Polarization beam splitter structure and polarization beam splitting method

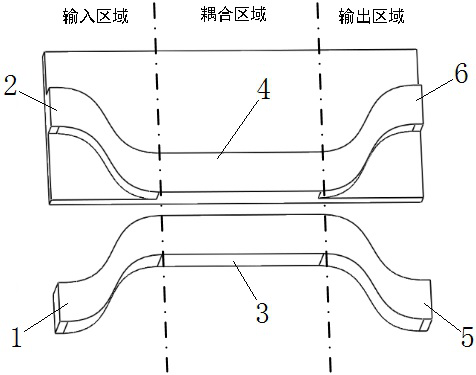

A polarization beam splitter and coupling waveguide technology, which is applied in the direction of instruments, light guides, optics, etc., can solve the problems of high manufacturing requirements of nano-groove structures, deterioration of photonic integrated device performance, and impossible elimination of birefringence phenomenon, etc., and meet the technical requirements Not harsh, simple structure, low insertion loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

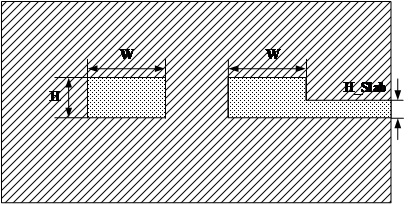

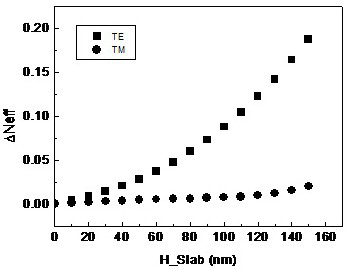

Embodiment 1

[0036] The material of the designed waveguide structure is silicon with a refractive index of 3.455, and the buffer layer and upper cover layer are silicon dioxide with a refractive index of 1.445. The height H of the bar-shaped straight waveguide structure is 220nm, and the width W is 450nm, and the height H of the ridge-shaped straight waveguide structure is 220nm, and the width is 450nm. The difference in refractive index (△Neff) between the TE mode and the TM mode of the ridge straight waveguide and the strip straight waveguide calculated by the finite element analysis method varies with the height of the slab region (H_Slab) as follows image 3 As shown, the strip straight waveguide structure corresponds to the case of H_Slab=0. It can be seen that with the increase of H_Slab, the refractive index of the TE mode increases gradually, and the difference between the refractive index of the TE mode and the strip straight waveguide becomes larger, while the change of the refra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com