Perovskite material, solar cell device and preparation method

A perovskite material and perovskite technology, applied in the field of materials, can solve problems such as difficulty in adapting to harsh environments, difficulty in suppressing ions, and limited stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

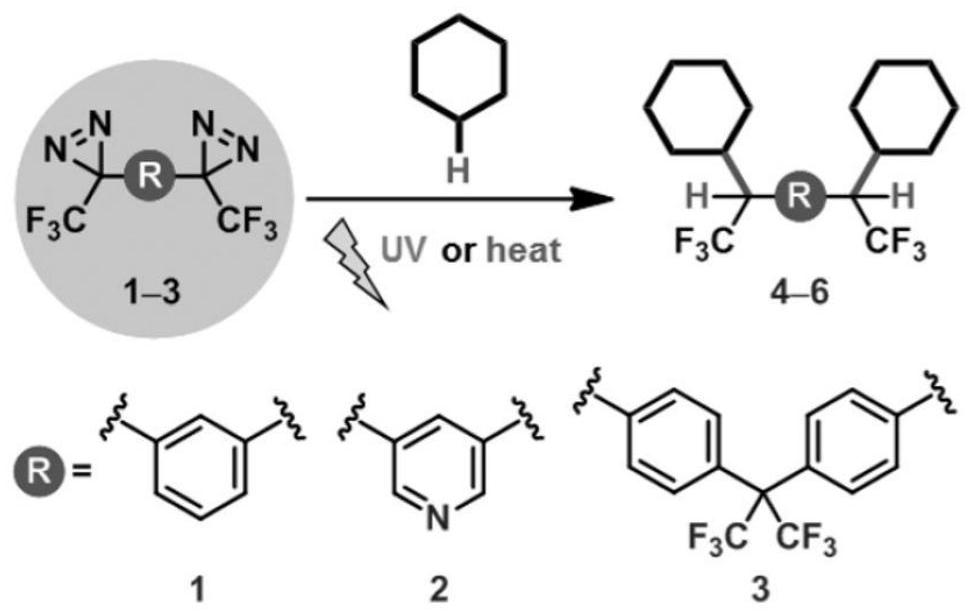

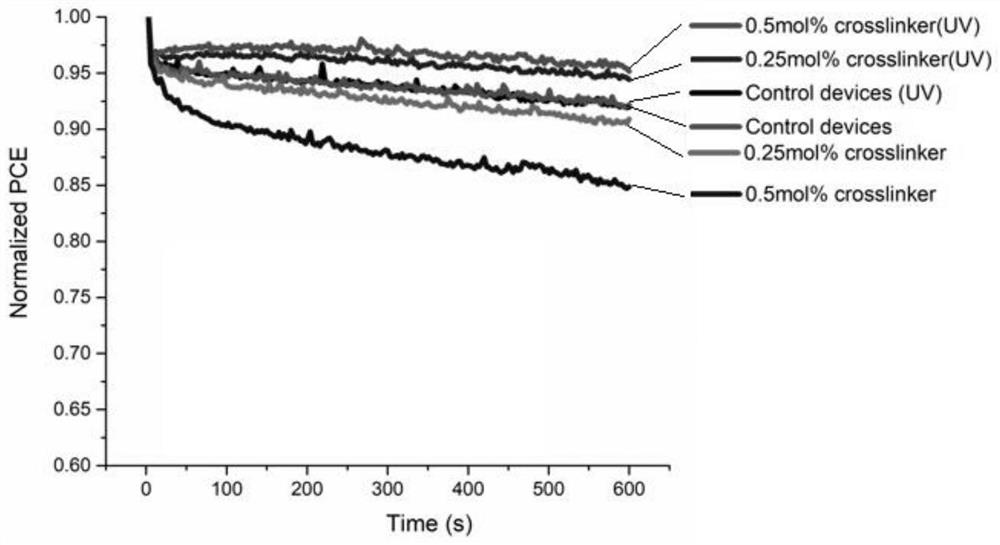

Method used

Image

Examples

Embodiment 1

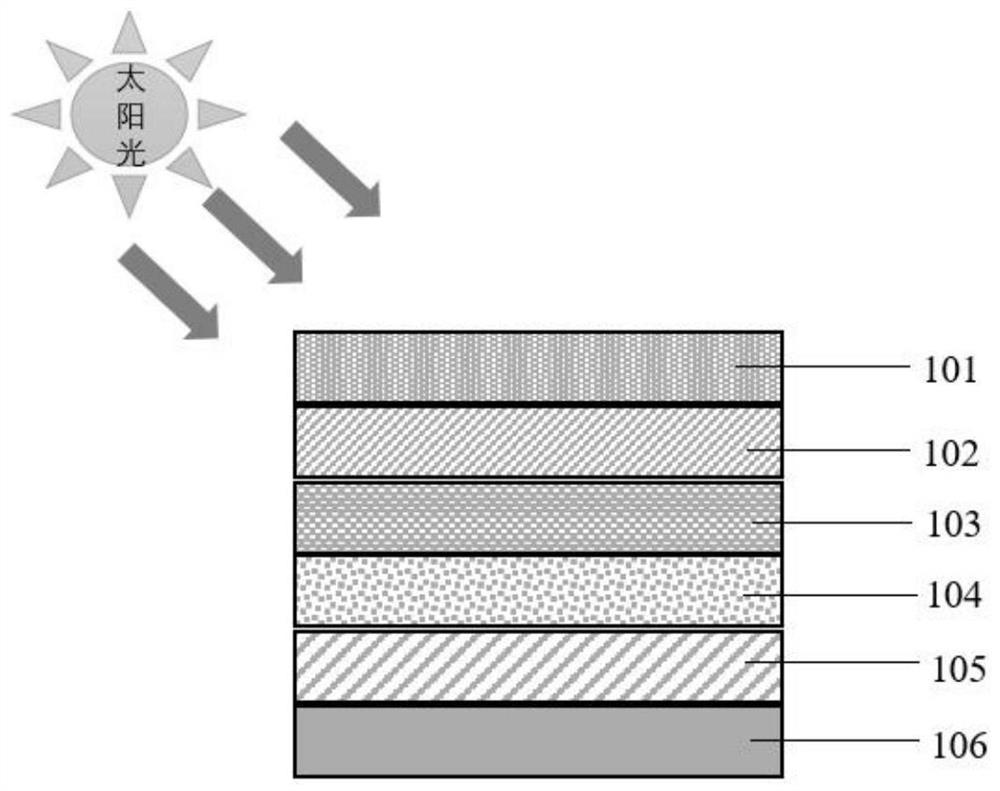

[0038] In this example, an organic-inorganic hybrid perovskite material was prepared and a perovskite solar cell was prepared using the material. The transparent substrate of the perovskite solar cell is quartz glass; the first transparent electrode layer is ITO with a thickness of 180nm; the hole transport layer is Spiro-OMeTAD with a thickness of 40nm; formed; the main component of the perovskite layer is Cs 0.05 (MA 0.13 FA 0.87 ) 0.95 Pb(I 0.87 Br 0.13 ) 3 , the thickness is 580nm; the electron transport layer is SnO 2 , with a thickness of 30nm; the second electrode layer is gold with a thickness of 80nm. The preparation steps of perovskite solar cells are as follows:

[0039] (1) ITO conductive glass is cleaned with glass cleaning solution, acetone, and ethanol in sequence, and after drying, use an ultraviolet ozone cleaner to remove residual organic matter.

[0040] (2) 360μL SnO 2 Mixed with 2.4mL deionized water, prepared SnO by spin coating method 2 After ...

Embodiment 2

[0045] In this example, an organic-inorganic hybrid perovskite material was prepared and a perovskite solar cell was prepared using the material. The transparent substrate of the perovskite solar cell is quartz glass; the first transparent electrode layer is ITO with a thickness of 180nm; the electron transport layer is SnO 2 , with a thickness of 30nm; the perovskite layer is (FAPbI 3 ) 1-x-y (MAPbBr 3 ) x ) (MAPbCl 3 ) y ), where x, y, and 1-x-y are greater than or equal to 0 and less than or equal to 1 respectively, and the thickness is 700nm; the hole transport layer is Spiro-OMeTAD, and the thickness is 100nm; the second electrode layer is gold, and the thickness is 80nm. The preparation steps of the perovskite solar cell of the present embodiment are as follows:

[0046] (1) ITO conductive glass is cleaned with glass cleaning solution, acetone, and ethanol in sequence, and after drying, use an ultraviolet ozone cleaner to remove residual organic matter.

[0047] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com