Automatic marking device for cylindrical neodymium iron boron magnetic steel

An automatic marking and NdFeB technology, applied in printing devices, packaging automatic control, packaging, etc., can solve the problems of large marking differences, low marking efficiency, and the decline in the production pass rate of cylindrical NdFeB magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

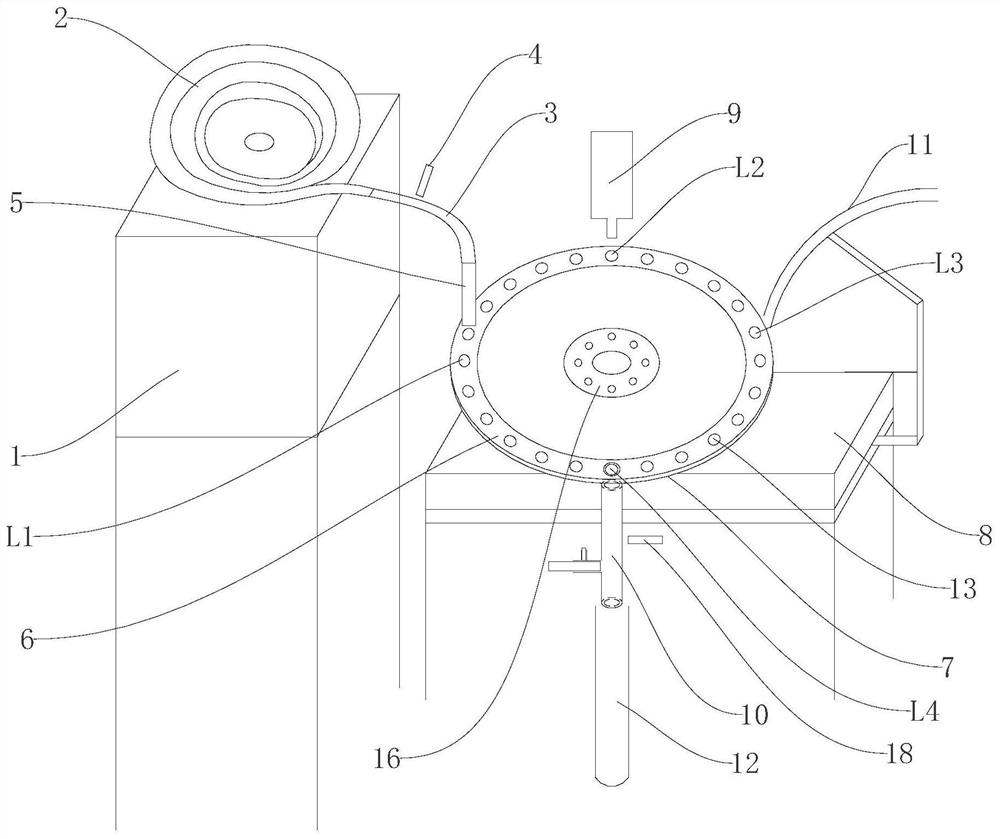

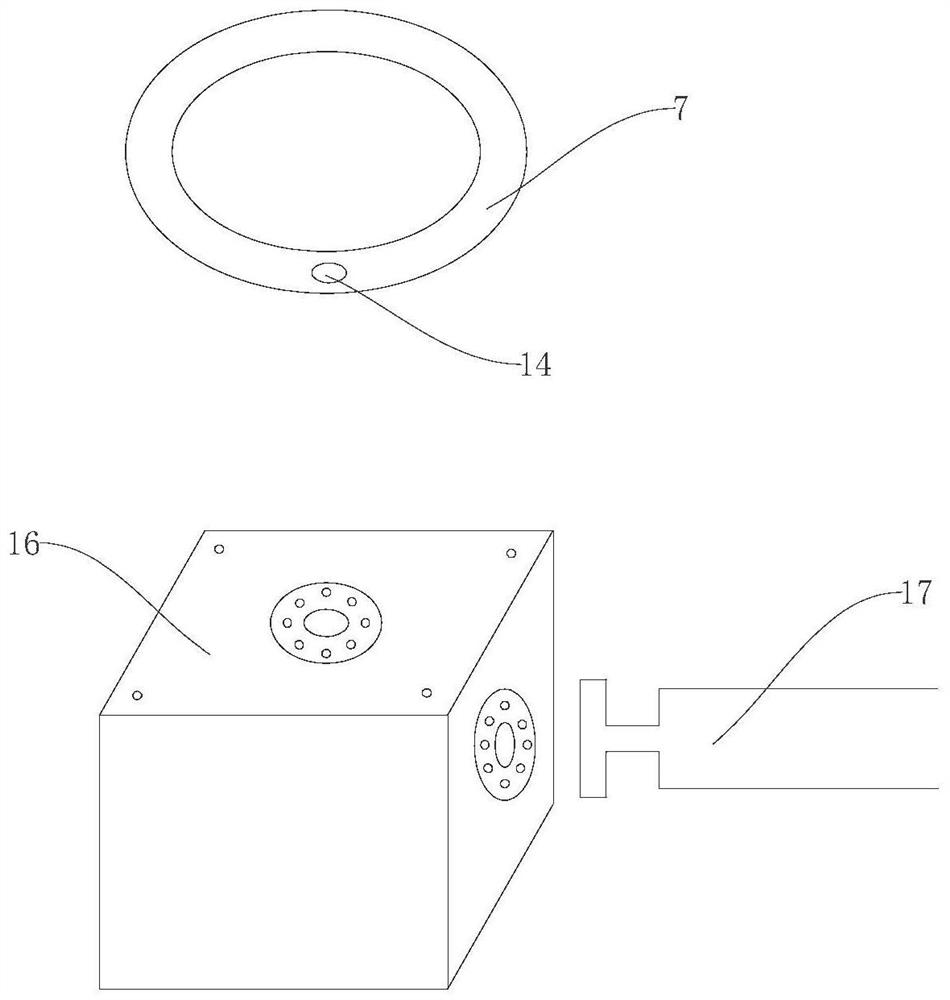

[0013]Example:figure 1 withfigure 2As shown, an automatic marking device of a cylindrical neodymium iron boron magnetic steel includes a control module, a support table 1, a vibrating plate 2, a feed hose 3, a first fiber optic fiber passed by a cylindrical NdFeB magnetic steel. Sensor 4, guiding passage 5, rotary disk 6, support disk 7, a table 8, a drive, a printer 9, a feed pipe 10, a gas pipe 11, and a hose for packaging cylindrical NdFeB magnetic steel 12, the control module is connected to the vibrating feed pan 2, the first fiber sensor 4, the driver, and the prisoner 9, and the vibrating feed pan 2, the driver, and the inkjet printer 9 can be controlled, and the workbench is sequentially provided in sequence The station L1, the labeling station L2, the drying station L3, and the feedstock L4, the driver is mounted on the table 8, and the rotary disk 6 is mounted on the drive, and the support disk 7 is located below the rotating disk 6, and is fixed On the drive, the printer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com