A carbon fiber reinforced composite material with high interfacial strength and strong interfacial conductivity and its preparation method

A technology to enhance composite materials and interface strength, applied in the field of carbon fiber resin matrix composite materials, can solve the problems of poor interface bonding of composite materials, weak conductivity of composite material interfaces, etc., and achieve a controllable, simple and efficient self-assembly process, and can improve The effect of adding amount and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

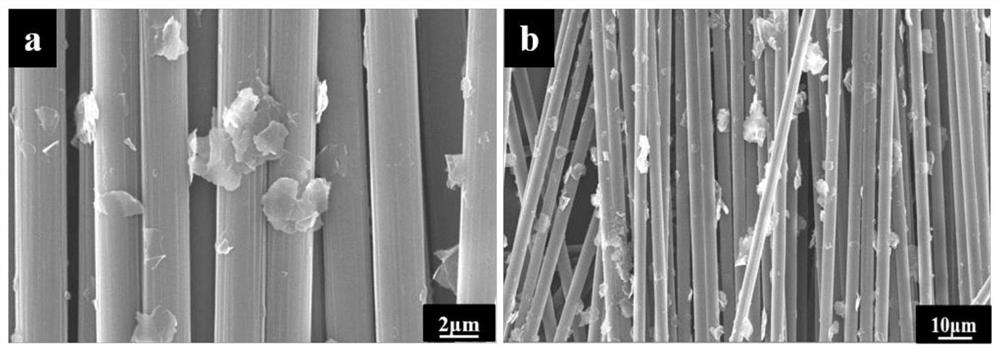

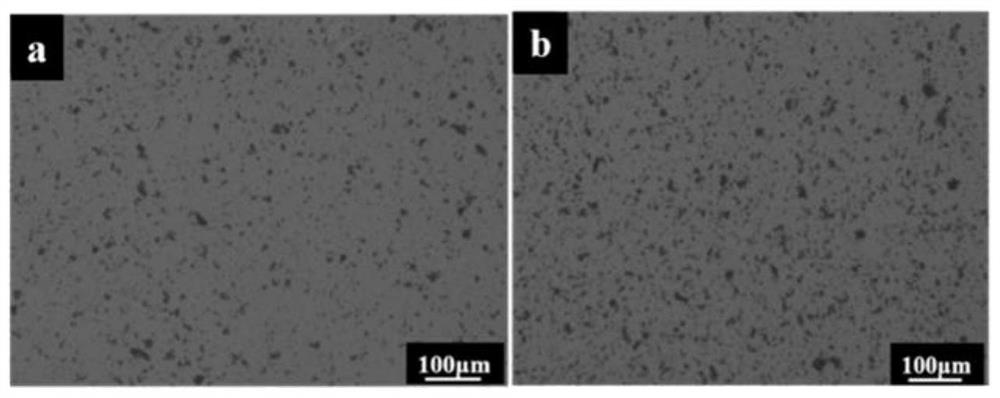

Embodiment 1

[0027] The mass fractions of epoxy resin, amine curing agent, accelerator and nanoparticles are prepared according to the ratio of 100:30:0.5:0.5. The epoxy resin adopts the compound of glycidyl ether type epoxy resin 662 and diglycidyl endemethylene tetrahydrophthalate, and the amine curing agent adopts triethylenetetramine (TETA) and 3,3-dimethyl The compound of dimethyl-4,4-diaminodicyclohexylmethane (DMDC), the accelerator adopts 2-ethyl-4-methylimidazole (2E4MZ), the nanoparticle adopts carboxylated carbon tube, and the carbon fiber adopts Japan Toray The company's T800H-12K. The preparation process is as follows: adjust the ratio of ethylene glycol and carboxylated carbon tubes to 100:0.1, after mixing evenly, transfer to a hydrothermal reactor together with carbon fibers, the pressure is 1 MPa, and first react in a blast oven at 160 ° C for 4 hours, Then react in a blast oven at 100 ° C for 4 hours to obtain modified carbon fibers; add carboxylated carbon tubes to epox...

Embodiment 2

[0032] The mass fractions of epoxy resin, amine curing agent, accelerator and nanoparticles are prepared according to the ratio of 100:10:1:1. The epoxy resin adopts the compound of bis-resorcinol acetal tetraglycidyl ether, phthalate epoxy resin (731) and 4,4-diaminodiphenylmethane tetraglycidylamine, amine curing agent Polyetheramine D-400 was used, 2-ethyl-4-methylimidazole (2E4MZ) was used as the accelerator, aminated carbon nanotubes were used for the nanoparticles, and T800H-12K from Japan Toray Company was used as the carbon fiber. The preparation process is as follows: adjust the ratio of ethylene glycol and aminated carbon nanotubes to 100:3, after mixing evenly, transfer to a hydrothermal reactor together with carbon fibers, the pressure is 2MPa, and first react in a blast oven at 180 °C 7h, and then reacted in a blast oven at 120 °C for 5h to obtain modified carbon fibers; the aminated carbon nanotubes were added to the epoxy resin according to the proportion, and t...

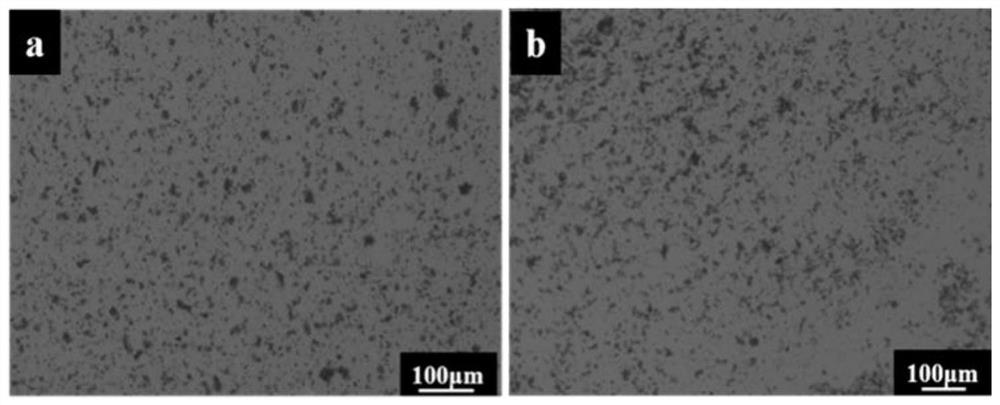

Embodiment 3

[0037] The mass fractions of epoxy resin, amine curing agent, accelerator and nanoparticles are prepared according to the ratio of 100:20:1.5:1. The epoxy resin adopts the compound of bis-resorcinol acetal tetraglycidyl ether and endomethylene tetrahydrophthalate diglycidyl ester, and the amine curing agent adopts 3,3-dimethyl-4,4 - Compound of diaminodicyclohexylmethane (DMDC) and polyetheramine D-400, 2-ethyl-4-methylimidazole (2E4MZ) is used as accelerator, silanized carbon nanotubes are used for nanoparticles, and carbon fibers are used T800H-12K from Toray Corporation of Japan. The preparation process is as follows: adjust the ratio of ethylene glycol and silanized carbon nanotubes to 100:0.5, after mixing evenly, transfer to a hydrothermal reactor together with carbon fibers, the pressure is 1.5MPa, and first react in a blast oven at 170 °C 5h, and then reacted in a blast oven at 110°C for 4h to obtain modified carbon fibers; silanized carbon nanotubes were added to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com