Method and system for treating waste

A technology for waste and solid waste, applied in special treatment targets, multi-stage water treatment, energy and wastewater treatment, etc. The effect of resource processing, reduction of processing cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

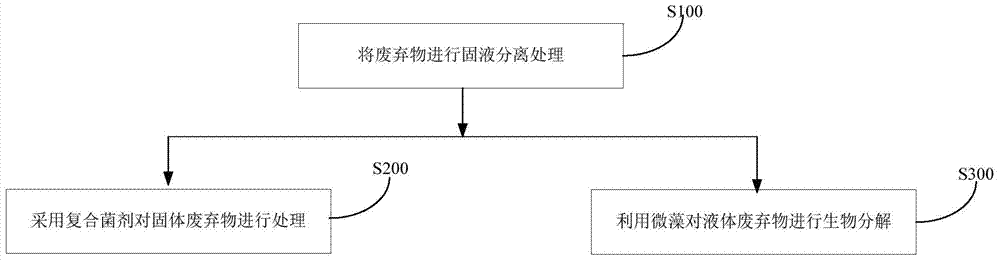

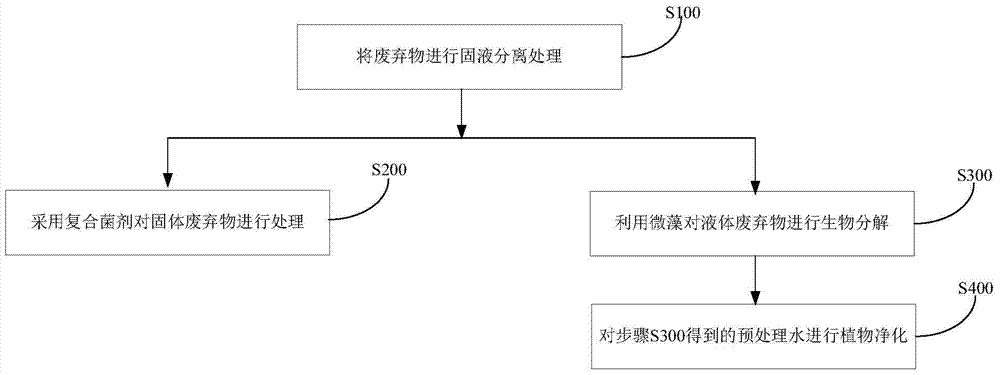

Method used

Image

Examples

Embodiment 1

[0073] The waste disposal system of the embodiment of the present invention is used to process the feces, including the following steps:

[0074] (1) In the solid-liquid separation device, the feces are subjected to solid-liquid separation treatment to obtain solid waste and liquid waste; and the liquid waste is filtered to remove solid particles;

[0075] (2) In the aerobic reaction device, the solid waste is treated with adjuvant oxygen for 12 days by using a composite bacterial agent to obtain organic fertilizer, and the humidity in the aerobic reaction device is controlled to be no more than 85% RH and the temperature to be no more than 60°C;

[0076] (3) In the algae reaction device, microalgae are used to biodegrade the liquid waste for 13 days to obtain pretreated water;

[0077] (4) In the purifying device, the pretreated water obtained in step (3) is subjected to phytopurification for 10 days to obtain purified water.

[0078] Among them, in the aerobic reaction devi...

Embodiment 2

[0080] The waste disposal system of the embodiment of the present invention is used to process the feces, including the following steps:

[0081] (1) In the solid-liquid separation device, the feces are subjected to solid-liquid separation treatment to obtain solid waste and liquid waste; and the liquid waste is filtered to remove solid particles;

[0082] (2) In the aerobic reaction device, the solid waste is treated with aerobic treatment for 17 days by using a composite bacterial agent to obtain organic fertilizer, and the humidity in the aerobic reaction device is controlled to be no more than 85% RH and the temperature to be no more than 60°C;

[0083] (3) In the algae reaction device, microalgae are used to biodegrade the liquid waste for 17 days to obtain pretreated water;

[0084] (4) In the purifying device, the pretreated water obtained in step (3) is subjected to phytopurification for 10 days to obtain purified water.

[0085] Among them, in the facultative oxygen ...

Embodiment 3

[0087] The waste disposal system of the embodiment of the present invention is used to process the feces, including the following steps:

[0088] (1) In the solid-liquid separation device, the feces are subjected to solid-liquid separation treatment to obtain solid waste and liquid waste; and the liquid waste is filtered to remove solid particles;

[0089] (2) In the aerobic reaction device, the solid waste is treated with adjunctive oxygen for 15 days by using a composite bacterial agent to obtain organic fertilizer, and the humidity in the aerobic reaction device is controlled to be no more than 85% RH and the temperature to be no more than 60°C;

[0090] (3) In the algae reaction device, using microalgae to biodegrade the liquid waste for 12 days;

[0091] (4) In the purification device, the liquid waste obtained in step (3) is subjected to phytopurification for 20 days to obtain purified water.

[0092] Among them, in the facultative oxygen reaction device, the compound b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com