Method for deeply removing arsenic in waste SCR catalyst acid system

A technology of SCR catalyst and acidic system, applied in chemical instruments and methods, separation methods, solid waste removal, etc., can solve the problems of reducing investment and operating costs, low arsenic removal efficiency, etc., achieve simple process flow, avoid waste brine , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

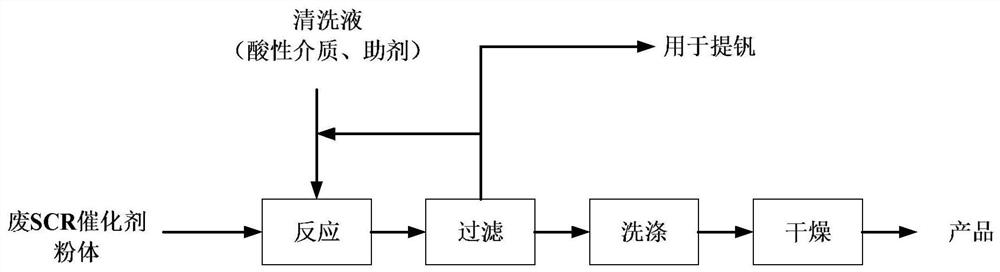

Method used

Image

Examples

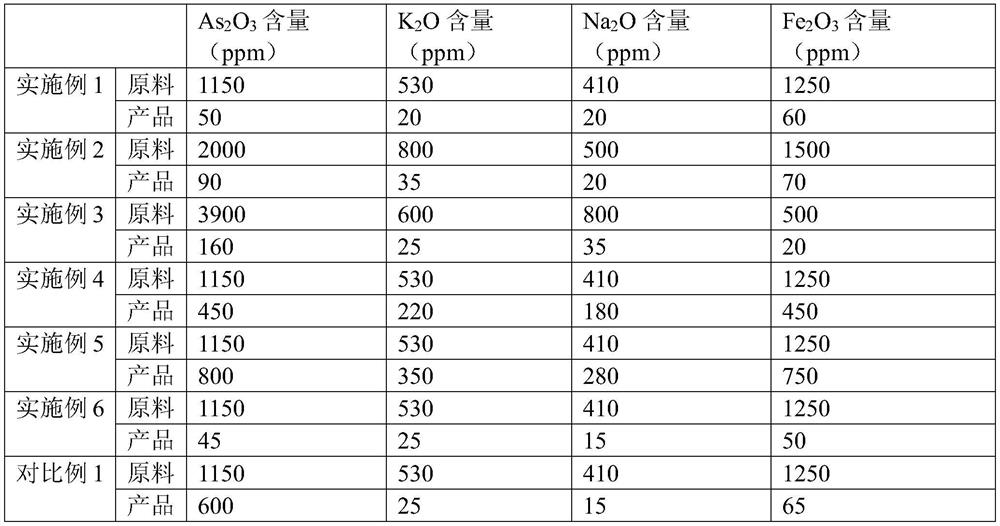

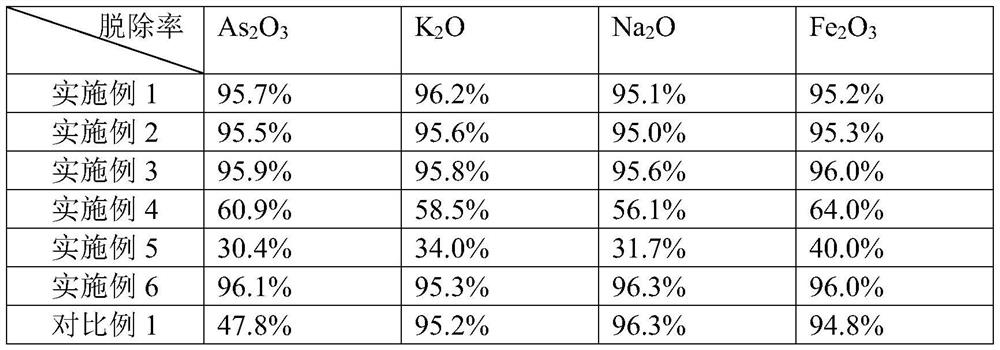

Embodiment 1

[0035] This embodiment provides a method for deep arsenic removal in an acidic system of a spent SCR catalyst, the method comprising the following steps:

[0036] (1) Grinding the waste SCR catalyst after deashing, then adding the waste SCR catalyst powder into the cleaning liquid containing 10% sulfuric acid and 1% sodium sulfide, the mass ratio of the cleaning liquid to the waste SCR catalyst powder 2:1, after reacting at 30°C for 3h, filter;

[0037] (2) washing and drying the solid phase obtained by filtration to obtain the product.

Embodiment 2

[0039] This embodiment provides a method for deep arsenic removal in an acidic system of a spent SCR catalyst, the method comprising the following steps:

[0040] (1) Grinding the waste SCR catalyst after deashing, then adding the waste SCR catalyst powder into the cleaning solution containing 15% hydrochloric acid and 0.5% potassium thiosulfate, the difference between the cleaning solution and the waste SCR catalyst powder The mass ratio is 10:1, after reacting at 60°C for 6 hours, filter;

[0041] (2) washing and drying the solid phase obtained by filtration to obtain the product.

Embodiment 3

[0043] This embodiment provides a method for deep arsenic removal in an acidic system of a spent SCR catalyst, the method comprising the following steps:

[0044] (1) Grinding the waste SCR catalyst after deashing, then adding the waste SCR catalyst powder into the cleaning liquid containing 11% oxalic acid and 2% sodium sulfite, the mass ratio of the cleaning liquid and the waste SCR catalyst powder is 8:1, after reacting at 100°C for 8 hours, filter;

[0045] (2) washing and drying the solid phase obtained by filtration to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com