Rolling type shaping and grading integrated machine

An all-in-one machine and rolling mill technology, which is applied in solid separation, filter screen, grille, etc., can solve the problems of high noise in equipment operation, powder failure, dust leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

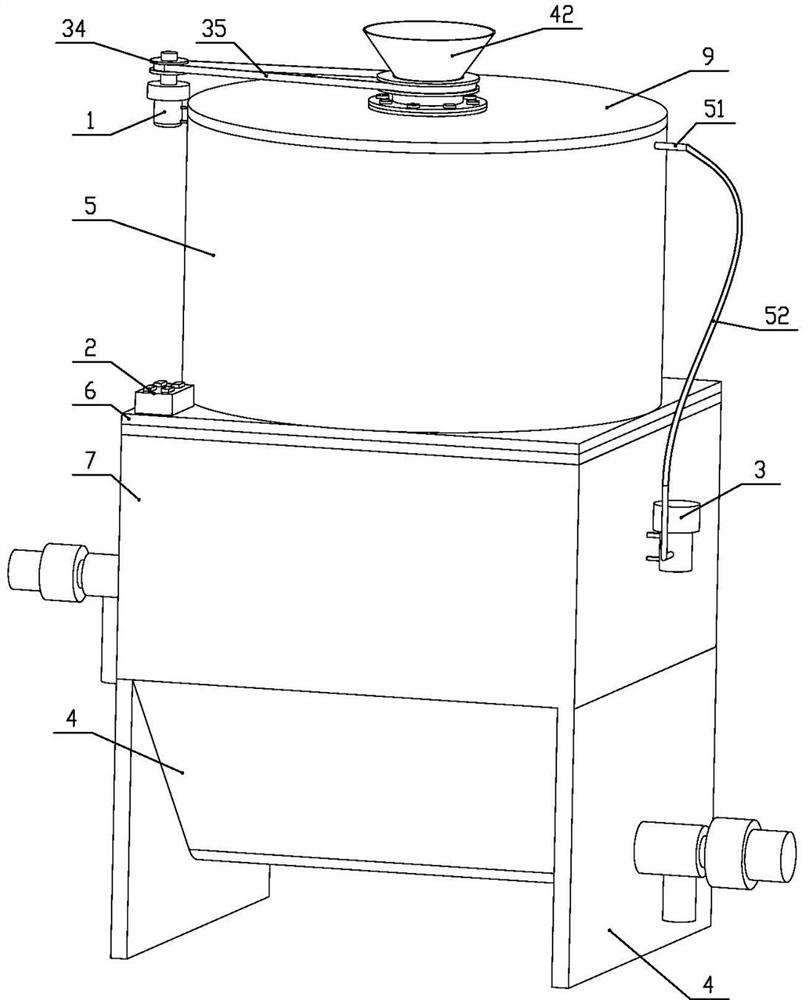

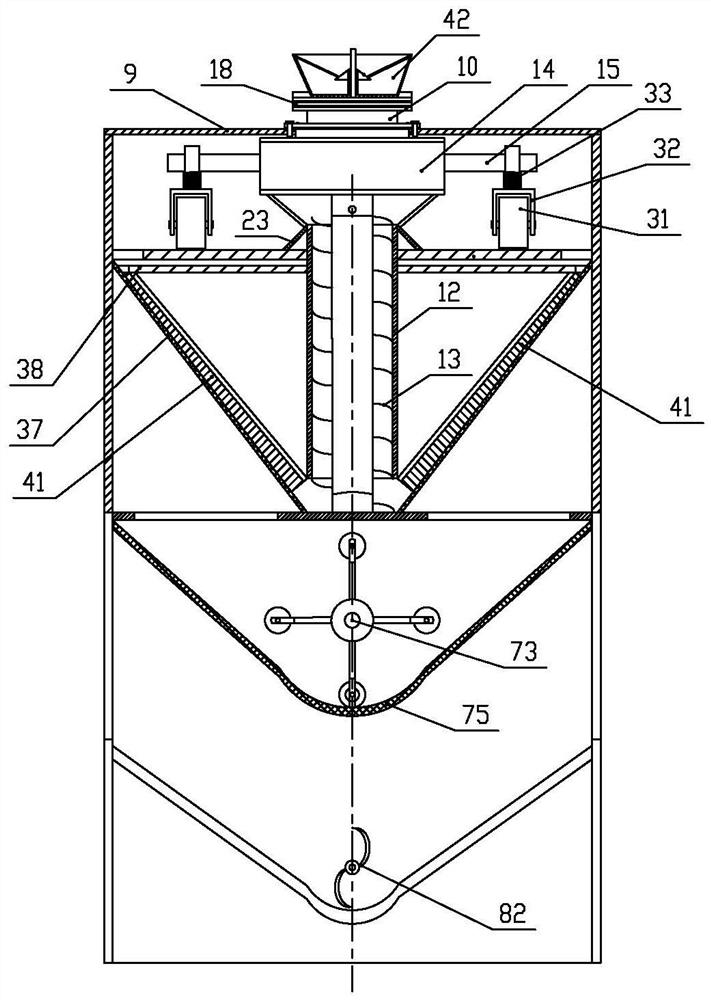

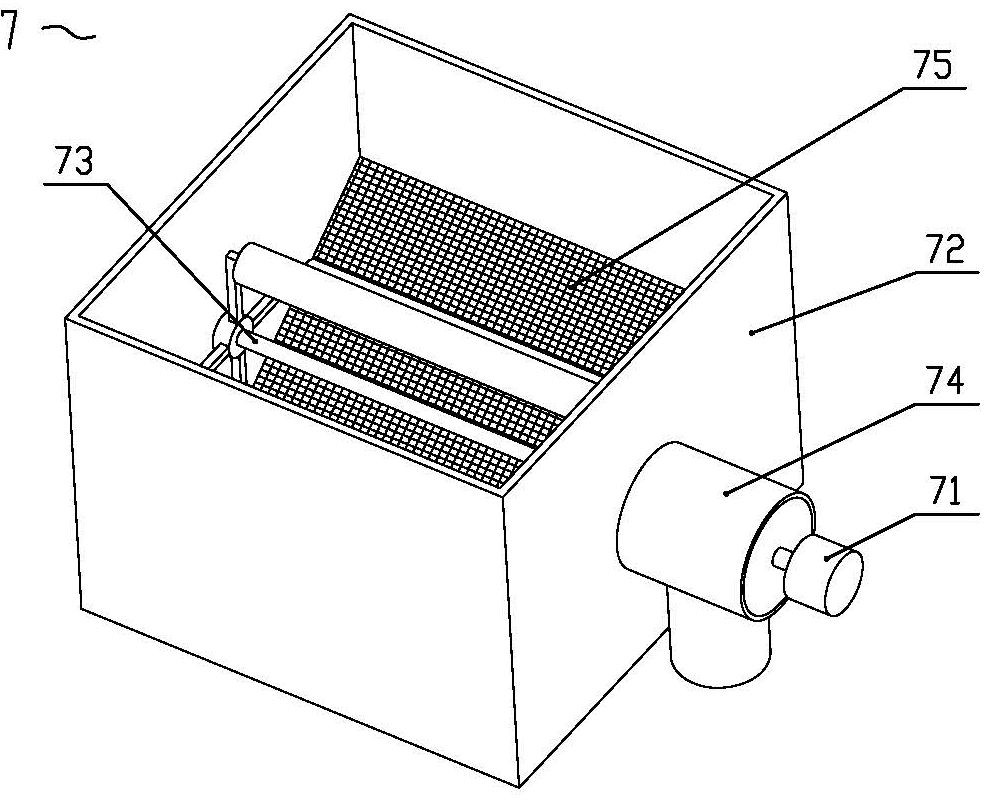

Embodiment 1

[0039]The present invention is used for shaping and grading metal silicon powder of 800-1400 meshes (that is, grinding off the sharp corners and burrs of metal silicon powder, and separating and removing the sharp corners and burrs at the same time to improve the size and shape of the powder. The purpose of uniformity. Because the metal silicon powder is easy to produce sparks when it is crushed under air conditions, there are potential safety hazards in shaping, and the vacuum sealing operation can improve safety). Connected and assembled, at the same time, connect an external airtight plastic material finished product storage container with the discharge opening of the star discharge valve 74; The fine particle discharge pipe 83 is airtightly connected. The total height of the present invention is 2480mm, and the power of the speed-regulating motor 1 that is adopted is 2000 watts, and the rotating speed of the speed-regulating motor 1 is 150 rpm, and the outer diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com