Intelligent livestock farm sewage ecological cycle purification treatment system and process

A technology of purification treatment and ecological cycle, applied in biological water/sewage treatment, water/sludge/sewage treatment, animal husbandry wastewater treatment, etc., can solve the problems of secondary pollution, high operating cost, high hardware input cost, etc., to achieve Strong adaptability and the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

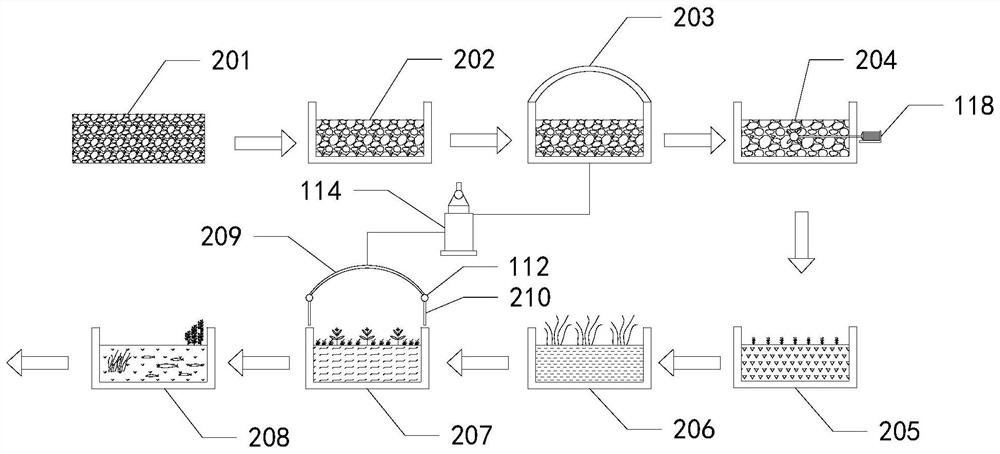

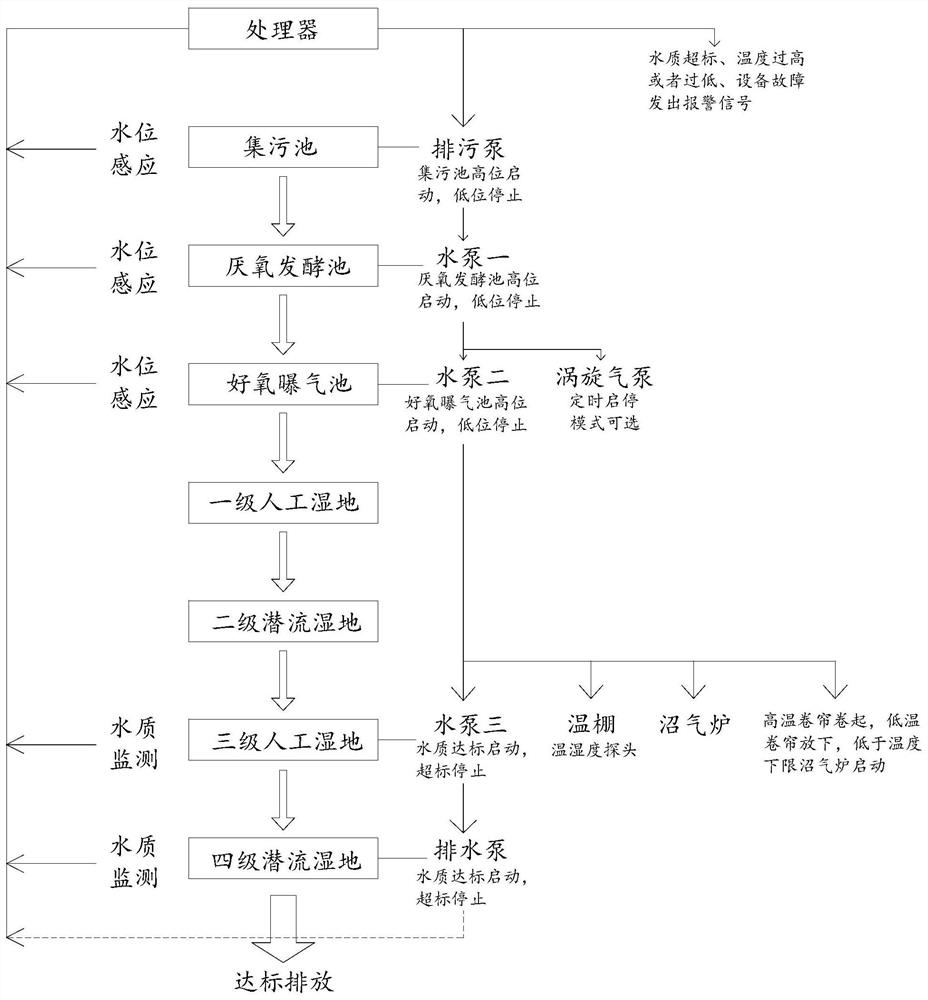

[0075] Specific examples: pig farms, 2000 live pigs in stock, sewage production 8kG / day / head, produce sewage 8*2000=16 tons / day every day, domestic sewage 4 tons / day, total production sewage 20 tons / day.

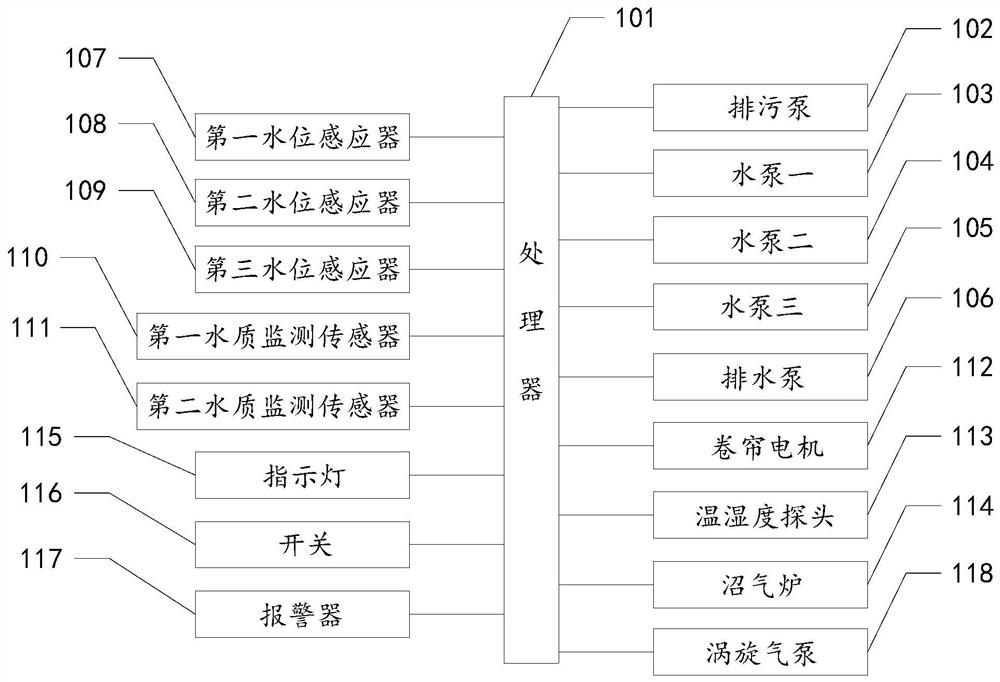

[0076] Sewage collection tank 3600m 3 ; Anaerobic fermentation tank 900m 3 ;Aerobic aeration tank 300m 3 ; The first-class artificial wetland area is 6000m 2 ; The area of secondary subsurface flow wetland is 600m 2 ; The third-level (surface flow) wetland area is 14500m 2 ; The fourth-grade subsurface flow wetland covers an area of 400m 2 ;In addition, it is equipped with an intelligent monitoring and control device, using ARM embedded development STM8s103 processor, and the water quality monitoring sensor adopts AMT-FB301 online small COD sensor probe, which is installed at the outlet of the third-level artificial wetland and the fourth-level subsurface flow wetland respectively. The temperature and humidity probe adopts HMP110 temperature and humidity probe, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com