3D-printed short implant with gradient and porous outer layer and preparation method for 3D-printed short implant

A 3D printing, gradient porous technology, applied in the direction of prosthesis, dental implants, manufacturing auxiliary devices, etc., can solve the problems of stress shielding effect, small osseointegration area, and inability to support denture functions for a long time, so as to reduce stress concentration and increase The osseointegration area is conducive to the effect of tight integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

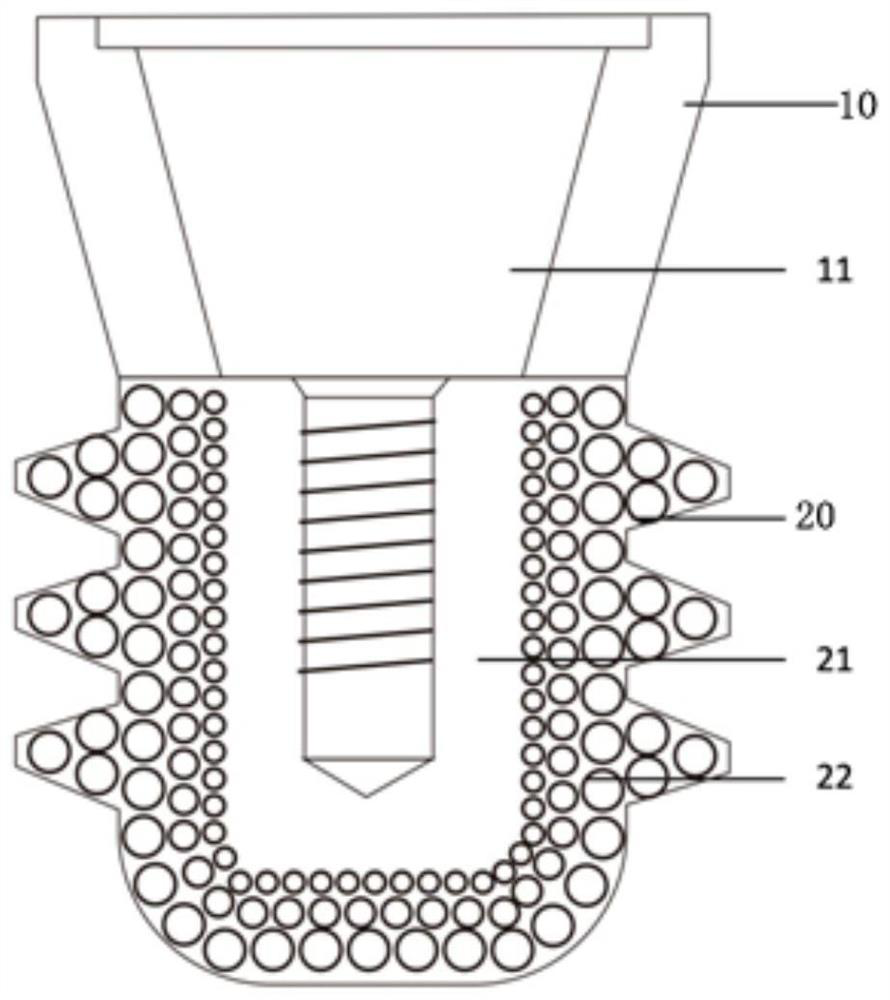

[0024] figure 1 It is a schematic structural diagram of the 3D printed outer gradient porous short implant of the present invention. like figure 1 As shown, the short implant is used to be implanted into the patient's alveolar bone implant socket, comprising: a head 10 and a body 20 connected to the bottom surface of the head 10; the head 10 is a gingival part, and the body 20 is an osseointegration part. The body part 20 comprises: a dense core body 21 and a porous layer 22 arranged outside the dense core body 21; the porous layer 22 has pores; from the dense core body 21 to the direction of the alveolar bone, the porosity of the porous layer 22 gradually increases, and its The elastic modulus gradually decreases from being close to or equal to the dense core 21; and, the average elastic modulus of the porous layer as a whole is the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com