A high-efficiency coal gasification reaction device and high-efficiency coal gasification reaction method

A reaction device and coal gasification technology, applied in the field of coal gasification, can solve the problems of low system energy conversion rate, energy consumption, and long process, so as to improve reaction efficiency and carbon conversion rate, increase mass transfer and heat transfer, and increase The effect of gasification progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

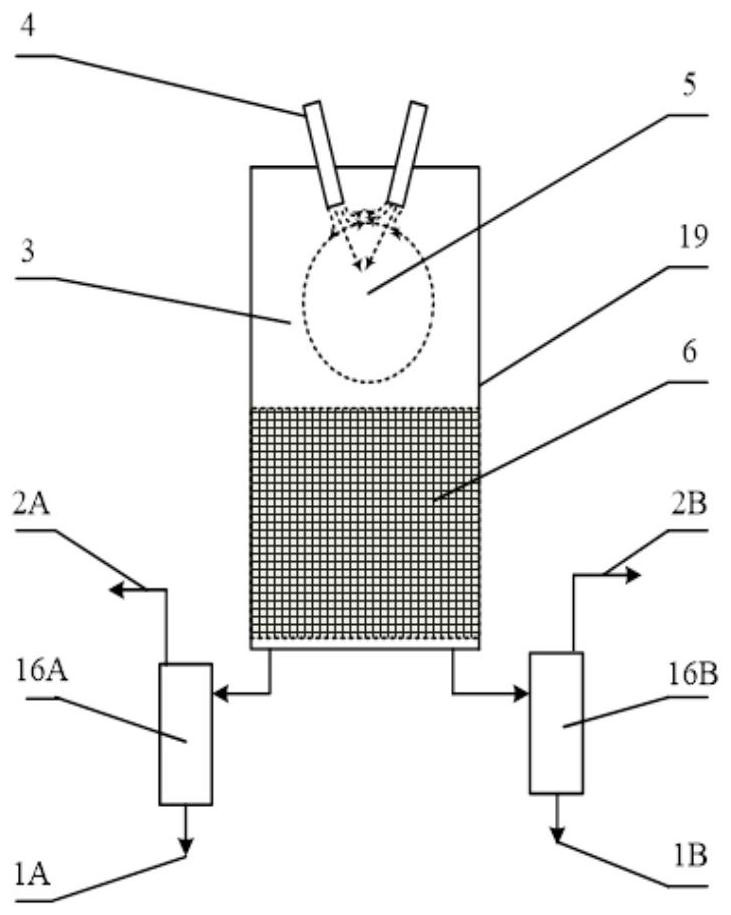

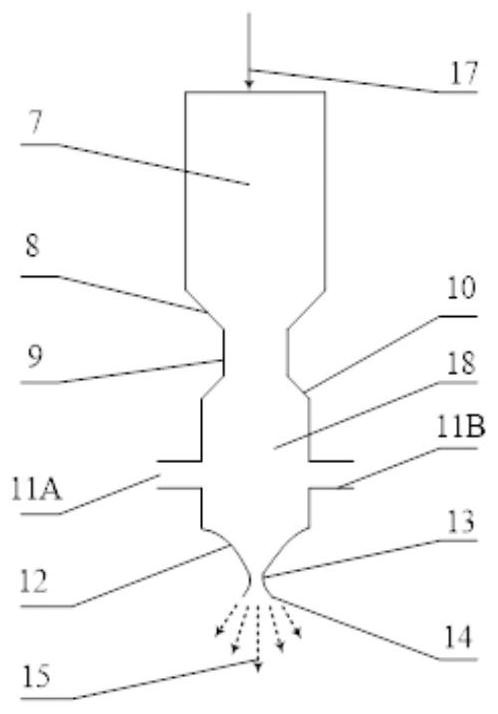

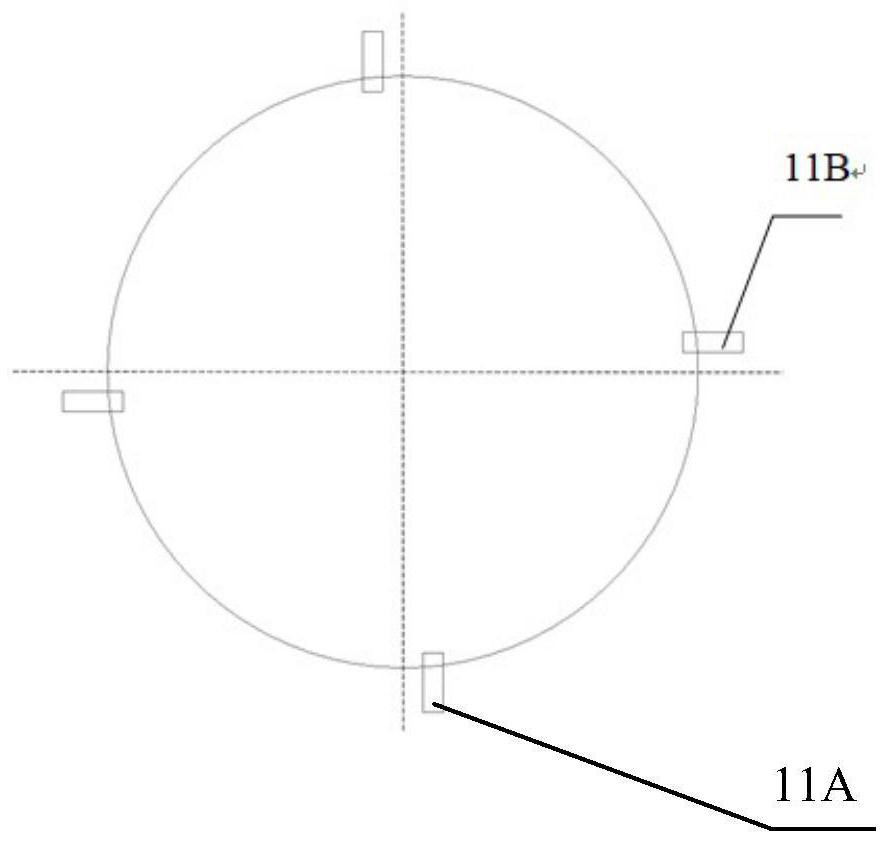

[0033] Such as Figure 1-3 , high-efficiency coal gasification reaction device, the device includes:

[0034] Coal gasification gasifier 19, oxygen coal gun 4, cyclone separator 16A and cyclone separator 16B;

[0035] The coal gasification gasifier 19 includes the upper space 3 of the gasifier and the coke filling area 6 at the lower part of the gasifier distributed up and down. The upper space 3 of the gasifier communicates with the coke filling area 6 at the lower part of the gasifier. The gasifier upper space 3 on the upper part of the gasifier 19 is connected; the cyclone separator is connected with the coke filling area 6 at the lower part of the gasifier; Gun upper space 7, oxygen coal gun gas reducer upper part 8, oxygen coal gun gas reducer middle part 9, oxygen coal gun gas reducer lower part 10, coal gun mixed material reducer upper part 12, oxygen coal gun mixed material The middle part 13, the lower part 14 of the mixed material of the oxygen-coal gun and the out...

Embodiment 2

[0045] Such as Figure 1-3 , high-efficiency coal gasification reaction device, the device includes:

[0046] Coal gasification gasifier 19, oxygen coal gun 4, cyclone separator 16A and cyclone separator 16B;

[0047] The coal gasification gasifier 19 includes the upper space 3 of the gasifier and the coke filling area 6 at the lower part of the gasifier distributed up and down. The upper space 3 of the gasifier communicates with the coke filling area 6 at the lower part of the gasifier. The gasifier upper space 3 on the upper part of the gasifier 19 is connected; the cyclone separator is connected with the coke filling area 6 at the lower part of the gasifier; Gun upper space 7, oxygen coal gun gas reducer upper part 8, oxygen coal gun gas reducer middle part 9, oxygen coal gun gas reducer lower part 10, coal gun mixed material reducer upper part 12, oxygen coal gun mixed material The middle part 13, the lower part 14 of the mixed material of the oxygen-coal gun and the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com