Air source heat pump unit

An air source heat pump and unit technology, applied in the field of heat pumps, can solve problems such as underutilization of low-grade waste heat of flue gas, complex pipelines of the system, etc., and achieve the effect of avoiding unstable or incapable heating and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides an air source heat pump unit.

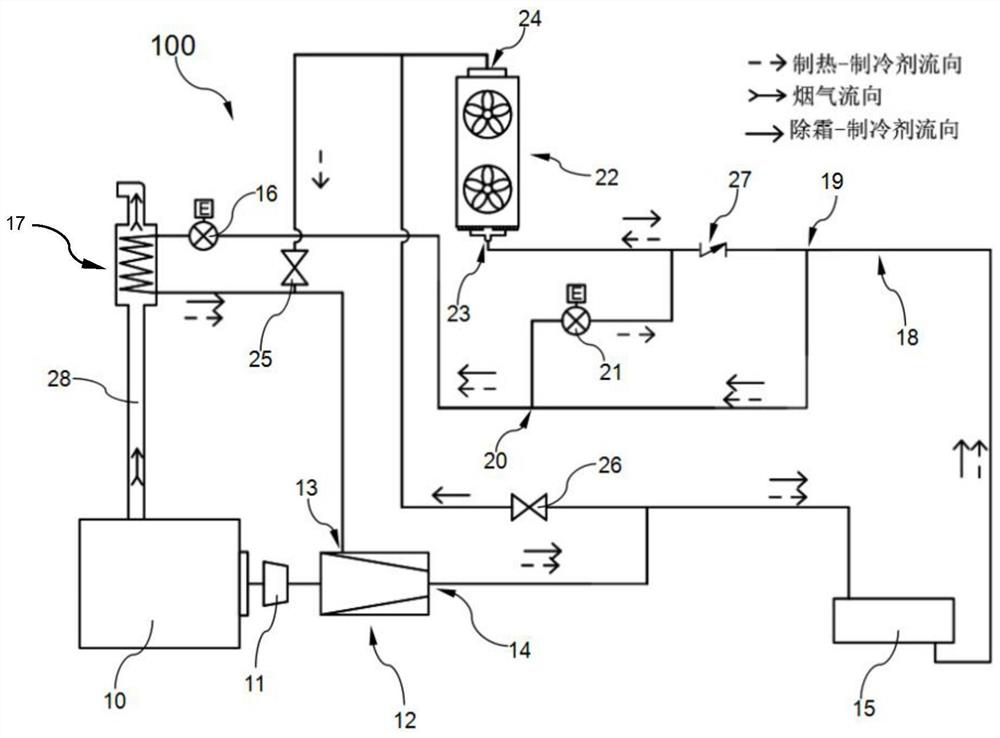

[0031] figure 1 It is a schematic diagram of the connection and flow of the air source heat pump unit in this embodiment.

[0032] Such as figure 1 As shown, the air source heat pump unit 100 includes a gas engine 10, a transmission device 11, a compressor 12, a first heat exchanger 15, a first throttle valve 16, a flue gas heat exchanger 17, a first pipeline 18, a second Throttle valve 21 , second heat exchanger 22 , first switching valve 25 , second switching valve 26 , and third switching valve 27 .

[0033] The output end of the gas engine 10 is connected together with the compressor 12 through the transmission device 11, and the compressor 12 is driven to compress the refrigerant gas inside it. The speed of the gas engine 10 is continuously adjustable, and the speed of the compressor 12 can be adjusted according to the needs of different operating conditions by adjusting the speed of the gas engine 10. Th...

Embodiment 2

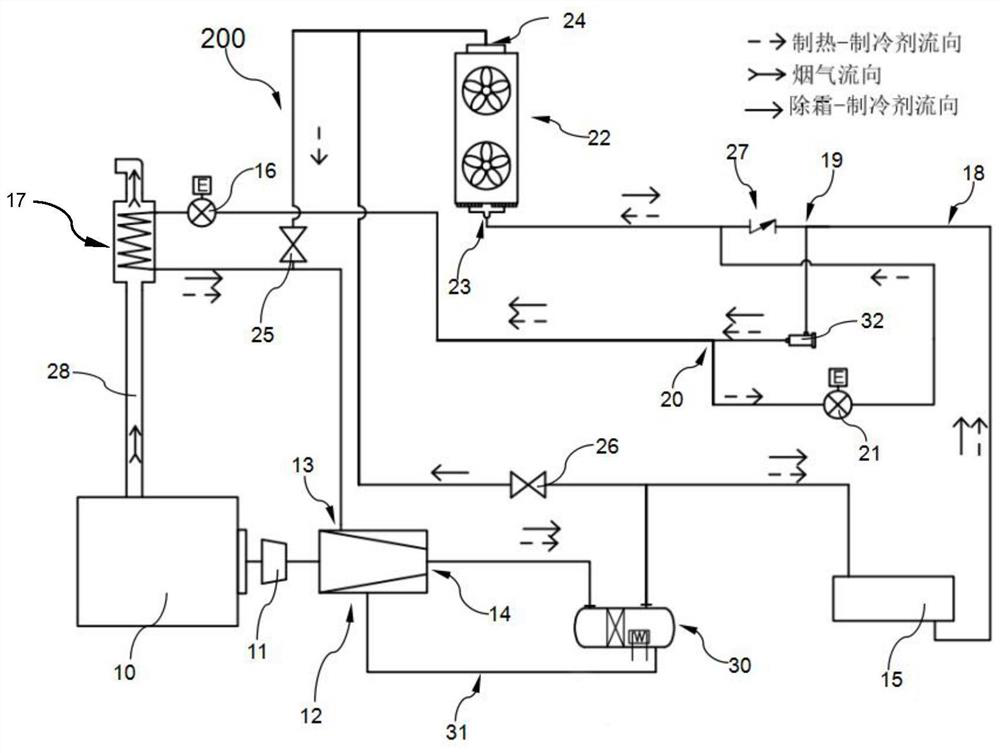

[0050] This embodiment provides an air source heat pump unit. The difference between the air source heat pump unit and the air source heat pump unit 100 in Embodiment 1 is that the air source heat pump unit 200 in this embodiment (see figure 2 ) also includes an oil separator 30, a lubricating oil circuit 31 and a filter drier 32. The first heat exchanger 15 of this embodiment does not include the oil separator 30 .

[0051] Other structures in this embodiment are the same as in Embodiment 1, and the same numbers are assigned to the same structures.

[0052] figure 2 It is a schematic diagram of the connection and flow of the air source heat pump unit 200 in this embodiment.

[0053] Such as figure 2 As shown, the oil separator 30 has an oil refrigerant inlet, an oil refrigerant outlet and a lubricating oil outlet, the oil refrigerant inlet is connected to the exhaust port 14, the oil refrigerant outlet is connected to the first refrigerant inlet, and the lubricating oil...

Embodiment 3

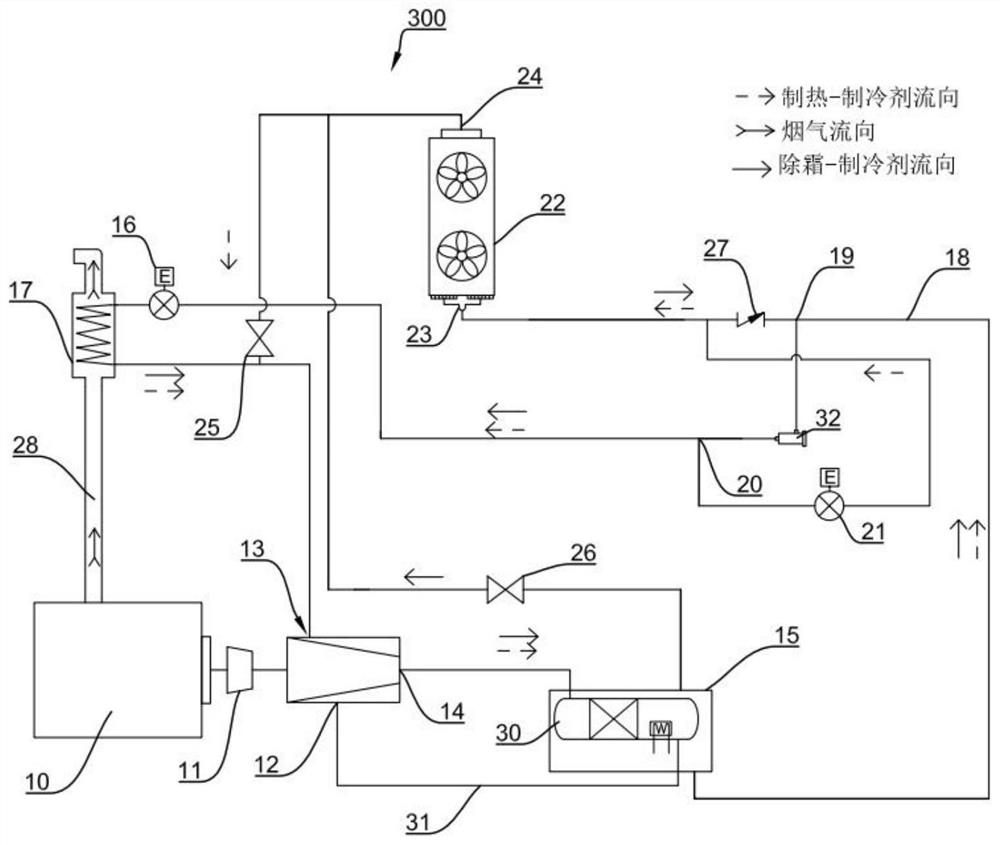

[0063] This embodiment provides an air source heat pump unit. The difference between the air source heat pump unit and the air source heat pump unit 200 in Embodiment 2 is that the first heat exchanger 15 of the air source heat pump unit 300 in this embodiment includes Oil separator 30. Other structures in this embodiment are the same as in Embodiment 1, and the same numbers are given to the same structures.

[0064] image 3 It is a schematic diagram of the connection and flow of the air source heat pump unit in the third embodiment.

[0065] Such as image 3 As shown, the oil separator 30 is arranged in the first heat exchanger 15, and has an oil component refrigerant inlet, an oil component refrigerant outlet and a lubricating oil discharge port. The refrigerant gas containing lubricating oil is discharged from the exhaust port 14 of the compressor 12, enters the first refrigerant inlet, and then enters the oil separator 30 through the oil-separated refrigerant inlet, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com