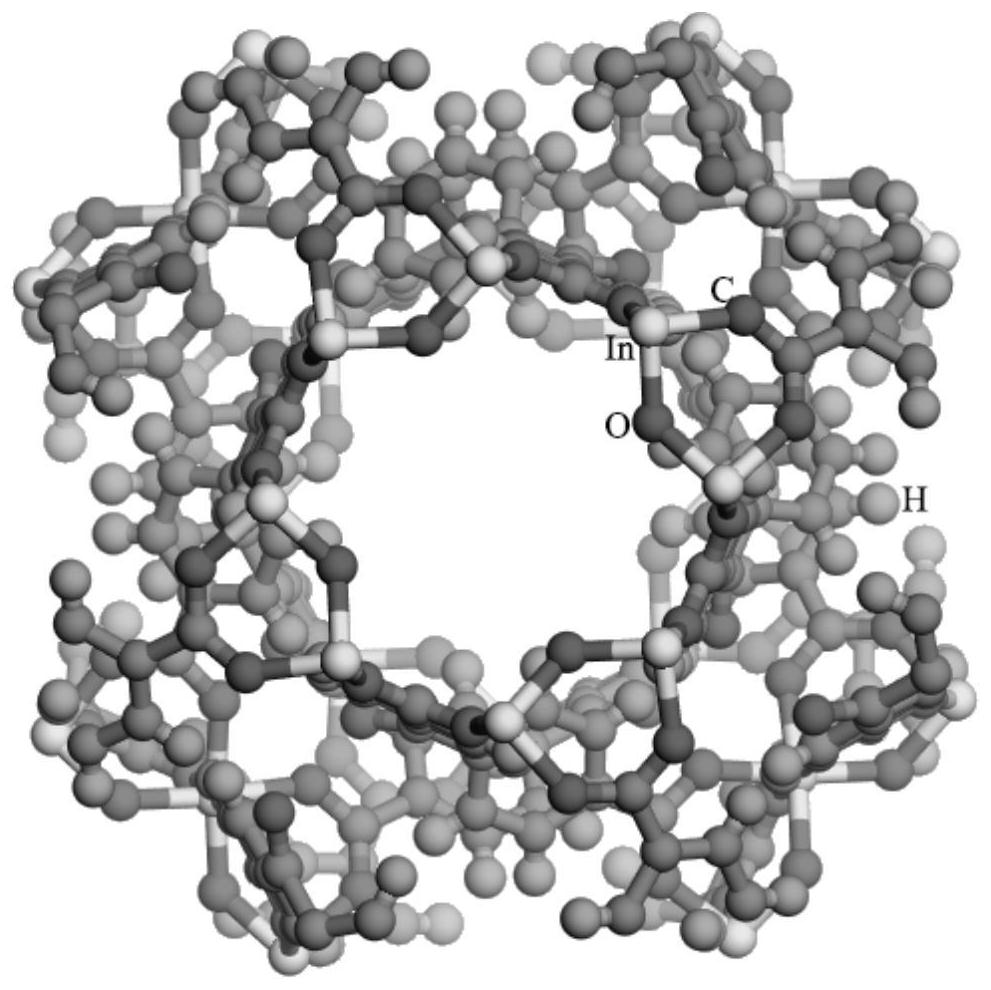

Preparation method and application of indium-based metal organic framework material

An organic framework and metal-based technology, which is applied in the field of preparation of indium-based metal-organic framework materials, can solve the problems of low utilization rate of coalbed methane, poor separation effect, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing an indium-based metal organic framework material in an embodiment of the present invention includes the following steps:

[0026] Synthesis of indium metal clusters: Dissolve anhydrous sodium formate and indium trichloride in water respectively to obtain sodium formate solution and indium trichloride solution; then drop the sodium formate solution into the indium trichloride solution, heat and stir , to obtain a suspension; the suspension is suction filtered, and the filter residue is taken; the filter residue is washed and dried to obtain indium metal clusters;

[0027] Synthesis of indium-based metal organic framework materials: disperse the indium metal clusters in N,N-dimethylformamide to obtain the first mixed solution; disperse benzophenone-4,4'-dicarboxylic acid in N , in N-dimethylformamide, to obtain a second mixed solution; then the second mixed solution is added dropwise to the first mixed solution, and formic acid and H are added 2 0,...

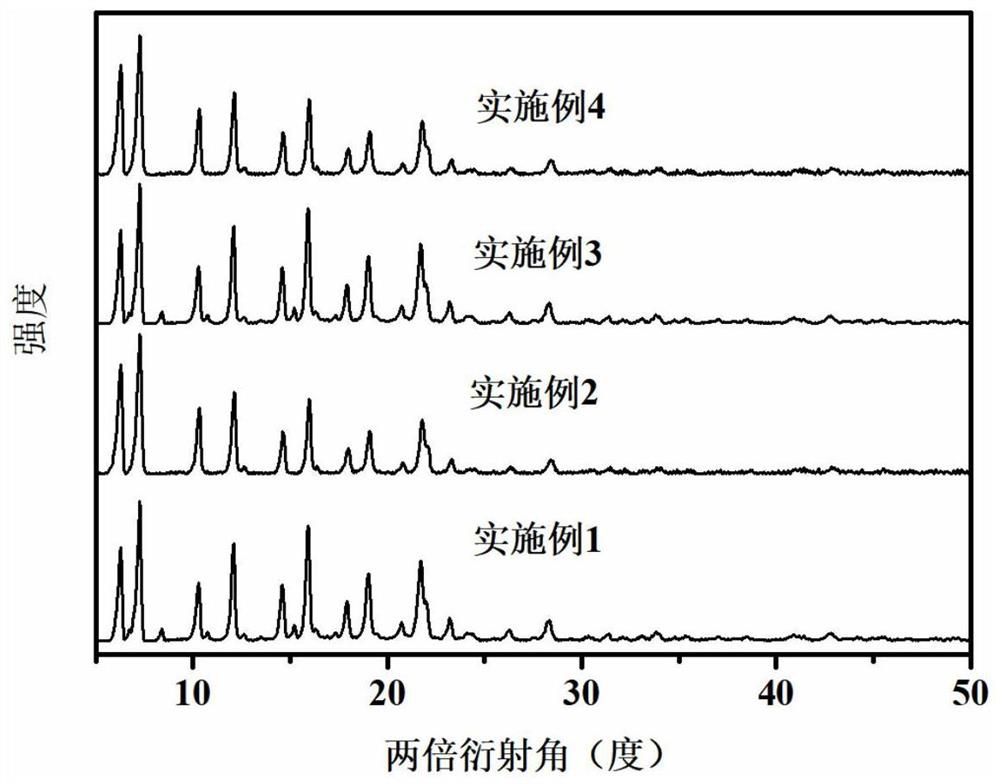

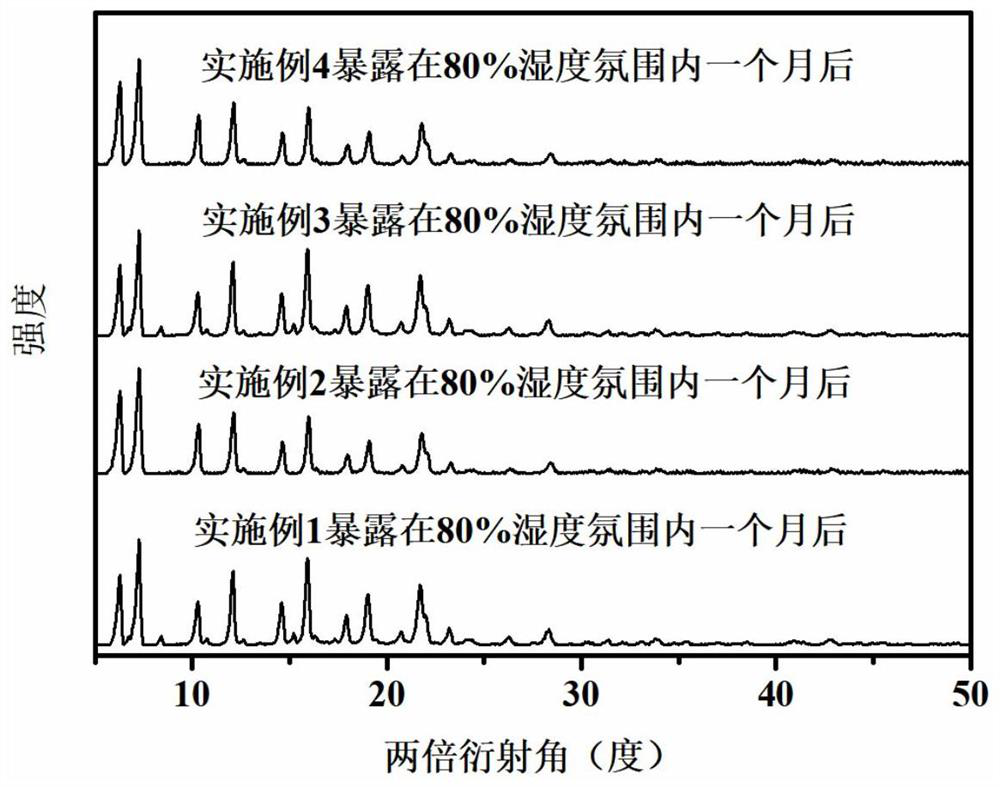

Embodiment 1

[0044] A method for preparing an indium-based metal organic framework material, comprising the steps of:

[0045] (1) Synthesis of indium metal clusters: Dissolve 22.12g of indium trichloride in 60mL of water to obtain an indium trichloride solution; dissolve 21.08g of anhydrous sodium formate in 60mL of water to obtain a sodium formate solution; drop the sodium formate solution into In the indium trichloride solution, heat to 40°C and stir for 10 hours to obtain a suspension; filter the suspension with suction and take the filter residue; wash the filter residue with 30mL deionized water and 30mL ethanol in sequence; finally, place at 120°C Dry in an oven for 8 hours to obtain indium metal clusters.

[0046] (2) Synthesis of indium-based metal-organic framework materials: ultrasonically disperse 0.1770g of indium metal clusters in 0.3555g of DMF to obtain the first mixed solution; ultrasonically disperse 0.1770g of benzophenone-4,4'-dicarboxylic acid In 0.3555g DMF, obtain t...

Embodiment 2

[0048] A method for preparing an indium-based metal organic framework material, comprising the steps of:

[0049] (1) Synthesis of indium metal clusters: Dissolve 66.40g of indium trichloride in 60mL of water to obtain an indium trichloride solution; dissolve 21.08g of anhydrous sodium formate in 60mL of water to obtain a sodium formate solution; drop the sodium formate solution into In the indium trichloride solution, heat to 60° C. and stir for 18 hours to form a suspension; then suction-filter the suspension to take the filter residue; wash the filter residue with 30mL deionized water and 30mL ethanol in sequence; finally, place Dry in an oven at 150°C for 16 hours to obtain indium metal clusters.

[0050] (2) Synthesis of indium-based metal-organic framework materials: ultrasonically disperse 0.5280g of indium metal clusters in 2.1330g of DMF to obtain the first mixed solution; disperse 0.5280g of benzophenone-4,4'-dicarboxylic acid in 2.1330 In g DMF, the second mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com