A small high-temperature aerobic composting device for high-viscosity materials

An aerobic composting, high-viscosity technology, applied in fertilization devices, organic fertilizers, preparation of organic fertilizers, etc., can solve problems such as anaerobic and water imbalance, reduce heat loss, reduce heat loss, and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

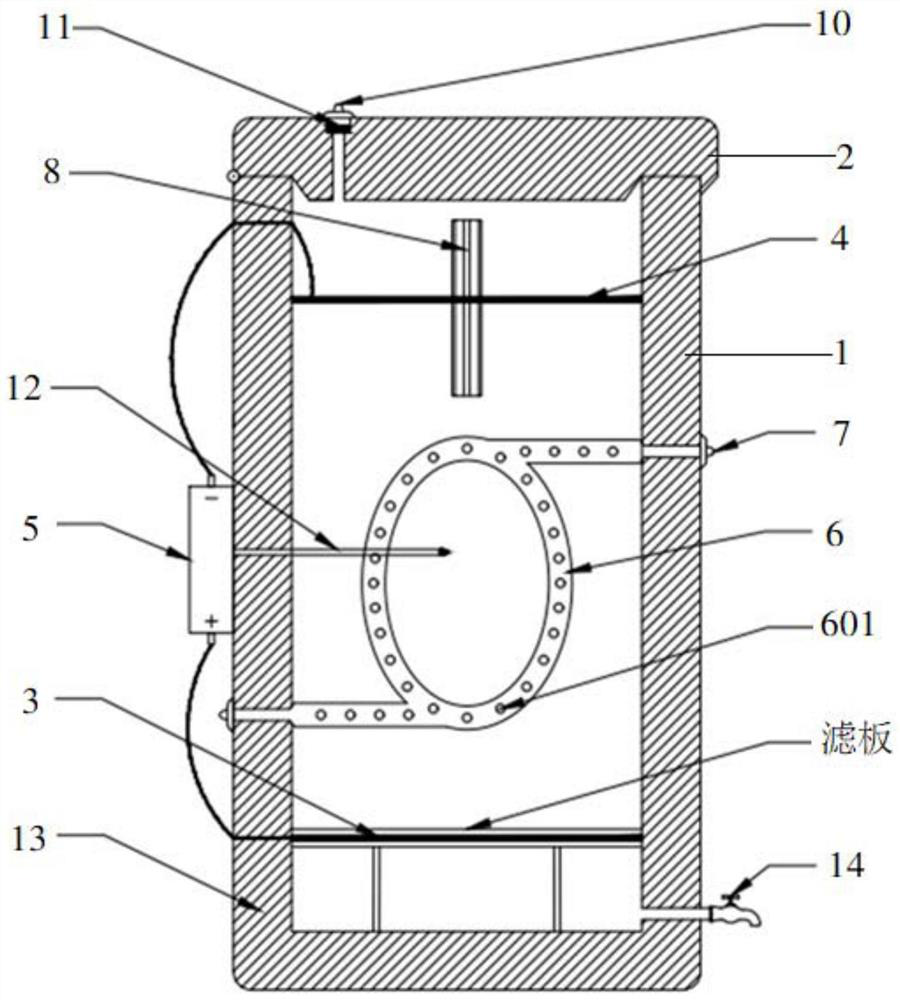

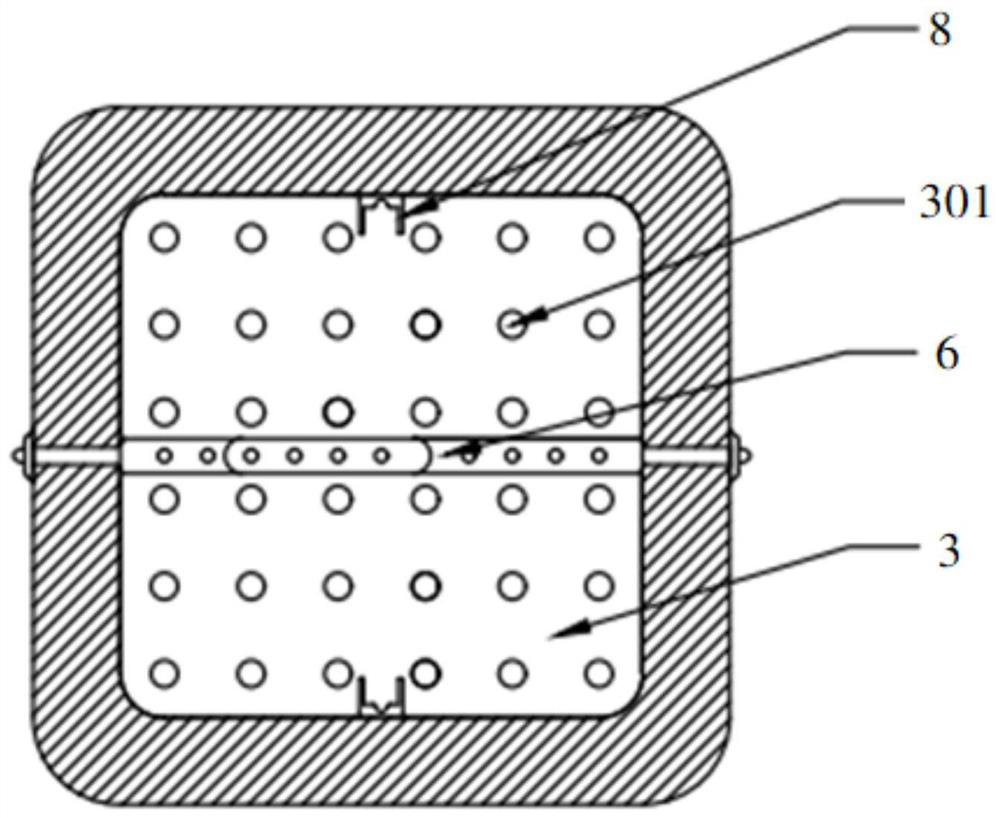

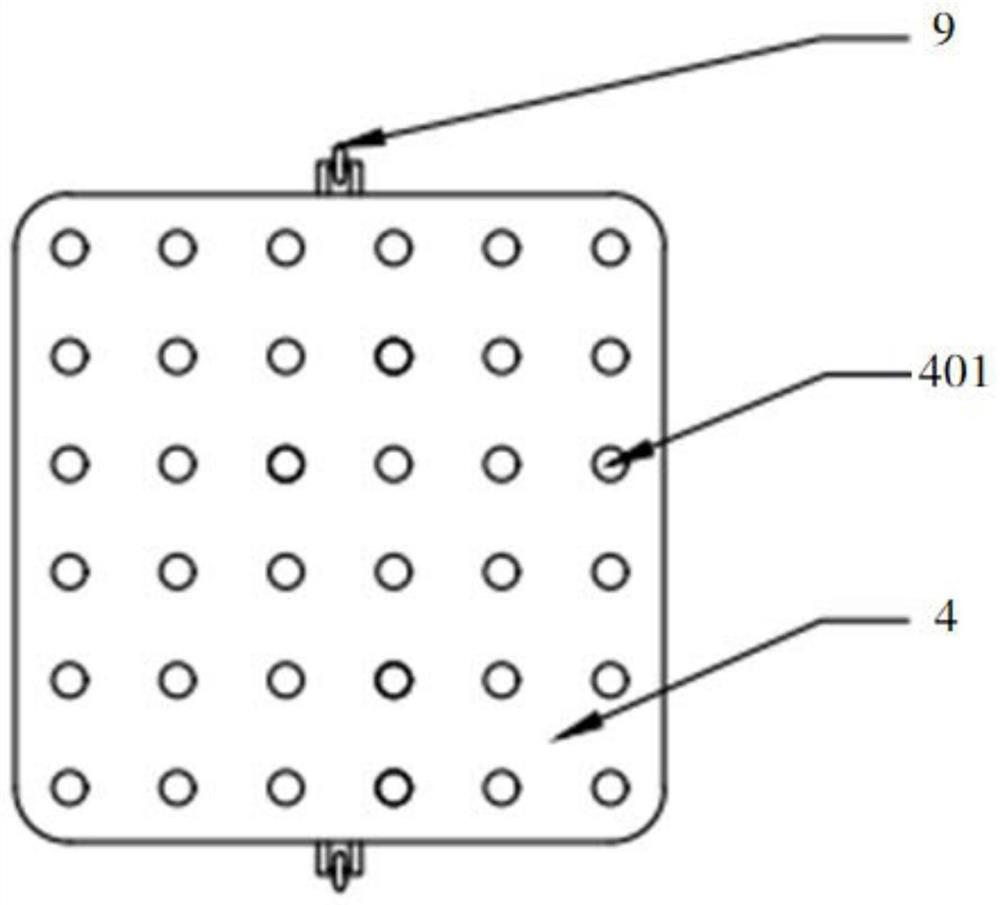

[0034] Such as figure 1 , 2 , 3. A small high-temperature aerobic composting device for high-viscosity materials, including a shell 1 and a cover 2 for filling compost materials. The lower part of the shell 1 is fixed with an anode plate 3 that also serves as a filter plate. A cathode plate 4 is movable, and the anode plate 3 and the cathode plate 4 are respectively connected to the positive pole and the negative pole of the DC power supply 5 , and the ventilation pipe 6 capable of introducing oxygen is provided between the anode plate 3 and the cathode plate 4 in the housing 1 .

[0035] The upper and lower parts of the housing 1 are respectively provided with a ventilation valve 7 which can adjust the ventilation volume. Natural circulation improves ventilation efficiency. Vent pipe 6 is vertically arranged in the middle of housing 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com