Flame stabilizer, radial flame stabilizer and combustion chamber

A flame stabilizer and stabilizer technology, applied in the field of turbo/ramjet combined engine and turbofan engine afterburner/ramjet combustor, which can solve the problem of increasing the thermal burden of fuel nozzles and flame stabilizers, increasing resistance loss, and preventing fuel from evaporating and igniting To achieve the effect of improving the atomization and evaporation performance, improving the ability of circumferential diffusion, and expanding the stable working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

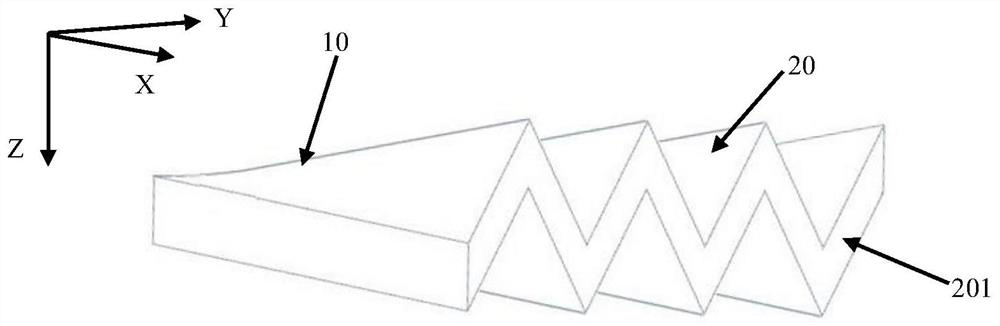

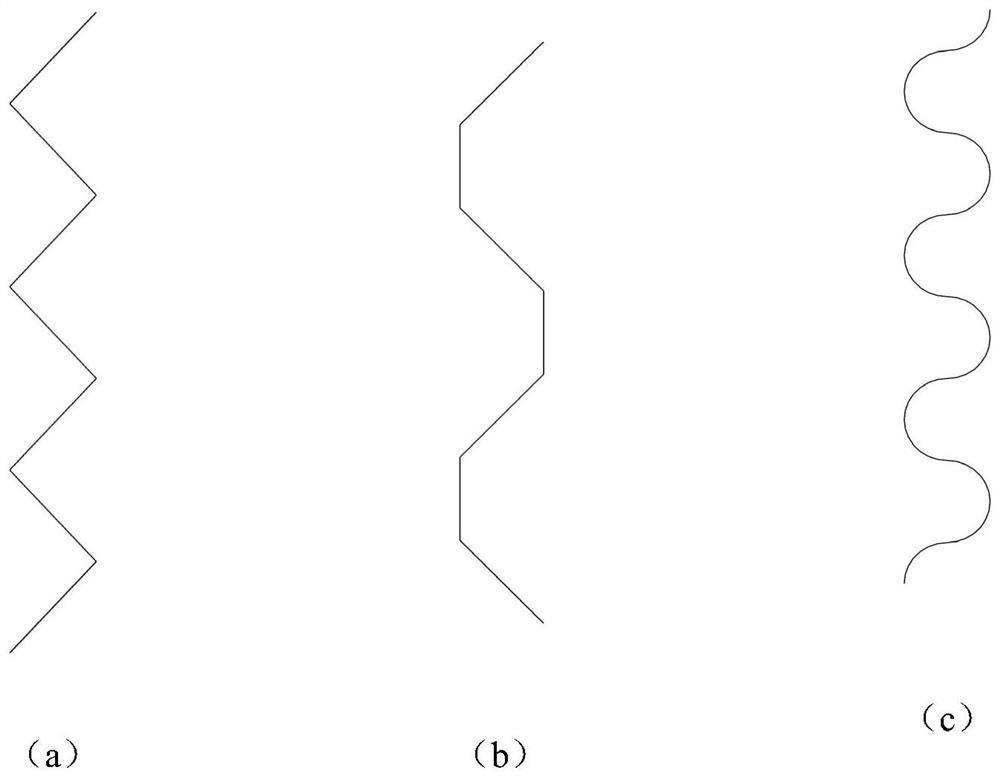

[0028] Embodiment 1: as figure 1 As shown, a flame stabilizer according to the present invention includes a stabilizer main body 10, and the stabilizer main body 10 has a periodic undulating surface 20, and the periodic undulating surface 20 includes several undulating units 201, and several undulating units 201 Arranged radially along the stabilizer main body 10 (the radial direction of the stabilizer main body 10 described in the present invention is figure 1 X-axis extension direction), each undulation unit 201 fluctuates toward the direction away from the stabilizer main body 10, and the far away from the stabilizer main body 10 described here is away from the plane direction where the stabilizer main body 10 is located, (stabilizer main body 10 on the plane with figure 1 The planes formed by the middle X axis-Y axis are parallel), and the wave directions of adjacent wave units 201 are opposite, and each wave unit 201 is from the front end to the rear end direction (the X...

Embodiment 2

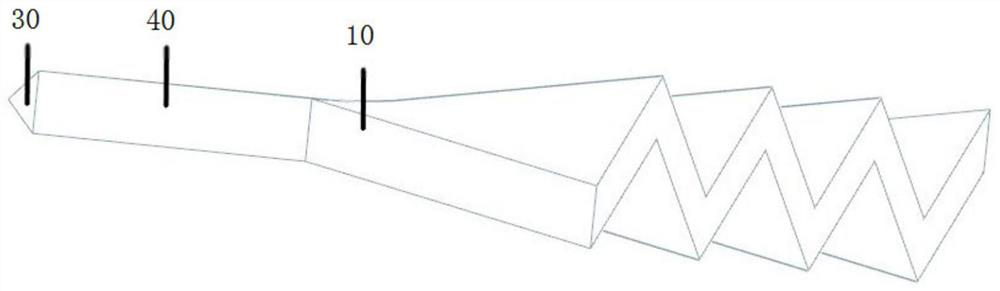

[0031] Embodiment 2: as Figure 3-5 As shown, utilizing the stabilizer main body 10 of embodiment 1, the present invention provides a radial flame stabilizer 1, comprising a leading edge section 30, a long straight section 40 arranged at the rear end of the leading edge section 30 and a long straight section arranged at the long straight section 40 rear end of the stabilizer main body 10 as described in Embodiment 1.

[0032] The leading edge section 30 in this embodiment is a V-shaped structure, along the direction from front to back, the distance between the two sides of the V-shaped structure gradually increases, and a hollow long straight section is provided at the tail end of the leading edge section 30 40. The long straight section 40 is roughly a hollow long cylinder, and the two sides of the long straight section 40 are provided with several oil injection holes 401. In an optional embodiment, the oil injection holes 401 are arranged along the radial direction on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com