A kind of non-tiger pattern polypropylene composite material and preparation method thereof

A composite material and tiger skin pattern technology, applied in the field of non-tiger skin pattern polypropylene composite material and its preparation, can solve the problems of decreased toughness of composite materials, incompatibility of fluidity and toughness, and inability to achieve covering effect, etc. Melt strength, the effect of solving tiger skin defects, and resisting shear and tensile deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

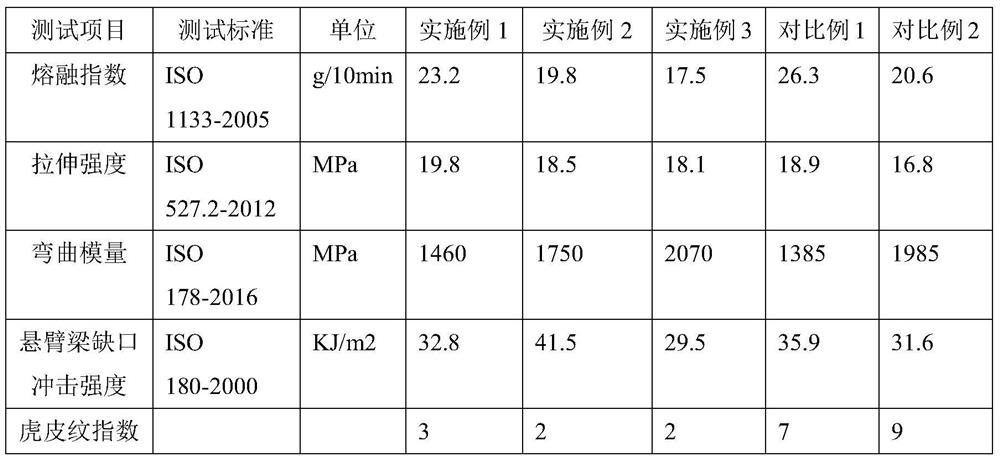

Examples

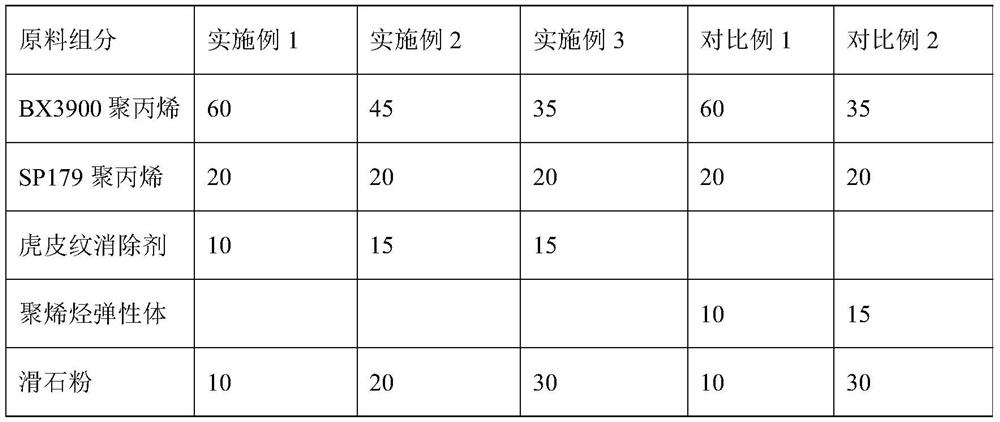

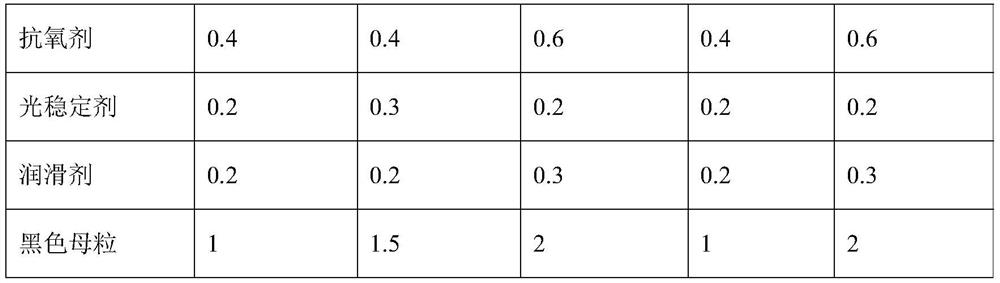

Embodiment 1

[0039] S1: Fully mix 1 part of styrene, 39 parts of polyolefin elastomer and 156 parts of liquid carbon tetrachloride, then add 0.05 part of initiator and 0.05 part of crosslinking agent, fill the reaction kettle with nitrogen protection, and mechanically stir and mix at room temperature Uniform;

[0040] S2: Raise the temperature of the reaction kettle to 65° C., continue stirring for 8 hours, remove the solvent, and prepare the tiger-stripe eliminating agent.

[0041] S3: Weigh 60 parts of BX3900 polypropylene, 20 parts of SP179 polypropylene, 10 parts of tiger stripe remover, 10 parts of talcum powder, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, 0.2 parts of lubricant, 0.2 parts The light stabilizer and 1 part of black masterbatch are fully mixed and stirred at a high speed to obtain a well-mixed blend;

[0042] S4: put the blend obtained in step S3 into a twin-screw extruder, the screw speed of the twin-screw extruder is 400r / min, and the vacuum degree du...

Embodiment 2

[0044] S1: Fully mix 1 part of styrene, 39 parts of polyolefin elastomer and 156 parts of liquid carbon tetrachloride, then add 0.1 part of initiator and 0.1 part of crosslinking agent, fill the reaction kettle with nitrogen protection, and mechanically stir and mix at room temperature Uniform;

[0045] S2: Raise the temperature of the reaction kettle to 85° C., continue stirring for 9 hours, remove the solvent, and prepare the tiger-stripe eliminating agent.

[0046]S3: Weigh 45 parts of BX3900 polypropylene, 20 parts of SP179 polypropylene, 15 parts of tiger stripe remover, 20 parts of talcum powder, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.2 part of lubricant, 0.3 part The light stabilizer and 1.5 parts of black masterbatch are fully mixed and stirred at high speed to obtain a well-mixed blend;

[0047] S4: put the blend obtained in step S3 into a twin-screw extruder, the screw speed of the twin-screw extruder is 450r / min, and the vacuum degree during e...

Embodiment 3

[0049] S1: Fully mix 1 part of styrene, 39 parts of polyolefin elastomer and 156 parts of liquid carbon tetrachloride, then add 0.07 part of initiator and 0.07 part of crosslinking agent, fill the reaction kettle with nitrogen protection, and mix mechanically at room temperature Uniform;

[0050] S2: Raise the temperature of the reaction kettle to 75° C., continue stirring for 10 hours, remove the solvent, and prepare the tiger-stripe eliminating agent.

[0051] S3: Weigh 35 parts of BX3900 polypropylene, 20 parts of SP179 polypropylene, 15 parts of tiger stripe remover, 30 parts of talcum powder, 0.3 part of antioxidant 1010, 0.3 part of antioxidant 168, 0.3 part of lubricant, 0.2 part The light stabilizer and 2 parts of black masterbatch are fully mixed and stirred at a high speed to obtain a well-mixed blend;

[0052] S4: put the blend obtained in step S3 into a twin-screw extruder, the screw speed of the twin-screw extruder is 425r / min, and the vacuum degree during extrus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com