Method for reducing oil film oscillation harm

A technology of oil film oscillation and oil liquid, applied in the direction of lubricating oil input, engine lubrication, mechanical equipment, etc., can solve the problems of unidentified causes, failures, frequent accidents, unclear effective reasons, etc., and achieve simple measures Clear, targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

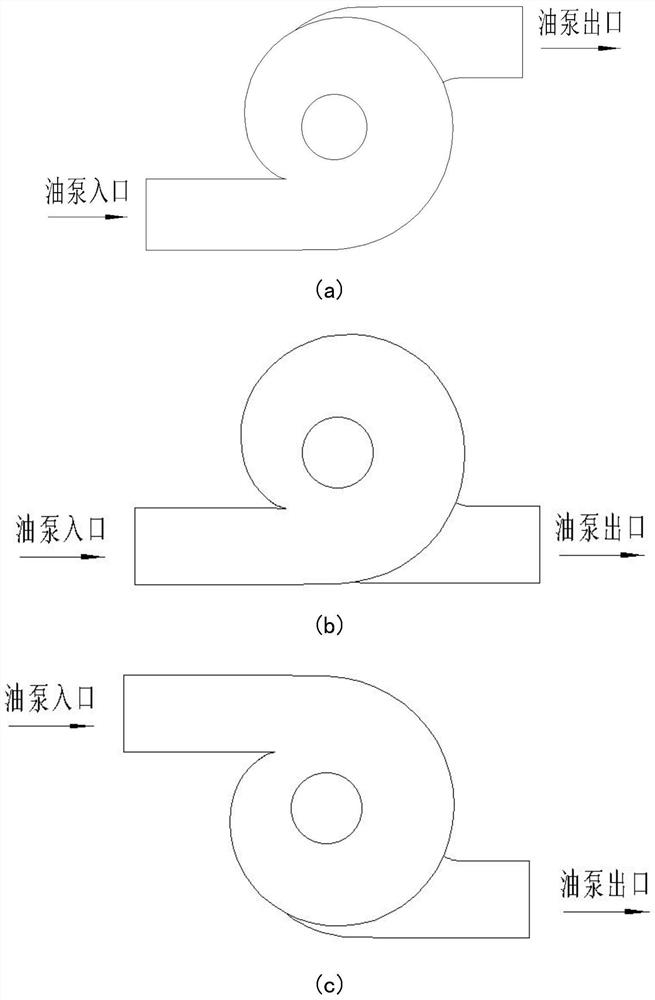

[0055] (1) if figure 2 As shown, the present invention selects figure 2 For the bottom-in, top-out lubricating oil supply pump shown in a, the air in the pump wheel and the pump casing can be automatically discharged before the pump is started, and it is rarely hidden in the oil pump. if choose figure 2 The bottom-in-bottom-out mode shown in b or figure 2 In the top-in and bottom-out mode shown in c, it is difficult to discharge the air accumulated in the pump body before starting up, and a large amount of air is mixed in the lubricating oil and sent to the bearing, creating conditions for the oil film to vibrate. It can be seen that the advantage of using the bottom-in and top-out lubricating oil supply pump is obvious.

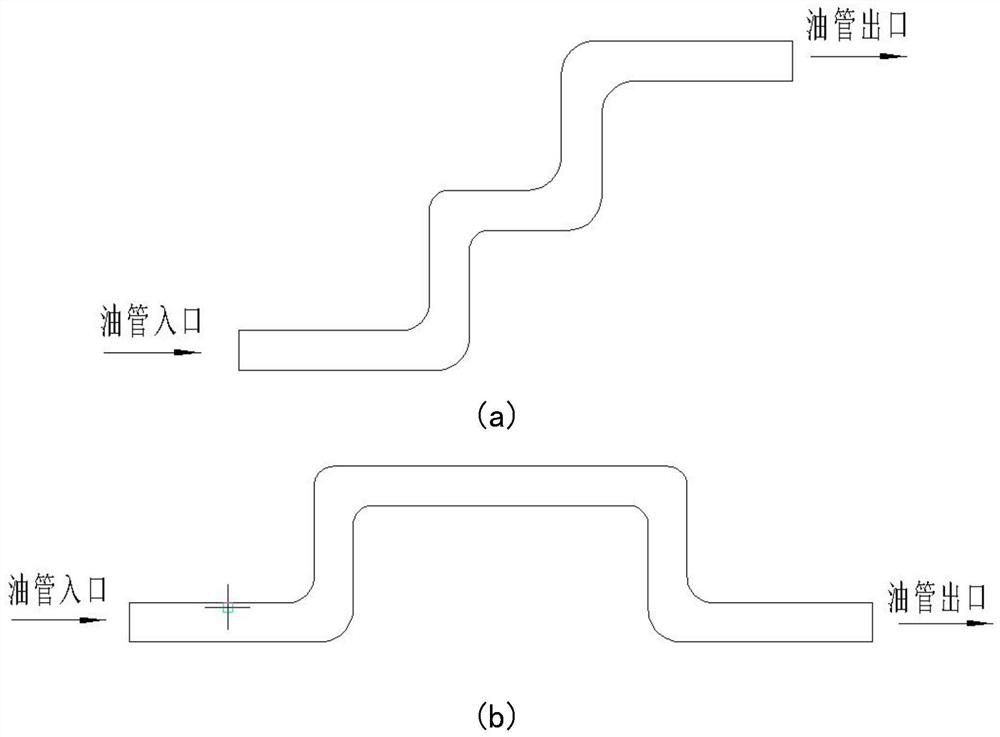

[0056] (2) if image 3 As shown, in the present invention, the oil supply pipeline system that only rises and does not fall is selected, and the pipeline outlet is set at the highest point of the pipeline system (such as image 3 shown in a), avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com