Iron tailings foam concrete and preparation method thereof

A technology of foam concrete and iron tailings, which is applied in the field of foam concrete and foam concrete lightweight materials, can solve problems such as large safety hazards, environmental impact, casualties, etc., and achieve the effects of quality assurance, strength improvement, and strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

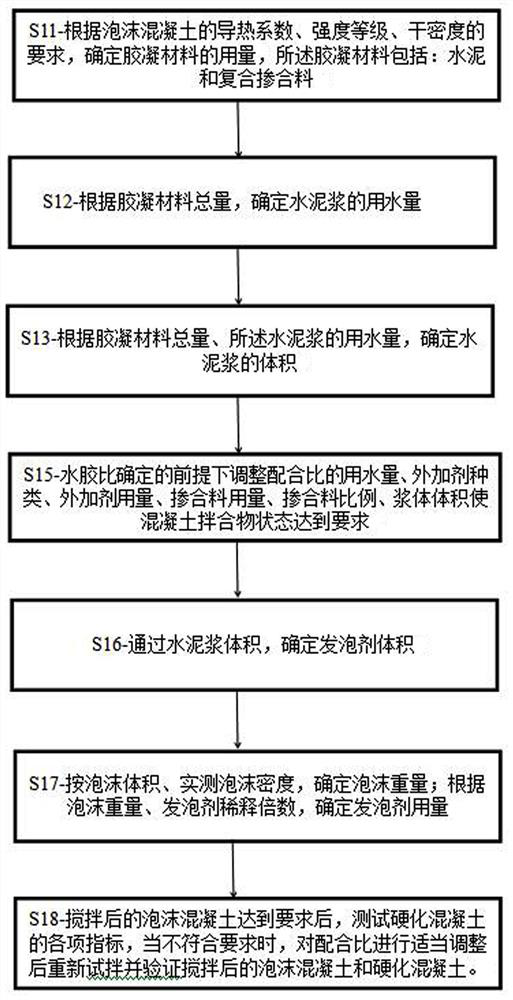

Method used

Image

Examples

Embodiment 1

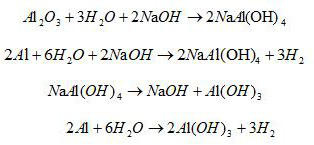

[0049] In the present embodiment, the bulk density of the foamed concrete is 700kg / m 3 At that time, the proportion of mixing is as follows: cement is 360kg / m³, the content of composite admixture is 326kg / m³, the content of foam stabilizer is 2.1kg / m³, the content of water is 280kg / m³, the content of epoxy resin is 2.1kg / m³, The content of the alkaline activator is 14kg / m³, the foaming agent (YS-10 cement foaming agent and aluminum powder are mixed in 1:1; the fineness of the aluminum powder is 200-250 mesh, and the content of activated alumina is 85- 90%) with a content of 4.7kg / m³; the preparation method of the composite admixture: mechanically pulverize and finely grind the iron tailings, add an alkaline activator (using 95% to 98% NaOH and NaOH with a modulus of 1.3 2 SiO 3 mixed alkaline solution), then add fly ash and slag; by weight percentage, which contains 50% iron tailings, 18% slag, 30% fly ash, 2% alkaline activator. The iron tailings are high-silicon iron taili...

Embodiment 2

[0062] In the foamed concrete, when the bulk density of the foamed concrete is 800kg / m³, its compounding proportion is as follows: the cement content is 320kg / m³, the composite admixture content is 464kg / m³, the foam stabilizer content is 2.1kg / m³, water content of 320kg / m³, epoxy resin content of 3.4kg / m³, alkaline activator (using 95%~98% NaOH and NaOH with a modulus of 1.3 2 SiO 3 mixed alkaline solution) with a content of 16kg / m³, foaming agent (YS-10 cement foaming agent and aluminum powder mixed in 1:1; the fineness of the aluminum powder is 200-250 mesh, activated alumina The content is 85-90%) and the content is 4kg / m³; the preparation method of the composite admixture: mechanically pulverize and finely grind the iron tailings, add an alkaline activator (95%-98% NaOH and a modulus of 1.3 Na 2 SiO 3 mixed alkaline solution), then add fly ash and slag; by weight percentage, which contains 50% iron tailings, 18% slag, 30% fly ash, 2% alkaline activator . The iron tai...

Embodiment 3

[0066] In the foam concrete, the bulk density of the foam concrete is 900kg / m³, and its proportion is as follows: the cement content is 280kg / m³, the composite admixture content is 602kg / m³, the foam stabilizer content is 2.1kg / m³, the water content The content of epoxy resin is 360kg / m³, the content of epoxy resin is 4.3kg / m³, and the basic activator (using 95%~98% NaOH and NaOH with a modulus of 1.3 2 SiO 3 mixed alkaline solution) with a content of 18kg / m³; foaming agent (YS-10 cement foaming agent mixed with aluminum powder at 1:1; the fineness of the aluminum powder is 200-250 mesh, activated alumina The content is 85-90%) and the content is 3.4kg / m³; the preparation method of the composite admixture: mechanically pulverize and finely grind the iron tailings, add an alkaline activator (using 95%-98% NaOH and a modulus of 1.3Na 2 SiO 3 mixed alkaline solution), then add fly ash and slag. In terms of weight percentage, it contains 50% iron tailings, 18% slag, 30% fly as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com