Resourceful treatment system for recycling iron from steel slag and grinding

A steel slag recycling and processing system technology, applied in the field of building materials metallurgy, can solve the problems of high metal iron content, limited drying heat source, poor grindability, etc., achieve full combustion, increase dispersion, and reduce the risk of flame backfire Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

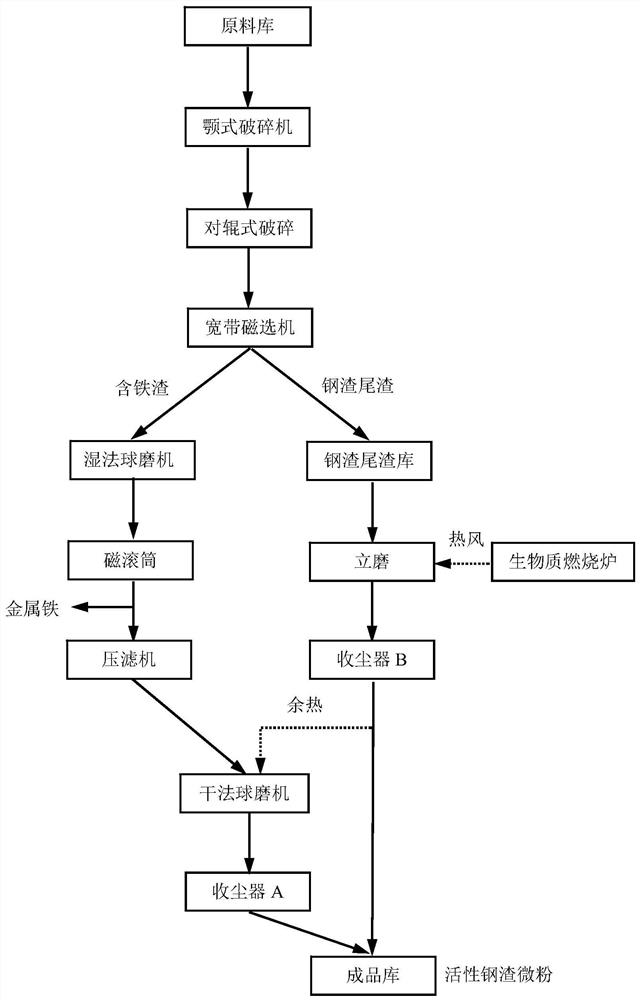

[0043] A steel slag recycling iron and grinding recycling processing system, said steel slag recycling iron and grinding recycling processing system includes: raw material storage, jaw crusher, roller crusher, broadband magnetic separator, wet beneficiation Ball mill, magnetic drum, filter press, dry ball mill, dust collector A, steel slag tailings warehouse, vertical mill, dust collector B, finished product warehouse; the raw material warehouse, jaw crusher, roller crusher, Broadband magnetic separator, wet-process beneficiation ball mill, magnetic drum, filter press, dry-process ball mill, dust collector A and finished product storehouse are connected sequentially, said broadband magnetic separator, steel slag tailing storeroom, vertical mill, dust collector B. Finished product warehouses are connected sequentially.

[0044] Furthermore, it can also be considered in the embodiments that the particle size after crushing by the jaw crusher is ≤30 mm, and the particle size afte...

Embodiment 2

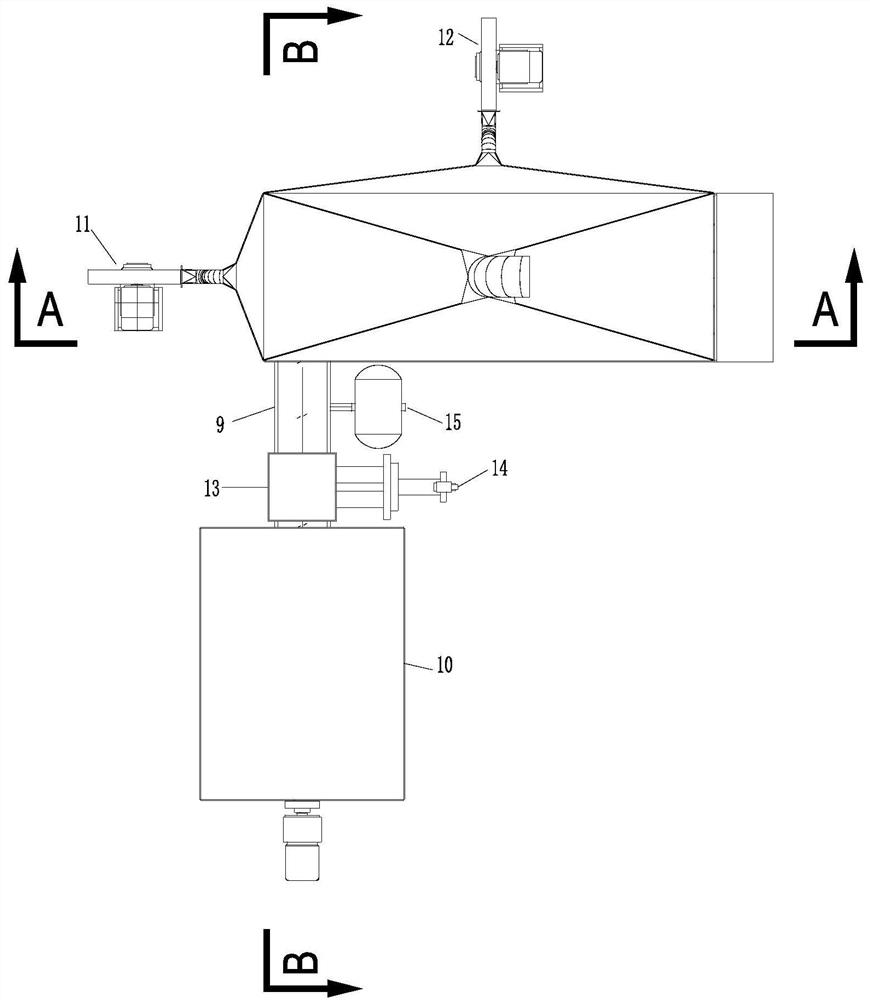

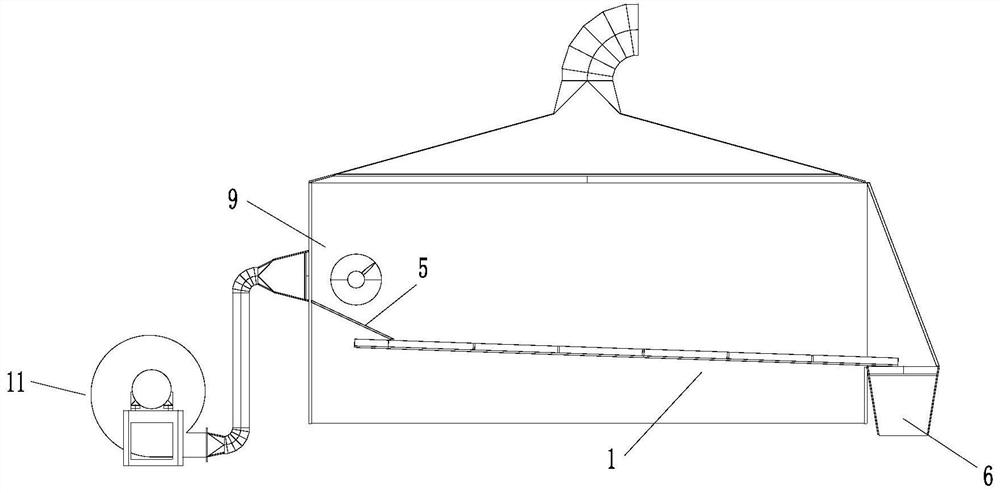

[0052] The heating system of the vertical mill adopts a biomass burning furnace. The biomass burning furnace includes a walking grate bed structure of the biomass burning furnace, and the walking grate bed structure of the biomass burning furnace is arranged in the biomass burning furnace, and the walking grate bed structure includes a driving device and several The traveling grate plate is arranged in parallel, the driving device drives the traveling grate plate to reciprocate along its central axis, and the traveling grate plate moves to the slagging outlet of the biomass combustion furnace and retreats in batches, and the receding The traveling grates are separated by at least one traveling grate.

[0053] The driving device is a hydraulic cylinder, the pull rod of the hydraulic cylinder is fixed to the traveling grate plate, the hydraulic cylinder is installed under the traveling grate plate, the hydraulic cylinder has an accumulator, and the traveling grate plate The hea...

Embodiment 3

[0055] The heating system of the vertical mill adopts a biomass burning furnace. The biomass combustion furnace also includes a safety brake structure for the biomass combustion furnace. The biomass combustion furnace is fed through a conveying reamer, and a steady flow bin is provided at the feed port of the conveying reamer. The conveying hinge A river sand storage tank and an air cannon are installed between the steady flow bin and the biomass burning furnace, and a pneumatic gate valve is installed on the pipeline between the river sand storage tank and the conveying reamer, and the river sand storage tank Located above the pneumatic gate valve, the interior is filled with river sand. When the pneumatic gate valve is opened, the river sand will automatically flow out from the river sand storage tank.

[0056] The capacity of the river sand storage tank is 0.5-1m 3 , the river sand particle size is 0.075-2.36mm; the working pressure of the air cannon is 0.4-1.0MPa, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com