Corrosion process for reducing thickness deviation value of damaged layer of wafer

A wafer and damage layer technology, applied in the field of semiconductor silicon wafer processing, can solve the problems of uneven corrosion thickness and large deviation value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

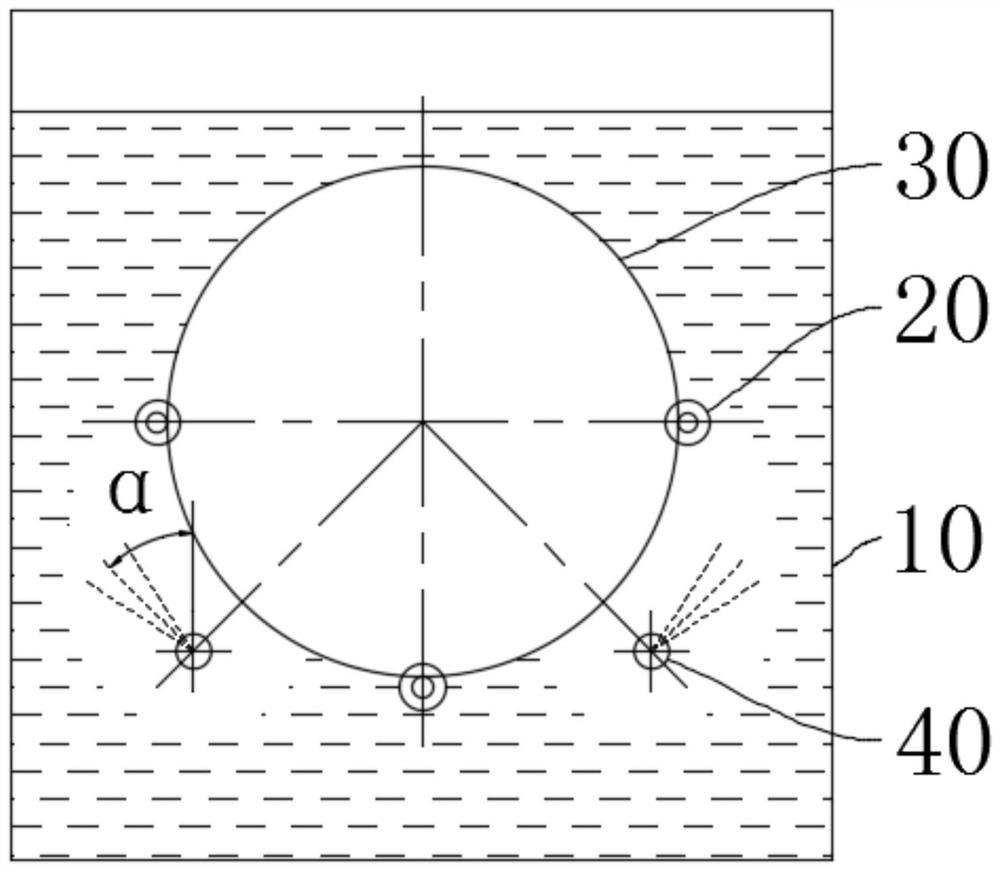

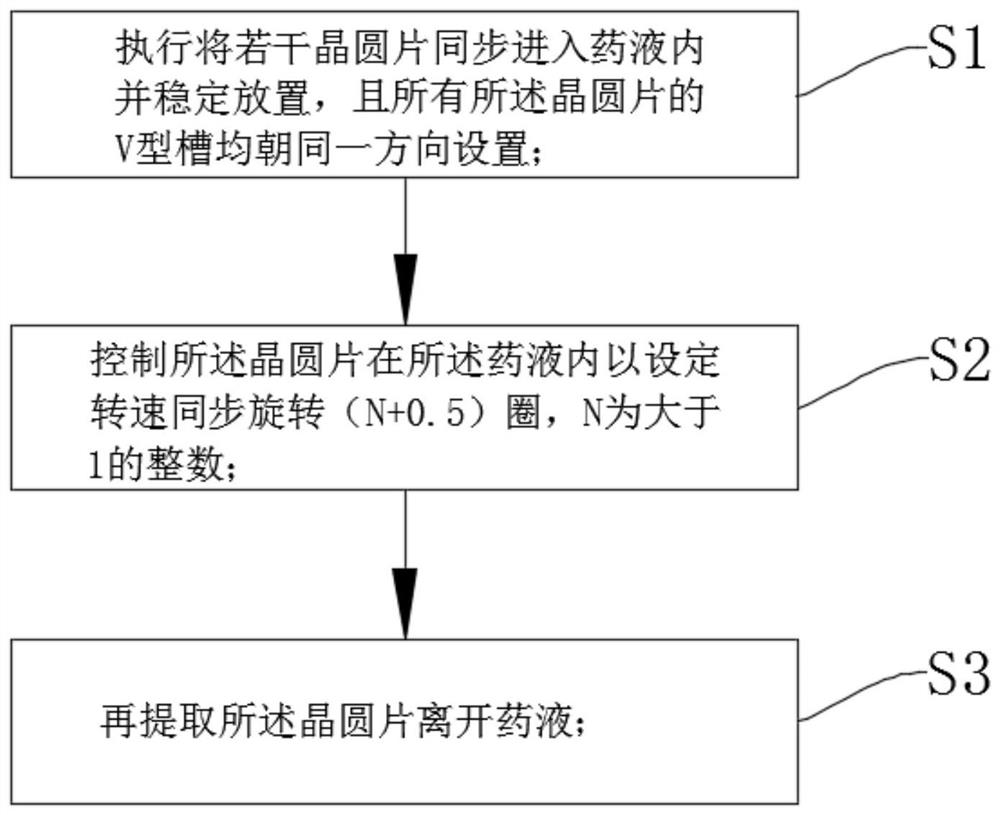

[0041] The wafer 30 diameter is the wafer of 300mm to etch, specifically as follows:

[0042] S1: Put the wafer 30 into the liquid medicine and place it stably

[0043] A plurality of wafers 30 are vertically clamped by a mobile manipulator and vertically enter the liquid medicine, wherein the V-shaped grooves of all wafers 30 are vertically set upwards; the time taken from entering the liquid medicine to placing and leaving for 8s.

[0044] Wherein, the mass concentration of the medicinal solution is a pure solution of potassium hydroxide of 45%, the constant temperature of the medicinal solution is 82° C., and the circulating flow rate of the medicinal solution is 30 L / min; Nitrogen gas is bubbled upward, and the angle α between the direction of nitrogen gas injection and the vertical diameter of the wafer 30 is 45°.

[0045] S2: controlling the wafer 30 to rotate synchronously

[0046] After the wafer 30 is placed stably, control the adjustment lever 20 to rotate the wafer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com