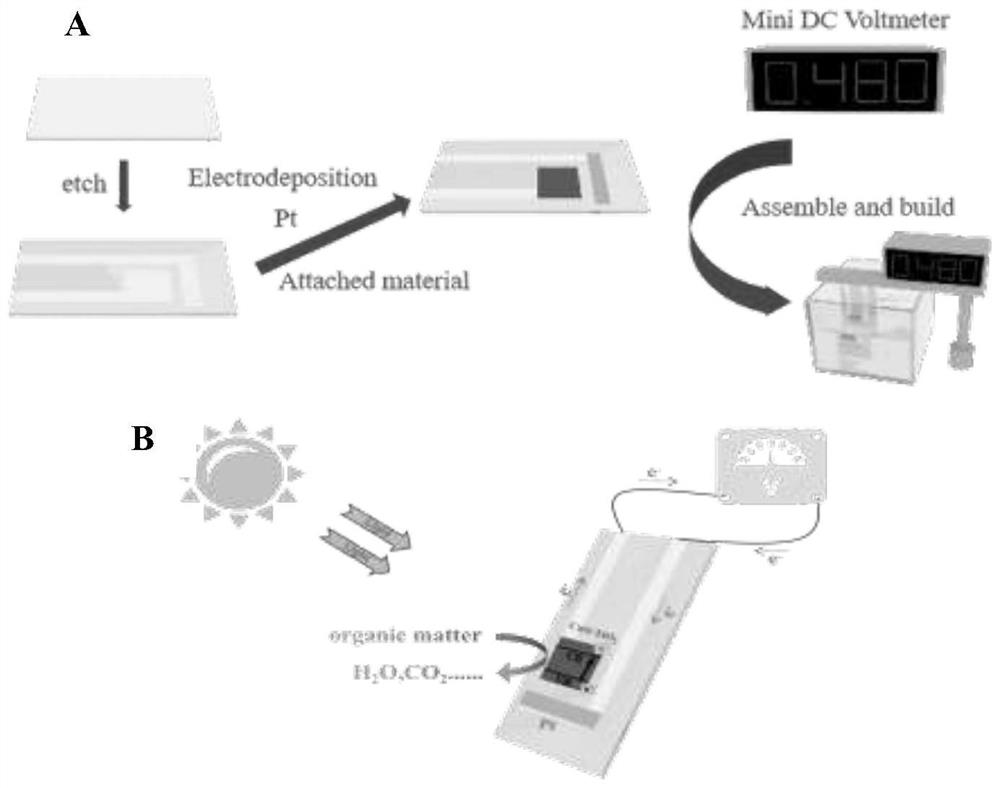

Construction method of portable potentiometric photoelectrochemical sensor for quickly detecting chemical oxygen demand

A chemical oxygen demand and construction method technology, which is applied in the field of rapid detection of chemical oxygen demand portable potentiometric photoelectrochemical sensors, can solve the problems of highly corrosive sulfuric acid, environmental secondary pollution, poisonous and harmful, etc., and achieve improved degradation Efficiency, cost reduction, and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

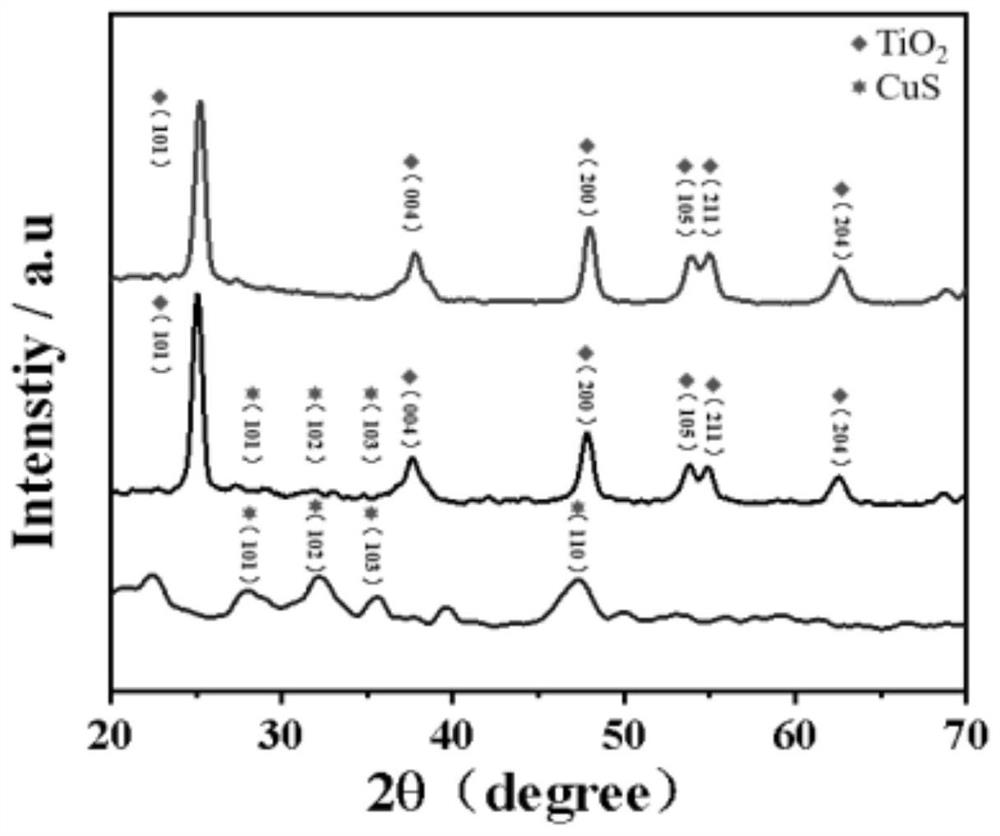

[0044] (1) Synthesis of TiO 2 / CuS nanosheets

[0045] Weigh 0.4g of purchased P25 TiO 2 The powder was added into a mixed solvent of 10mL of water and 30mL of ethylene glycol, and ultrasonically treated for 30min to form a uniform dispersion. Then add 2mmol CuCl to the above solvent 2 2H 2 O and 2 mmol Na 2 S 2 o 3 ·5H 2 O, the solution is stirred until the color of the solution turns yellow-green, the yellow-green solution is poured into a 100m L round bottom flask, the temperature of the oil bath is heated to 70°C, and the round bottom flask is placed in the oil bath , Stirring and heating continuously for 4h. Finally, the flask was taken out from the oil bath, cooled naturally at room temperature, the resulting solution was centrifuged at 7000 rad / s for 10 min, washed with ethanol and water three times, and dried at 60°C for 4 h.

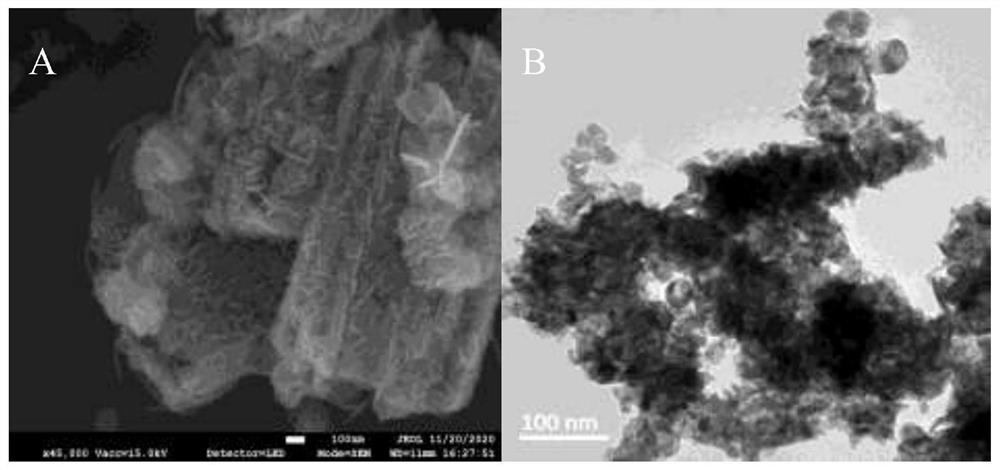

[0046] figure 2 It is the TiO obtained in Example 1 2 SEM and TEM images of / CuS, nano-TiO can be seen 2 Attached to the surface o...

Embodiment 2

[0060] (1) Synthesis of TiO 2 / CuS nanosheets

[0061] Weigh 0.3g of purchased P25 TiO 2 The powder was added into a mixed solvent of 10mL of water and 30mL of ethylene glycol, and ultrasonically treated for 30min to form a uniform dispersion. Then add 2mmol CuCl to the above solvent 2 2H 2 O and 2 mmol Na 2 S 2 o 3 ·5H 2 O, the solution is stirred until the color of the solution turns yellow-green, the yellow-green solution is poured into a 100m L round bottom flask, the temperature of the oil bath is heated to 70°C, and the round bottom flask is placed in the oil bath , Stirring and heating continuously for 4h. Finally, the flask was taken out from the oil bath, cooled naturally at room temperature, the resulting solution was centrifuged at 7000 rad / s for 10 min, washed with ethanol and water three times, and dried at 60°C for 4 h.

[0062] Step (2), (3) and (4) are the same as step (2), (3) and (4) of embodiment 1.

Embodiment 3

[0064] (1) Synthesis of TiO 2 / CuS nanosheets

[0065] Weigh 0.5g of purchased P25 TiO 2 The powder was added into a mixed solvent of 10mL of water and 30mL of ethylene glycol, and ultrasonically treated for 30min to form a uniform dispersion. Then add 2mmol CuCl to the above solvent 2 2H 2 O and 2 mmol Na 2 S 2 o 3 ·5H 2 O, the solution is stirred until the color of the solution turns yellow-green, the yellow-green solution is poured into a 100m L round bottom flask, the temperature of the oil bath is heated to 70°C, and the round bottom flask is placed in the oil bath , Stirring and heating continuously for 4h. Finally, the flask was taken out from the oil bath, cooled naturally at room temperature, the resulting solution was centrifuged at 7000 rad / s for 10 min, washed with ethanol and water three times, and dried at 60°C for 4 h.

[0066] Step (2), (3) and (4) are the same as step (2), (3) and (4) of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com