Preparation method of lentinus edodes extract containing NMN

A technology of shiitake mushroom extract and shiitake mushroom, applied in food science, function of food ingredients, food ultrasonic treatment, etc., can solve the problems of inability to extract NMN and low efficiency of NMN

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a shiitake mushroom extract containing NMN, comprising:

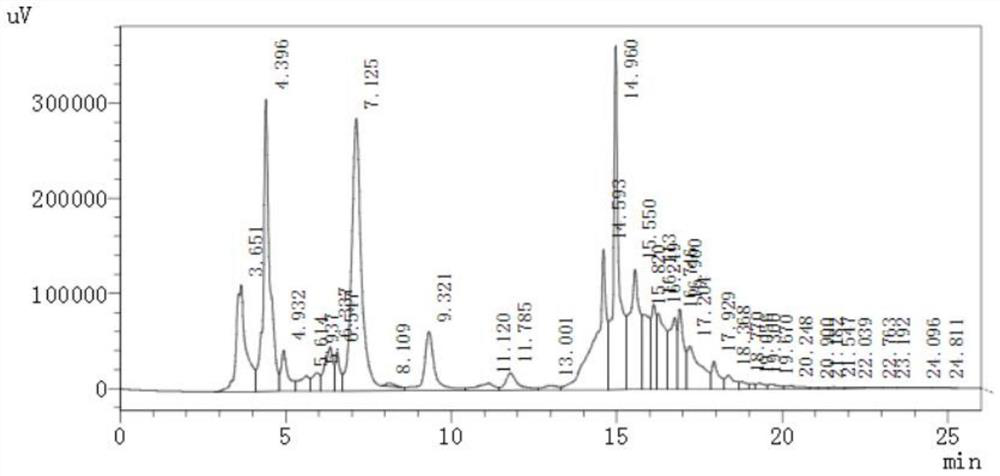

[0038] Add 200 kg of fresh shiitake mushrooms (picked in the first three days) to 600 liters of 75% ethanol, sonicate for 30 minutes, soak for 24 hours, filter, carry out molecular distillation (control temperature 83°C, vacuum degree below 30bar), remove a large amount of ethanol and water , The concentrated solution was left to stand for more than 3 hours, the supernatant was taken, and freeze-dried to obtain 3.126 kg of powder. Detected by HPLC, the NMN content was 3.2%. The molecular weight of NMN in it was 334 as detected by liquid chromatography-mass spectrometry.

Embodiment 2

[0040] A preparation method of a shiitake mushroom extract containing NMN, comprising:

[0041] Add 1000 kg of fresh shiitake mushrooms (picked five days ago) with 3000 liters of 70% ethanol, ultrasonic for 33 minutes, soak for 12 hours, filter, molecular distillation (control temperature 85°C, vacuum below 30bar), remove a large amount of ethanol and water, Let the concentrated solution stand for more than 3 hours, take the supernatant, and spray dry it with a spray dryer with a product cooling collection system (inlet air temperature 150° C.) to obtain 15.523 kg of powder. As detected by HPLC, the NMN content was 3.3%. Liquid-mass spectrometer detection, wherein the molecular weight of NMN is 334.

Embodiment 3

[0043] A preparation method of a shiitake mushroom extract containing NMN, comprising:

[0044] Fresh shiitake mushrooms (picked two days ago) 2,000 kg plus 6,000 liters of 73% ethanol, ultrasonicated for 28 minutes, soaked for 36 hours, filtered, molecularly distilled (control temperature 80°C, vacuum below 30bar), after removing a large amount of ethanol and water, the The concentrate was left to stand for more than 3 hours, and the supernatant was taken, and spray-dried with a spray dryer with a product cooling collection system (inlet air temperature 150° C.) to obtain 31.6 kg of powder. As detected by HPLC, the NMN content was 3.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com