Threaded hole protection glue and preparation method and application thereof

A technology of protective glue and threaded holes, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., and can solve problems such as difficult peeling and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

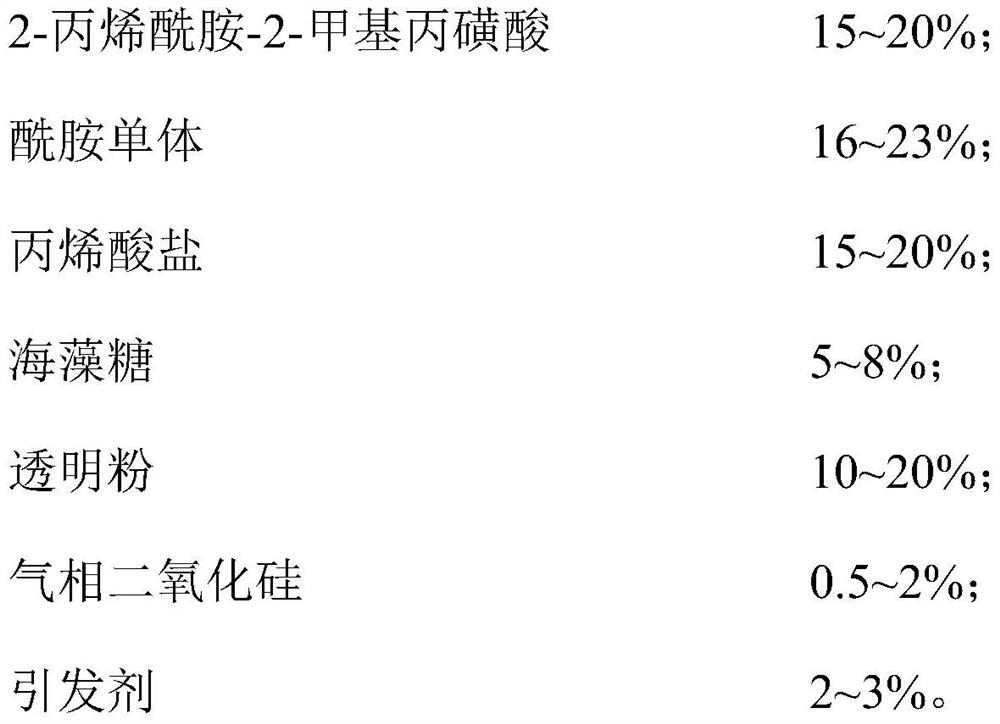

[0070] This embodiment provides a threaded hole protective glue and a preparation method thereof. The threaded hole protective glue includes the following components in mass percentage:

[0071]

[0072] The particle size of the aminopropyltriethoxysilane modified transparent powder is 1000 mesh.

[0073] The preparation method of the above threaded hole protective glue is as follows:

[0074] (1) Stir 2-acrylamide-2-methylpropanesulfonic acid, trehalose, and water at 25°C until uniform and transparent, then add carboxy-modified guar gum and continue stirring until evenly mixed to obtain mixture A ;

[0075] (2) Stir the mixture A obtained in step (1), fumed silica and aminopropyltriethoxysilane modified transparent powder at 35°C for 25 minutes to obtain mixture B;

[0076] (3) Stir the mixture B, acrylamide and sodium acrylate obtained in step (2) for 45 min at 25°C to obtain mixture C;

[0077] (4) Stir the mixture C obtained in step (3) with bis(2,4,6-trimethylbenzoy...

Embodiment 2

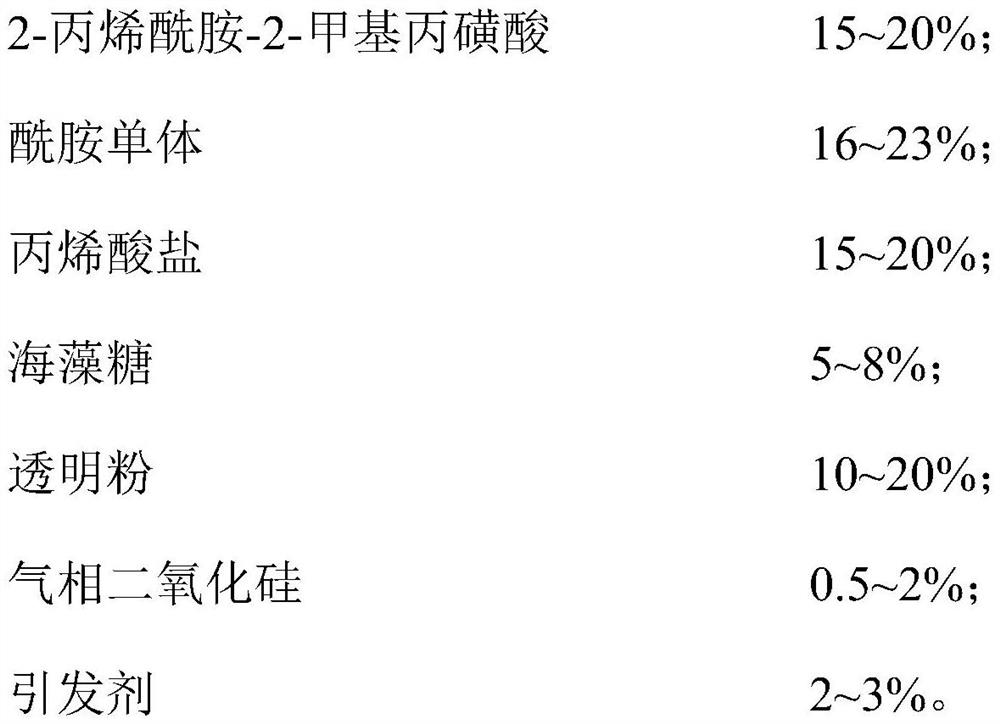

[0079] This embodiment provides a threaded hole protective glue and a preparation method thereof. The threaded hole protective glue includes the following components in mass percentage:

[0080]

[0081] The particle size of the aminopropyltriethoxysilane modified transparent powder is 1000 mesh.

[0082] The preparation method of the above threaded hole protective glue is as follows:

[0083] (1) Stir 2-acrylamide-2-methylpropanesulfonic acid, trehalose and water at 20°C until uniform and transparent, then add quaternary ammonium salt-modified guar gum, and continue stirring until the mixture is uniform. Mixture A is obtained;

[0084] (2) Stir the mixture A obtained in step (1), fumed silica and aminopropyltriethoxysilane modified transparent powder at 50°C for 15 minutes to obtain mixture B;

[0085] (3) Stir the mixture B, methacrylamide and potassium acrylate obtained in step (2) for 20 min at 40° C. to obtain mixture C;

[0086] (4) Under the condition of 40°C, sti...

Embodiment 3

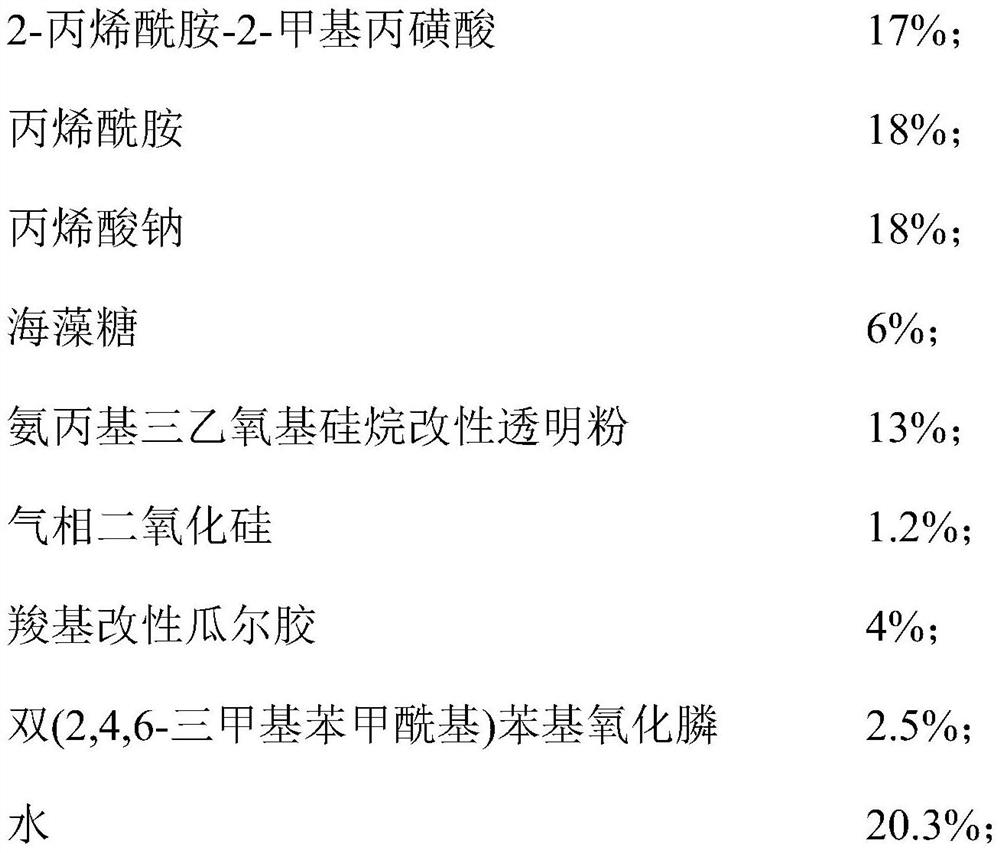

[0088] This embodiment provides a threaded hole protective glue and a preparation method thereof. The threaded hole protective glue includes the following components in mass percentage:

[0089]

[0090] The initiator is composed of 2-hydroxy-4'-(2-hydroxyethoxy)-2-methyl propiophenone and two (2,4,6-trimethylbenzoyl) phenylphosphine oxide in mass ratio 1:1 composition, the particle size of the aminopropyltriethoxysilane modified transparent powder is 1200 mesh.

[0091] The preparation method of the above threaded hole protective glue is as follows:

[0092] (1) Under the condition of 30°C, stir 2-acrylamide-2-methylpropanesulfonic acid, trehalose and water until uniform and transparent, then add quaternary ammonium salt modified squash gum and continue stirring until uniformly mixed to obtain mixture A;

[0093] (2) Stir the mixture A obtained in step (1), fumed silica and aminopropyltriethoxysilane modified transparent powder at 40°C for 20 minutes to obtain mixture B;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com