Substrate treatment apparatus

A substrate processing device and substrate technology, which is applied in the direction of lasers, laser welding equipment, electrical components, etc., can solve the problems of limited etching uniformity, difficulty in meeting the miniaturization of circuit patterns, etc., and achieve excellent etching process and high-performance etching Process, the effect of increasing the amount of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

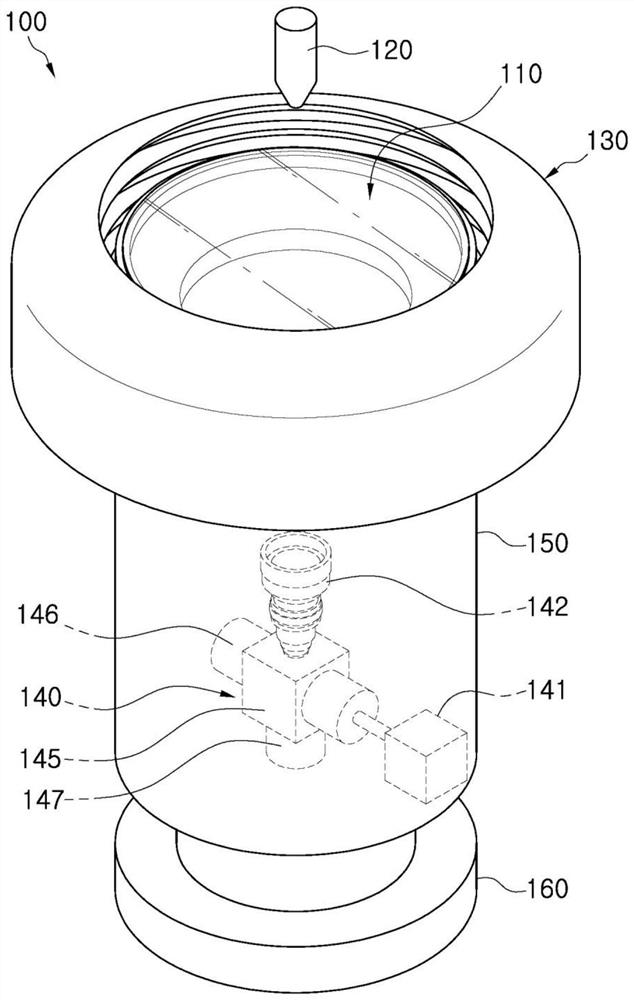

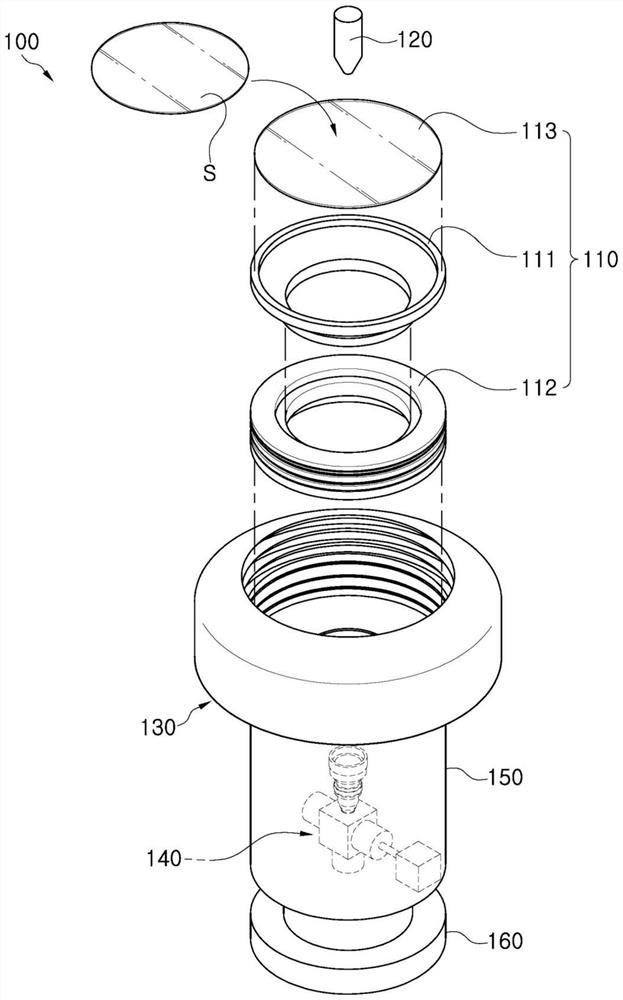

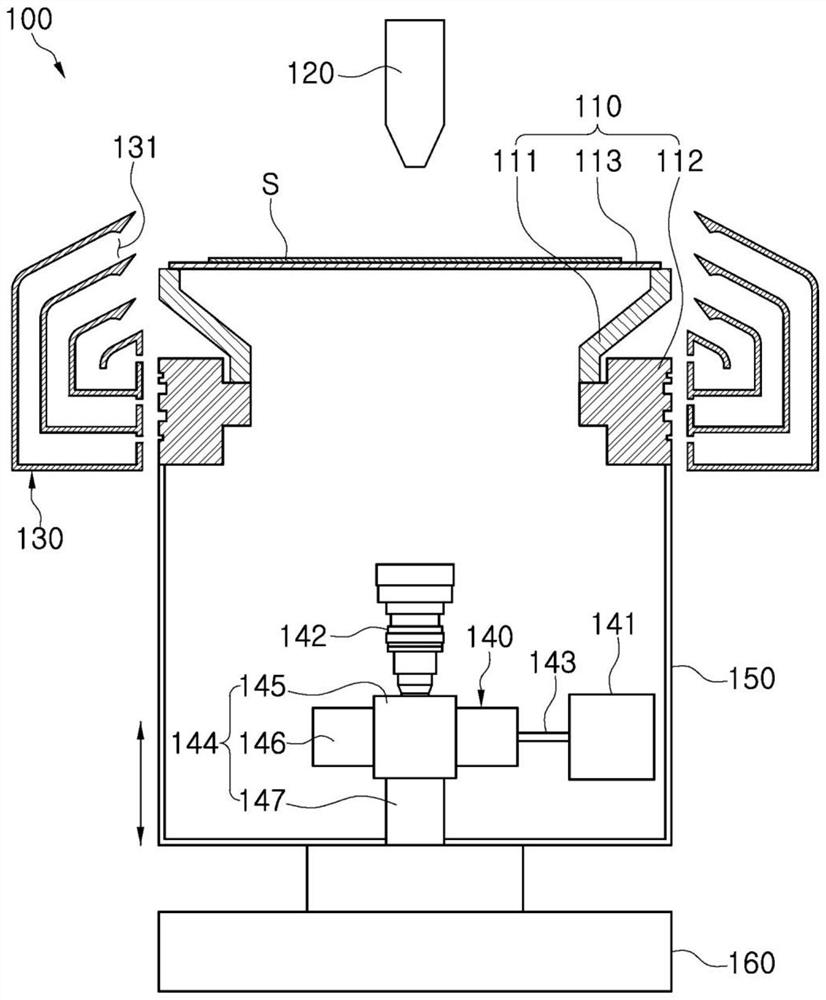

[0048] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those having ordinary knowledge in the technical field to which the present invention pertains can easily implement. The present invention can be realized in various forms and is not limited to the embodiments described here.

[0049] In order to clearly describe the present invention, parts irrelevant to the description are omitted, and the same reference numerals are attached to the same or similar constituent elements throughout the entire specification.

[0050] In addition, in each embodiment, the same reference numerals are used for the constituent elements having the same structure, and only the representative embodiment will be described, and in the remaining other embodiments, only the structures different from the representative embodiment will be described. illustrate.

[0051]Throughout the specification, when it is said that a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com