Pineapple fruit beer and preparation method thereof

A technology for pineapple and fruit beer, which is applied to the field of pineapple fruit beer and its preparation, can solve the problems of complex production process, overshoot of essence and flavor, insufficient aroma and freshness, etc., and achieves high nutritional value, soft taste, and avoids overshoot of essence. The effect of taste and incongruous taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

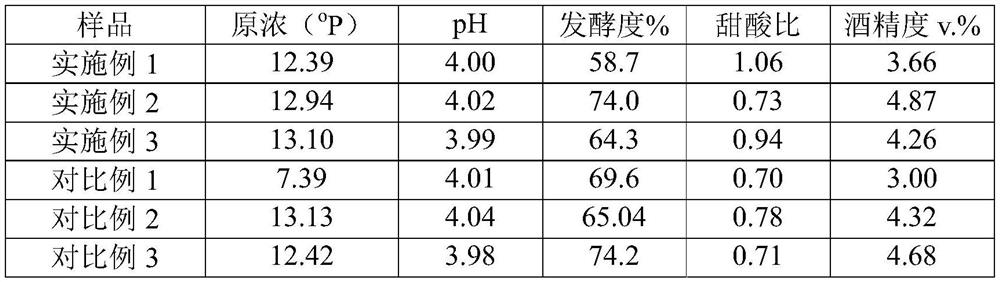

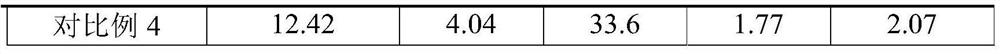

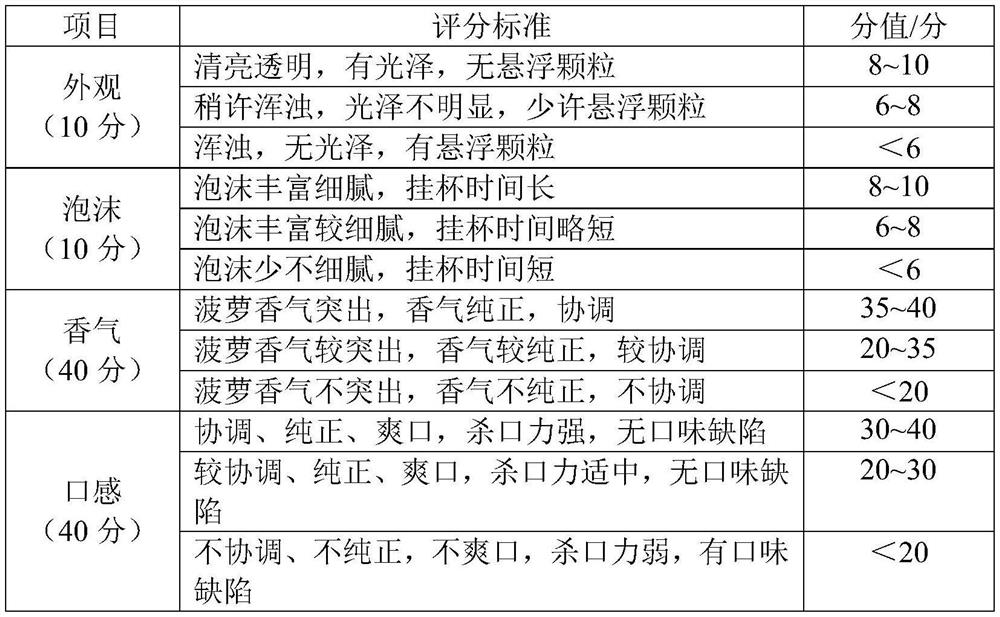

Examples

Embodiment 1

[0040] A kind of pineapple fruit beer is prepared by the following method:

[0041](1) Peel and remove the core of the fresh and ripe pineapple without disease, cut into small pieces of uniform size, beat the pulp, pass through the 1.6mm sieve and the 0.8mm sieve quickly after the beating, and then pass through the 180bar high-pressure homogenizer Carry out homogenization; the homogeneous slurry is quickly placed under 10kPa for vacuum degassing to prevent browning of the pineapple juice; instant sterilization at 105°C, immediately cool down to 2-4°C, filter with a 1μm microporous membrane, clarify, Get the pineapple juice and set aside.

[0042] (2) Separately pulverize light-colored imported malt and rice to obtain malt powder and rice flour. Take 0.6kg of rice flour and add 2.3L of brewing water, add 0.18g of high temperature-resistant α-amylase, heat up to 73°C for 10 minutes, heat up to 95°C and rest for 35 minutes to obtain gelatinized mash for later use. Take 1.4kg of...

Embodiment 2

[0047] A kind of pineapple fruit beer is prepared by the following method:

[0048] (1) Peel and remove the core of the fresh and ripe pineapple without disease, cut into small pieces of uniform size, beat the pulp, pass through the 1.6mm sieve and the 0.8mm sieve quickly after the beating, and then pass through the 180bar high-pressure homogenizer Carry out homogenization; the homogeneous slurry is quickly placed under 10kPa for vacuum degassing to prevent browning of the pineapple juice; instant sterilization at 105°C, immediately cool down to 2-4°C, filter with a 1μm microporous membrane, clarify, Get the pineapple juice and set aside.

[0049] (2) Separately pulverize light-colored imported malt and rice to obtain malt powder and rice flour. Take 0.6kg of rice flour and add 2.3L of brewing water, add 0.18g of high temperature-resistant α-amylase, heat up to 73°C for 10 minutes, heat up to 95°C and rest for 35 minutes to obtain gelatinized mash for later use. Take 1.4kg o...

Embodiment 3

[0054] A kind of pineapple fruit beer is prepared by the following method:

[0055] (1) Peel and remove the core of the fresh and ripe pineapple without disease, cut into small pieces of uniform size, beat the pulp, pass through the 1.6mm sieve and the 0.8mm sieve quickly after the beating, and then pass through the 180bar high-pressure homogenizer Carry out homogenization; the homogeneous slurry is quickly placed under 10kPa for vacuum degassing to prevent browning of the pineapple juice; instant sterilization at 105°C, immediately cool down to 2-4°C, filter with a 1μm microporous membrane, clarify, Get the pineapple juice and set aside.

[0056] (2) Separately pulverize light-colored imported malt and rice to obtain malt powder and rice flour. Take 0.6kg of rice flour and add 2.3L of brewing water, add 0.18g of high temperature-resistant α-amylase, heat up to 73°C for 10 minutes, heat up to 95°C and rest for 35 minutes to obtain gelatinized mash for later use. Take 1.4kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com