Preparation method of nitrogen-doped porous carbon-coated hollow cobalt-nickel alloy composite wave absorbing material

A nitrogen-doped porous carbon and composite wave absorbing material technology, applied in the field of wave absorbing materials, can solve the problems of complex preparation method, high cost and high equipment requirements, and achieve the effects of simple preparation process, low production cost and stable material performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

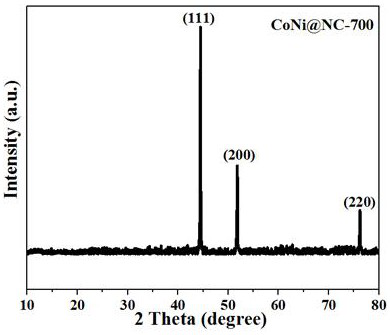

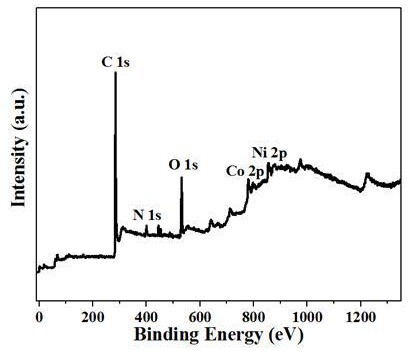

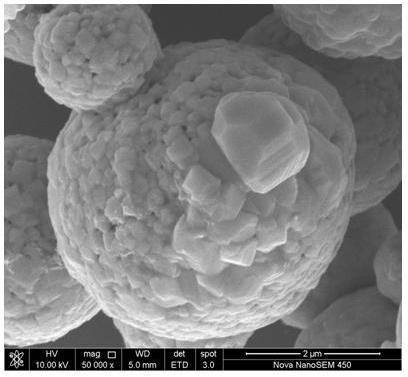

[0022] Using CoNi@PDA as a template, the method for preparing CoNi@NC composite absorbing material is as follows:

[0023] Step 1: Add 0.48g of CoCl 2 ·6H 2 O, 0.48g of NiCl 2 ·6H 2 O and 1 g of polyvinylpyrrolidone (PVP) were dissolved together in 36 mL of ethylene glycol, stirring was continued for 30 min, and then 6 mL of 60% hydrazine hydrate solution was sequentially dropped into the above solution under strong stirring and stirred for 20 min. The resulting suspension was transferred to a tetrafluoroethylene-lined stainless steel reactor and kept in an air oven at 180° C. for 6 h. After the reaction, the obtained products were collected and washed with deionized water and ethanol at least three times respectively to remove residual impurities; finally, they were placed in a vacuum oven and dried under vacuum at 60 °C for 8 h to obtain hollow CoNi alloy microstructures. ball.

[0024] Step 2: Disperse 0.2 g of CoNi alloy microspheres and 0.24 g of dopamine hydrochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com