Method for purifying polyethylene glycol monomethyl ether monophosphate/diphosphate

A polyethylene glycol monomethyl ether and purification method technology, which is applied in the field of biomedicine, can solve problems such as difficulty in large-scale production, and achieve the effect of being easy to obtain and meeting the market's large-volume demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

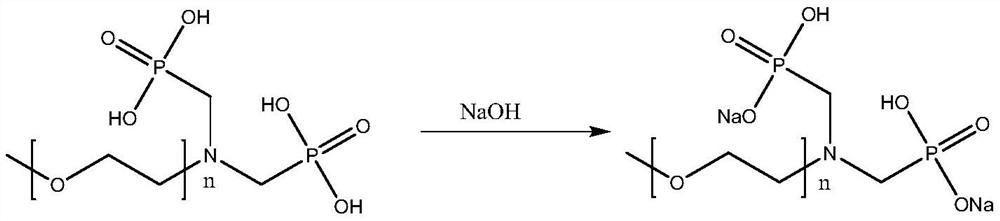

Image

Examples

Embodiment 1

[0020] Self-made polyethylene glycol monomethyl diphosphate 2.0g (purity HPLC: 93.7%), add 10ml of purified water to dissolve, adjust to alkaline with 10% NaOH aqueous solution, T=20~30℃, stir for 5min, the pH value is not Change again, add MeOH, THF, and DCM while stirring, stir at room temperature for 10 min, and let stand to separate layers. Separate the organic phase for waste liquid treatment, the water phase is the product, concentrate the water phase to dryness with a rotary evaporator, add MTBE, stir and crystallize for 30 minutes, filter to obtain the product solid, dry 1.63g, yield 77%, purity HPLC: 99.52% .

Embodiment 2

[0022] Self-made polyethylene glycol monomethyl diphosphate 2.0g (purity HPLC: 93.7%), add 10ml of purified water to dissolve, adjust to alkaline with 10% NaOH aqueous solution, T=20~30℃, stir for 5min, the pH value is not Change again, add methanol, dichloromethane and acetonitrile under stirring state, stir for 10 min, and let stand to separate layers. The organic phase was separated and treated as waste liquid, the aqueous phase was the product, the solvent was concentrated to dryness by a rotary evaporator, MTBE was added to stir and crystallize for 30 minutes, the product solid was obtained by filtration, and dried 1.67g, the yield was 79%, and the purity by HPLC: 99.67%.

Embodiment 3

[0024] Self-made polyethylene glycol monomethyl diphosphate 2.0g (purity HPLC: 93.7%), add 10ml of purified water to dissolve, adjust to alkaline with 10% NaOH aqueous solution, T=20~30℃, stir for 5min, the pH value is not Change again, add 2-methyltetrahydrofuran, dichloromethane and methanol mixed solvent under stirring state, stir for 10 min, and let stand to separate layers. Separate the organic phase for waste treatment, the water phase is the product, concentrate the solvent to dryness with a rotary evaporator, add 20ml of MTBE, stir and crystallize for 30min, filter to obtain the product solid, dry 1.71g, yield 81%, purity HPLC: 99.09% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com