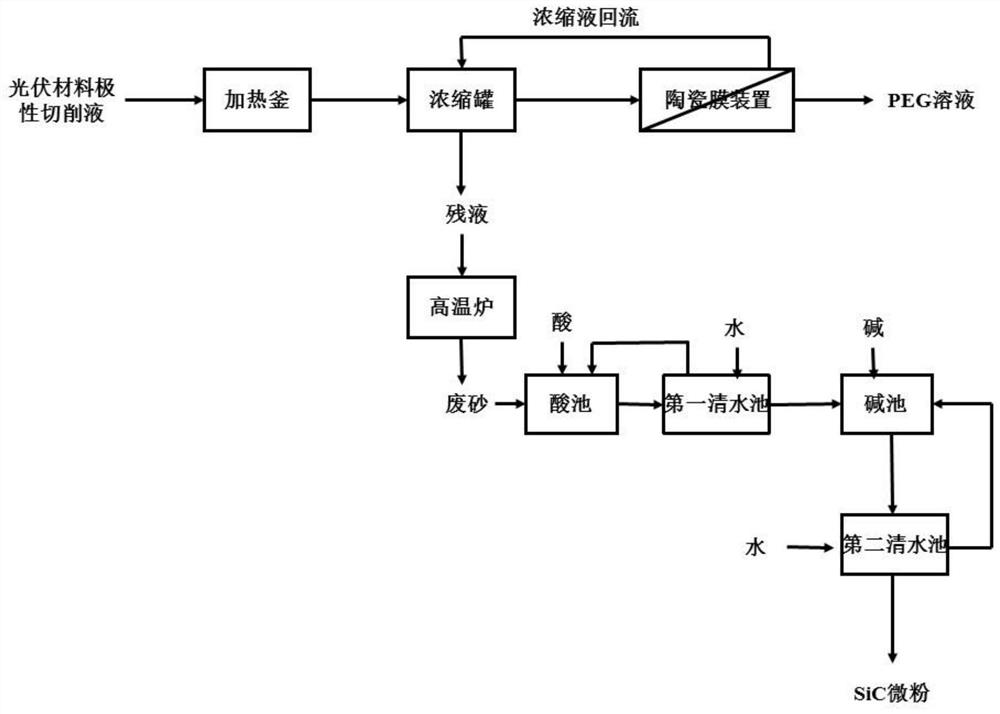

[0026] A resource treatment process for silicon-containing wastewater, comprising:

[0027] (1) Heating and boiling silicon-containing wastewater for 15 to 30 minutes;

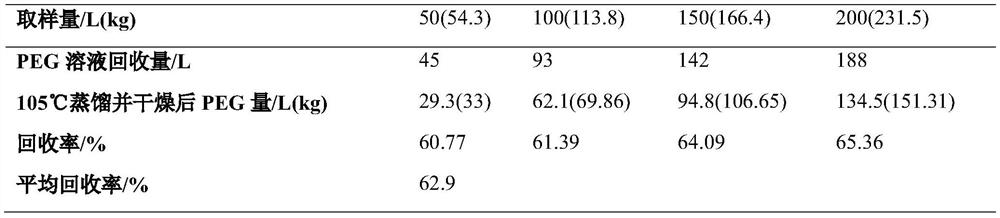

[0028] (2) separating the boiled waste liquid through a ceramic membrane device to obtain a permeate and a concentrate, the permeate is a PEG solution, and the concentrate is a solution with a high suspended solids content;

[0029] (3) the concentrated solution is passed into the concentration tank to concentrate;

[0030] (4) Burn the sludge at the bottom of the thickening tank at high temperature to obtain SiC, Si and Fe-containing 2 o 3 waste sand;

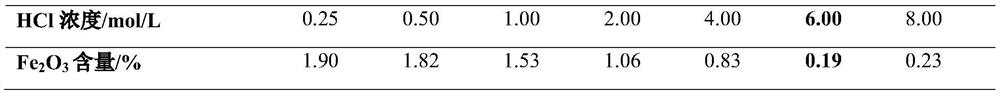

[0031] (5) The waste sand is acid-dissolved and alkali-dissolved successively, and then rinsed and dried to obtain SiC micropowder.

[0032] In step (1): For example, heating is carried out in a heating tank, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com