Method for preparing monocrystal two-dimensional transition metal chalcogenide

A transition metal chalcogenide and transition metal technology, which is applied in the field of preparing single crystal two-dimensional transition metal chalcogenide compounds, can solve problems such as existence of grain boundaries and no orientation, and achieve the effects of low cost, few defects and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

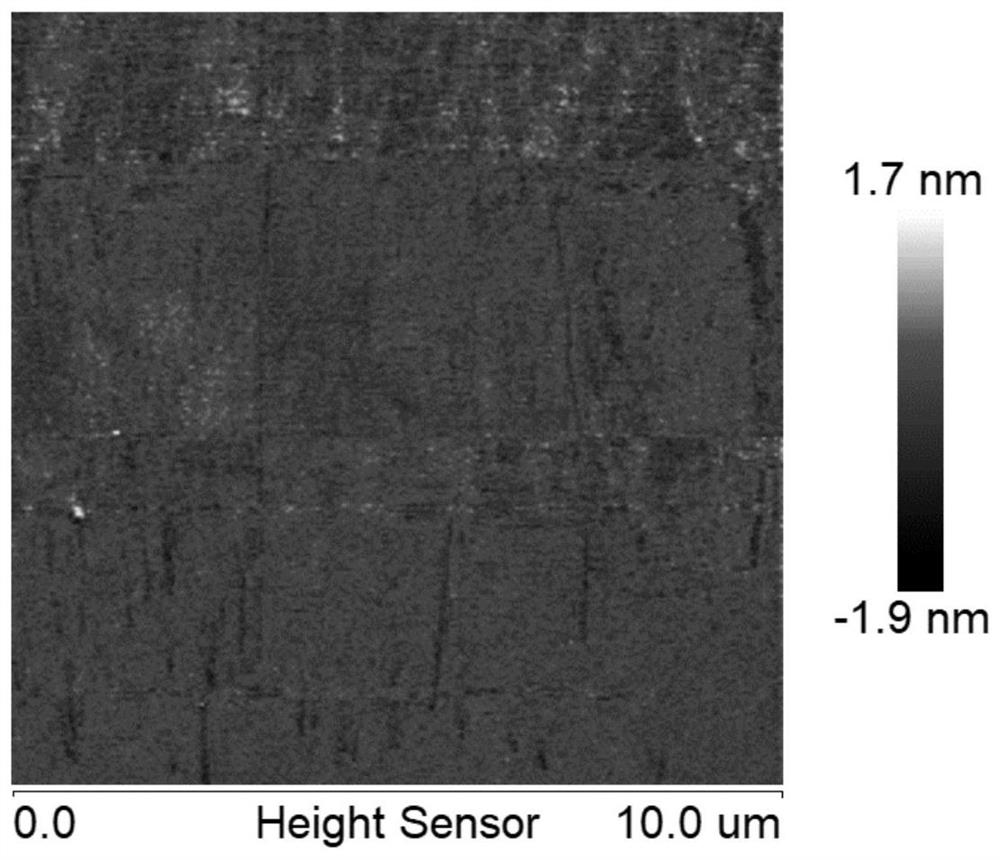

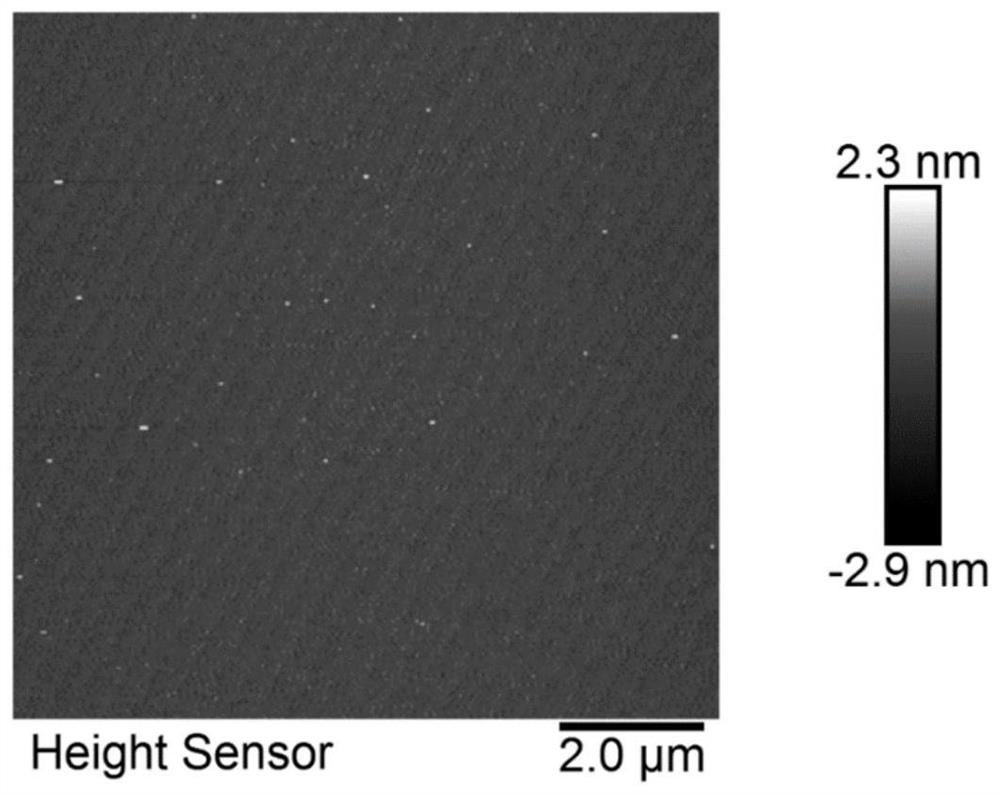

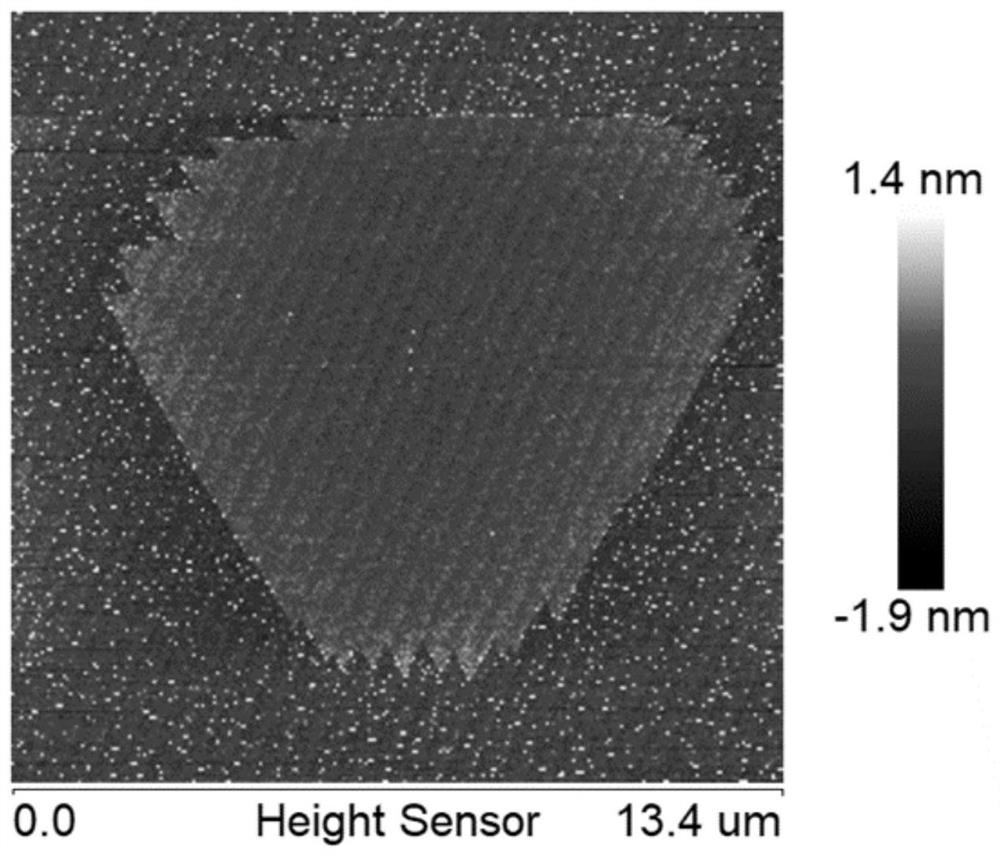

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with specific examples, but the method is not limited to the following examples.

[0044] The chemical vapor deposition system used in the present invention has three discrete heating zones. Wherein, the distance between every two discontinuous heating regions is 30 cm, and the above distance can also be properly adjusted according to the size of the chemical vapor deposition system itself. When using the chemical vapor deposition system to grow transition metal chalcogenides, the carrier gas is introduced into the chemical vapor deposition system, and the heating area close to the upstream along the direction of the flow of the carrier gas is defined as the upstream temperature zone, and the heating area close to the upstream along the direction of the flow of the carrier gas is defined as the upstream temperature zone. The downstream heating area is defined as the downstream temperature zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com