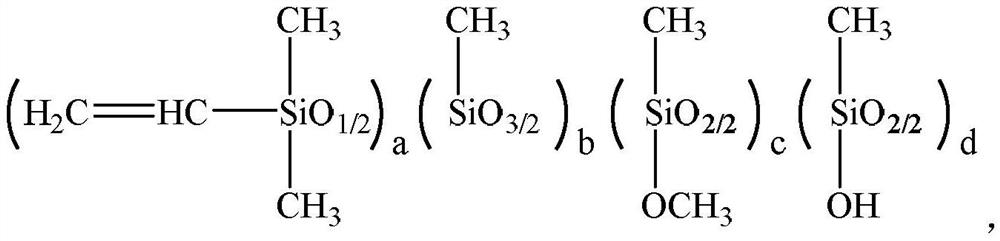

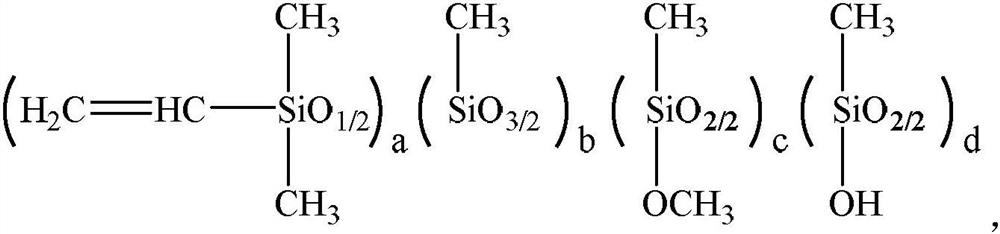

Preparation method of dimethylvinylsiloxy-terminated MDT silicone oil with low hydroxyl content

A technology of dimethylvinylsiloxane sealing and divinyl, which is applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc. It can solve the problem of air bubbles in the release agent and affect the curing rate of the release agent and poor quality, poor storage stability of silicone oil, etc., to achieve the effect of simple preparation process, uniform molecular weight distribution of silicone oil, and low silicon hydroxyl content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Add 727.20g (3.90mol) of 1,3-divinyl-1,1,3,3-tetramethyldisilazium to a 3000mL three-necked flask equipped with a stirring device, a thermometer and a reflux condenser at room temperature Oxygen, the temperature was raised to 35°C under stirring, and then the mixed solution consisting of 702.00g (39.0mol) of deionized water and 62.88g (0.637mol) of concentrated HCl with a concentration of 37% was mixed for 2h through a constant pressure dropping funnel. Add it dropwise to the reaction vessel at a constant speed. After the dropwise addition, raise the temperature of the reactant to 70° C. and react at this temperature for 3 hours. After the reaction was finished, it was cooled to room temperature, and the reaction product was two layers up and down;

[0039] (2) Add 531.60g (3.90mol) of methyltrimethoxysilane and 314.40g of toluene into another 5000mL three-necked flask equipped with a stirring device, a thermometer and a reflux condenser, and keep the system tempera...

Embodiment 2

[0043] (1) Add 727.20 g (3.90 mol) of 1,3-divinyl-1,1,3,3-tetramethyldisilazium to a 3000 mL three-necked flask equipped with a stirring device, a thermometer and a reflux condenser at room temperature Oxygen, under stirring, be warmed up to 45 ℃, then through the constant pressure dropping funnel, the mixed solution that the premixed 702.00g (39.0mol) deionized water and 62.88g (0.637mol) concentration is the concentrated HCl composition of 37% is passed through 2.5 h was added dropwise to the reaction vessel at a constant speed. After the dropwise addition, the temperature of the reactant was raised to 70° C. and reacted at this temperature for 3 h. After the reaction was finished, it was cooled to room temperature, and the reaction product was two layers up and down;

[0044] (2) Add 531.60g (3.90mol) of methyltrimethoxysilane and 314.40g of toluene to another 5000mL three-necked flask equipped with a stirring device, a thermometer and a reflux condenser, and keep the syste...

Embodiment 3

[0048] (1) Add 181.80 g (0.975 mol) of 1,3-divinyl-1,1,3,3-tetramethyldisilazium to a 1000 mL three-necked flask equipped with a stirring device, a thermometer and a reflux condenser at room temperature Oxygen, the temperature was raised to 30°C under stirring, and then the mixed solution composed of 175.50g (9.75mol) deionized water and 15.72g (0.159mol) concentration of 37% concentrated HCl was passed through a constant pressure dropping funnel through 0.75 h was added dropwise to the reaction vessel at a constant speed. After the dropwise addition, the temperature of the reactant was raised to 65° C. and reacted at this temperature for 4 hours. After the reaction was finished, it was cooled to room temperature, and the reaction product was two layers up and down;

[0049] (2) Add 132.90g (0.976mol) of methyltrimethoxysilane and 78.60g of toluene to another 1000mL three-necked flask equipped with a stirring device, a thermometer and a reflux condenser, and keep the system te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com