Rare earth alloy material and preparation method thereof

A technology of rare earth alloy and rare earth oxidation, which is applied in the field of rare earth alloy materials and its preparation, can solve the problems that the impact on the ecological environment cannot be ignored, the oxygen content of rare earth iron alloy is high, and the furnace temperature changes are difficult to control. It is easy to achieve the electrolysis process and increase the cathode Polarizing, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The raw materials of rare earth alloy materials are: rare earth oxide (the mass ratio of praseodymium oxide and neodymium oxide is 1:3), rare earth fluoride (the mass ratio of praseodymium fluoride and neodymium fluoride is 1:3) and the mass ratio of lithium fluoride is 100:4:0.5;

[0030] The preparation method of the above rare earth alloy material: (1) weighing each raw material according to the ratio of the rare earth alloy material, and mixing them to obtain the rare earth alloy material;

[0031] (2) Evenly add rare earth alloy materials into the electrolytic cell in batches, use metal tungsten as the cathode, and graphite as the anode, and control the current intensity, feed direct current for electrolysis, and complete the electrolysis at 1050 ° C for 43 minutes to obtain praseodymium neodymium metal; Among them, the DC voltage is 9V, and the cathode current density is 5.3A / cm 2 , control the anode current density to 2.0A / cm 2 .

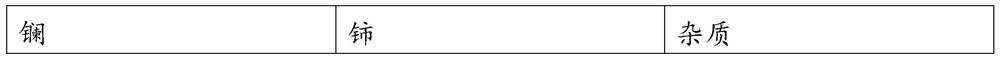

[0032] Table 1 Results analy...

Embodiment 2

[0035] The raw materials of rare earth alloy materials are: rare earth oxide (the mass ratio of lanthanum oxide and cerium oxide is 7:13), rare earth fluoride (the mass ratio of lanthanum fluoride and cerium fluoride is 7:13) and the mass ratio of lithium fluoride is 100:4:0.5;

[0036] The preparation method of the above rare earth alloy material: (1) weighing each raw material according to the ratio of the rare earth alloy material, and mixing them to obtain the rare earth alloy material;

[0037] (2) The rare earth alloy material is evenly added to the electrolytic cell in batches, using metal tungsten as the cathode and graphite as the anode, and controlling the current intensity, feeding direct current for electrolysis, and completing the electrolysis at 1050° C. for 43 minutes to obtain lanthanum cerium metal; Among them, the DC voltage is 10V, and the cathode current density is 0.6A / cm 2 , control the anode current density to 10A / cm 2 .

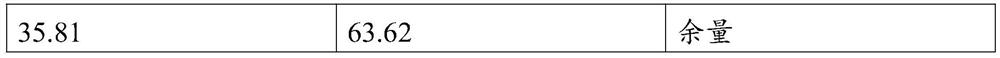

[0038] Table 2 The result an...

Embodiment 3

[0042] The raw material of the rare earth alloy material is: the mass ratio of rare earth oxide (europium oxide), rare earth fluoride (europium fluoride) and lithium fluoride is 100:4.5:0.6;

[0043] The preparation method of the above rare earth alloy material: (1) weighing each raw material according to the ratio of the rare earth alloy material, and mixing them to obtain the rare earth alloy material;

[0044] (2) Evenly add rare earth alloy materials into the electrolytic cell in batches, use metal tungsten as the cathode, and graphite as the anode, and control the current intensity, feed direct current for electrolysis, and complete the electrolysis at 1180° C. for 56 minutes to obtain europium metal; , DC voltage is 11V, cathode current density is 5.5A / cm 2, control the anode current density to 2.3A / cm 2 .

[0045] Table 3 The result analysis wt% of the alloy obtained in Example 3

[0046] europium Impurities 99.6 margin

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com