Microwave dielectric ceramic material, preparation method thereof and electronic device

A technology of microwave dielectric ceramics and ceramics, applied in the field of ceramic materials, can solve the problems of unsatisfactory, sintering time as long as 48h, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

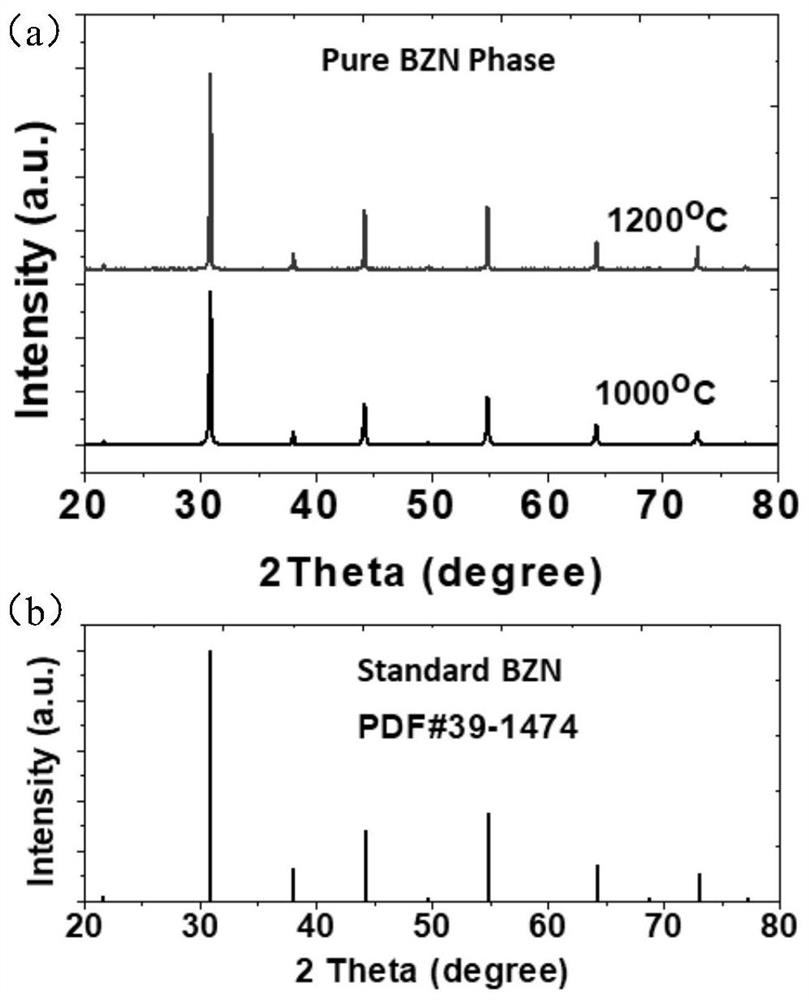

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment adopts 0.8LiF-0.2CaF 2 (abbreviated as L 8 C 2 ) is a composite fluoride sintering aid, which is prepared according to the following steps: according to the required L 8 C 2 LiNO required for mass calculation 3 , Ca(NO 3 ) 2 and accurately weigh it, dissolve it in deionized water to prepare a 0.5mol / L salt solution, and take NH 4 F is dissolved in deionized water to obtain 1.0mol / L NH 4 F solution, drop salt solution into NH 4 The mixed reaction is carried out in the F solution, the mixed suspension is dried at 100°C to obtain a solid mixture, and then the solid mixture is calcined at 300°C in a nitrogen atmosphere to obtain a composite fluoride sintering aid.

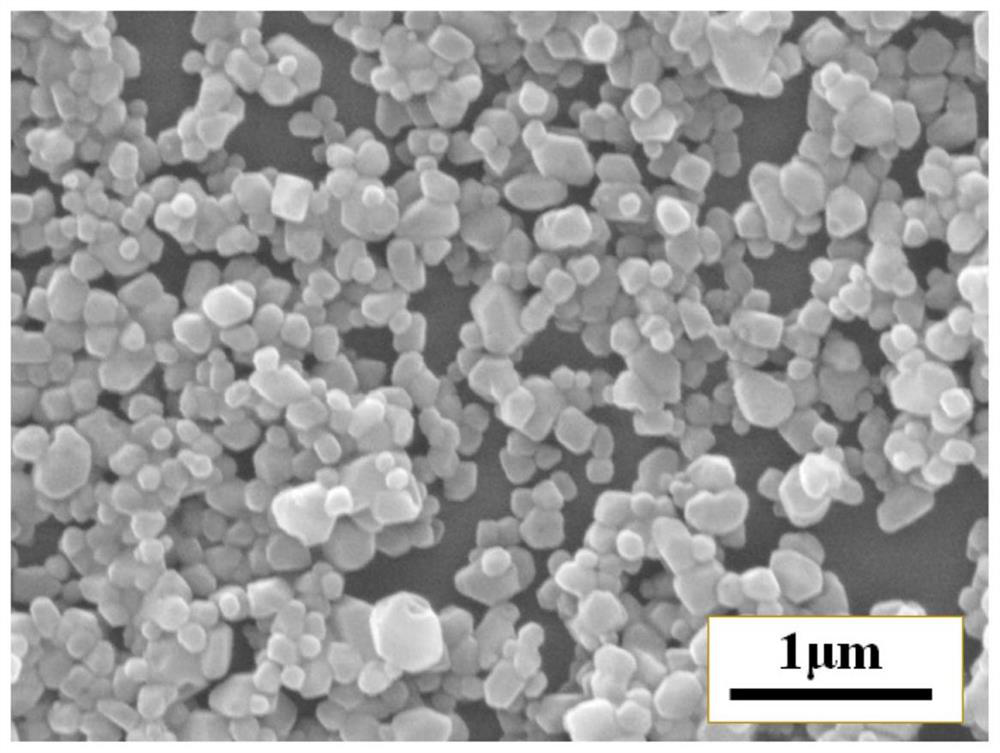

[0038] image 3 The SEM image of the composite fluoride sintering aid prepared in this embodiment is shown, and it can be seen from the figure that the particles of the sintering aid are in nanoscale size.

[0039] With the composite fluoride L prepared above 8 C 2 As a sintering aid,...

Embodiment 2

[0045] This embodiment provides a microwave dielectric ceramic material, and the sintering aid used in the preparation process is the L prepared in Example 1. 8 C 2 The composite fluoride sintering aid is specifically prepared according to the following steps:

[0046] S1, BZN main material and compound fluoride sintering aid L 8 C 2 Accurately weighed according to the formula, wherein the mass percentage of BZN main material is 95wt.%, L 8 C 2 The mass percentage is 5wt.%.

[0047] S2. Put the raw material weighed in step S1 into a ball mill tank for ball milling, wherein the mass ratio of raw material powder: dispersant: ball milling medium = 1:2:7, the dispersant is absolute ethanol, and the ball milling medium is zirconia Balls were ball milled for 8 hours at 300-500 rpm on a planetary ball mill.

[0048] S3. Dry the slurry obtained by ball milling in step S2 at 75° C., grind and pass through a 200-mesh sieve to obtain the required powder.

[0049] S4. Dry press the...

Embodiment 3

[0051] This embodiment uses 0.8LiF-0.2BaF 2 (abbreviated as L 8 B 2 ) is a composite fluoride sintering aid, which is prepared according to the following steps: similar to Example 1, weigh LiNO 3 and BaCl 2 Dissolve in deionized water to form a salt solution with a cation concentration of 0.5mol / L, and take NH 4 F is dissolved in deionized water to obtain 1.0mol / L NH 4 F solution, drop salt solution into NH 4 The mixed reaction is carried out in the F solution, the mixed suspension is dried at 100°C to obtain a solid mixture, and then the solid mixture is calcined at 250°C in a nitrogen atmosphere to obtain a composite fluoride sintering aid.

[0052] With the composite fluoride L prepared above 8 B 2 As a sintering aid, the microwave dielectric ceramic material is prepared according to the following steps:

[0053] S1, BZN main material and compound fluoride sintering aid L 8 B 2 Accurately weighed according to the formula, wherein the mass percentage of BZN main ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com