Sulfamic acid production equipment and sulfamic acid synthesis process

A technology of sulfamic acid and production equipment, which is applied in the field of sulfamic acid preparation and can solve problems such as uneven urea blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

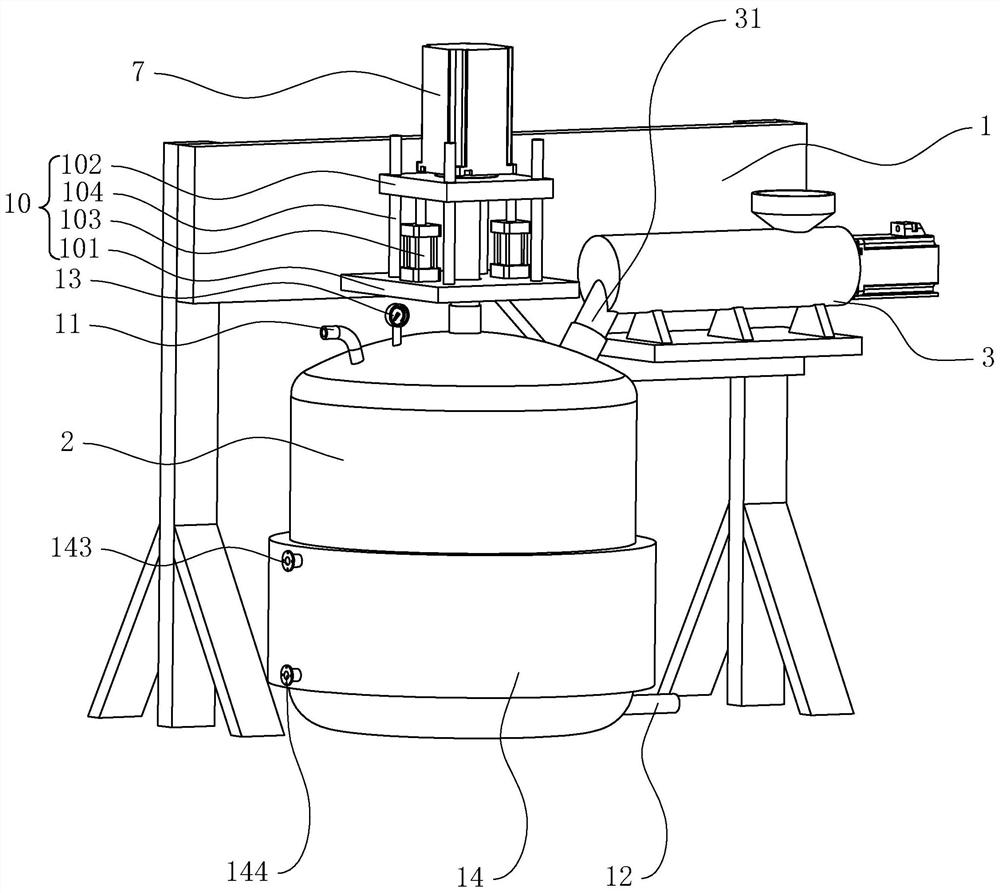

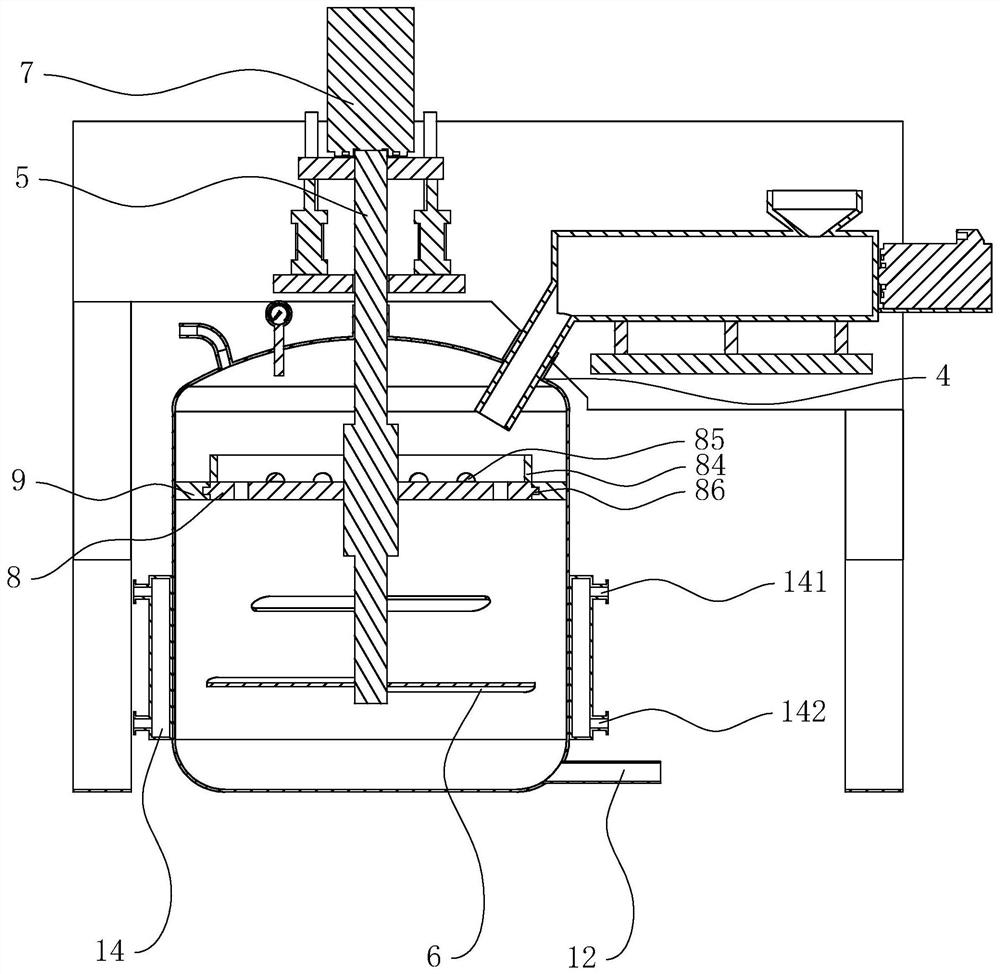

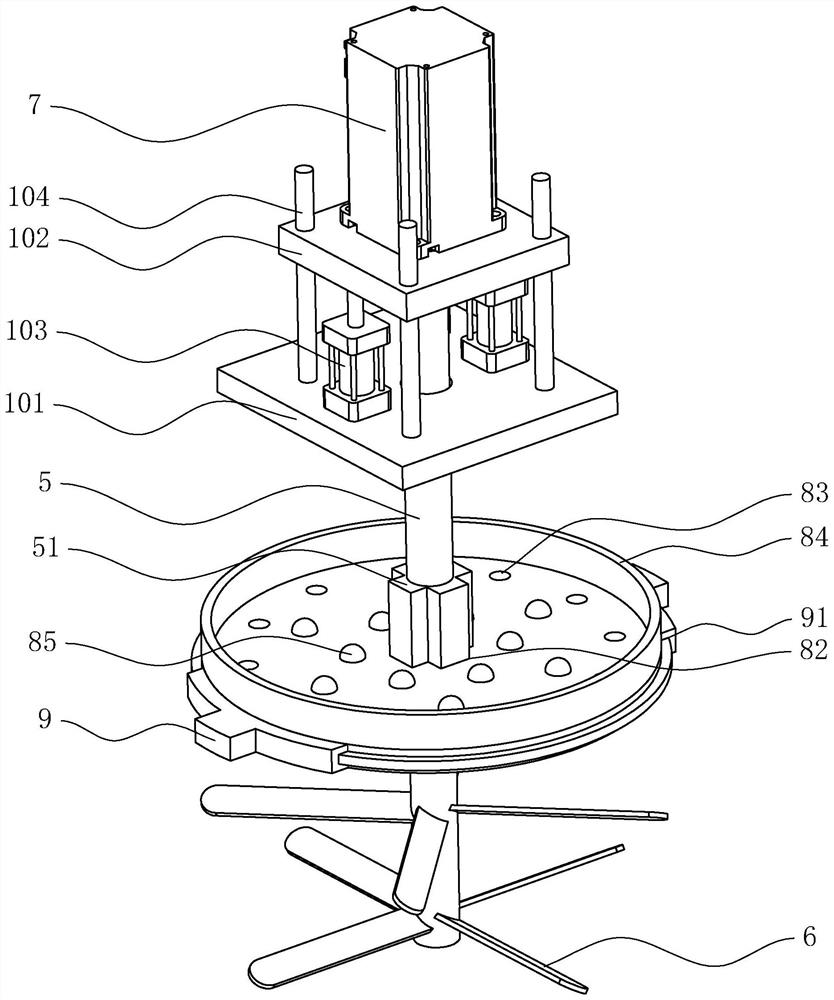

[0044] refer to figure 1 and figure 2 , a kind of sulfamic acid production equipment comprises frame 1, and the bottom of frame 1 is placed with reactor 2, and one side of reactor 2 is provided with screw feeder 3, and screw feeder 3 is fixedly connected on the frame 1 One end of the screw feeder 3 is fixedly connected with a feed pipe 31 , the top of the reaction kettle 2 is provided with a feed port 4 , and the feed pipe 31 is plugged into the feed port 4 .

[0045] refer to figure 1 and figure 2 , the reactor 2 is fixedly connected with an exhaust pipe 11 for discharging waste gas, the bottom of the reactor 2 is fixedly connected with a discharge pipe 12 for discharging reactants, and the reactor 2 is provided with a temperature probe 13 for detecting the reaction temperature .

[0046] refer to figure 1 and figure 2 , the reactor 2 is covered with a jacket 14 for temperature control, the inner wall of the jacket 14 is fixedly connected with the outer wall of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com