Straw biological fermentation system and method

A fermentation system and straw biological technology are applied in the field of straw biological fermentation system, which can solve the problems of time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

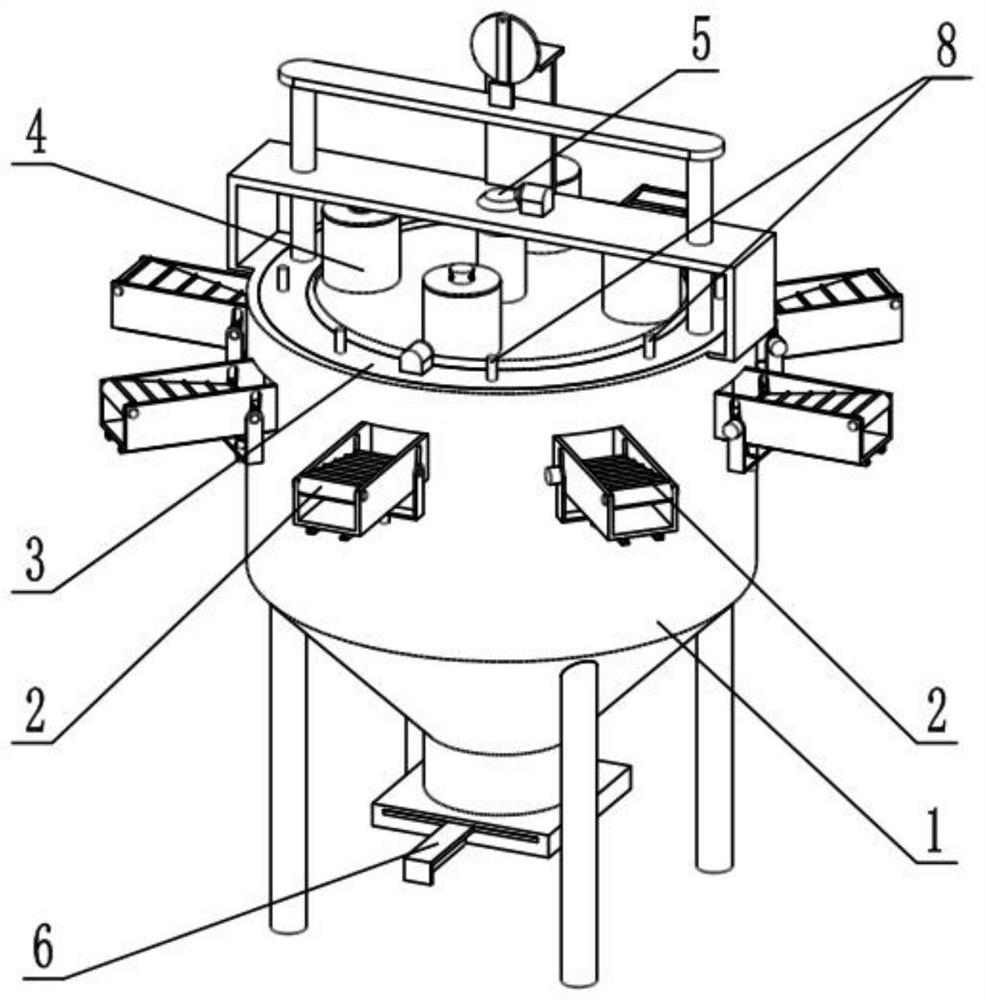

[0034] Such as Figure 1-10 As shown, a straw biological fermentation system includes a fermentation box 1, a straw pushing mechanism 2, a chopping mechanism 3, an auxiliary material box 4, a stirring mechanism 5, a bottom blocking mechanism 6, an auxiliary material adding mechanism 7 and a nozzle 8, and is characterized in that : the straw pushing mechanism 2 is provided with a plurality, and the plurality of straw pushing mechanisms 2 are evenly connected to the outer end of the fermentation box 1 in the circumferential direction, the described chopping mechanism 3 is connected to the upper end of the fermentation box 1, and the auxiliary materials The box 4 is connected to the chopping mechanism 3, the stirring mechanism 5 is connected in the fermentation box 1 and is slidably connected with the auxiliary material box 4, the bottom sealing mechanism 6 is connected to the lower end of the fermentation box 1, and the auxiliary material Adding mechanism 7 is provided with mult...

specific Embodiment approach 2

[0036] Specific embodiment two: fermenter 1

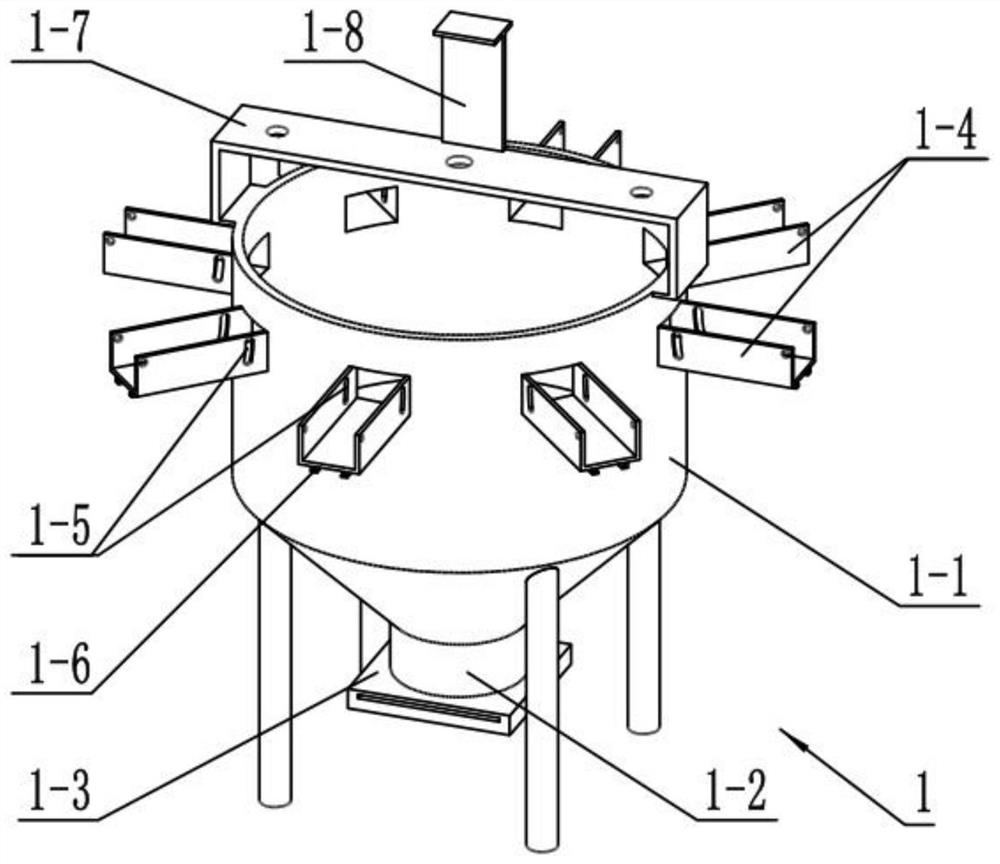

[0037] Such as Figure 1-10As shown, the fermentation box 1 includes a box body 1-1, a discharge pipe 1-2, a base 1-3, a straw trough plate 1-4, an arc-shaped sliding hole 1-5, a chute 1-6, an upper The horizontal plate 1-7 and the mounting plate 1-8, the lower end of the box body 1-1 is tapered, the discharge pipe 1-2 is fixedly connected to the lower end of the box body 1-1, and the base 1-3 is fixedly connected to the discharge pipe At the lower end of 1-2, there are multiple straw troughs 1-4, and the plurality of straw troughs 1-4 are evenly fixed and connected to the outer end of the upper part of the box body 1-1 in the circumferential direction, and the plurality of straw troughs 1-4 The lower end is provided with chute 1-6, a plurality of stalk troughs 1-4 are provided with arc-shaped slide holes 1-5, and the upper horizontal plate 1-7 is fixedly connected to the upper end of the box body 1-1. Board 1-8 is fixedly connec...

specific Embodiment approach 3

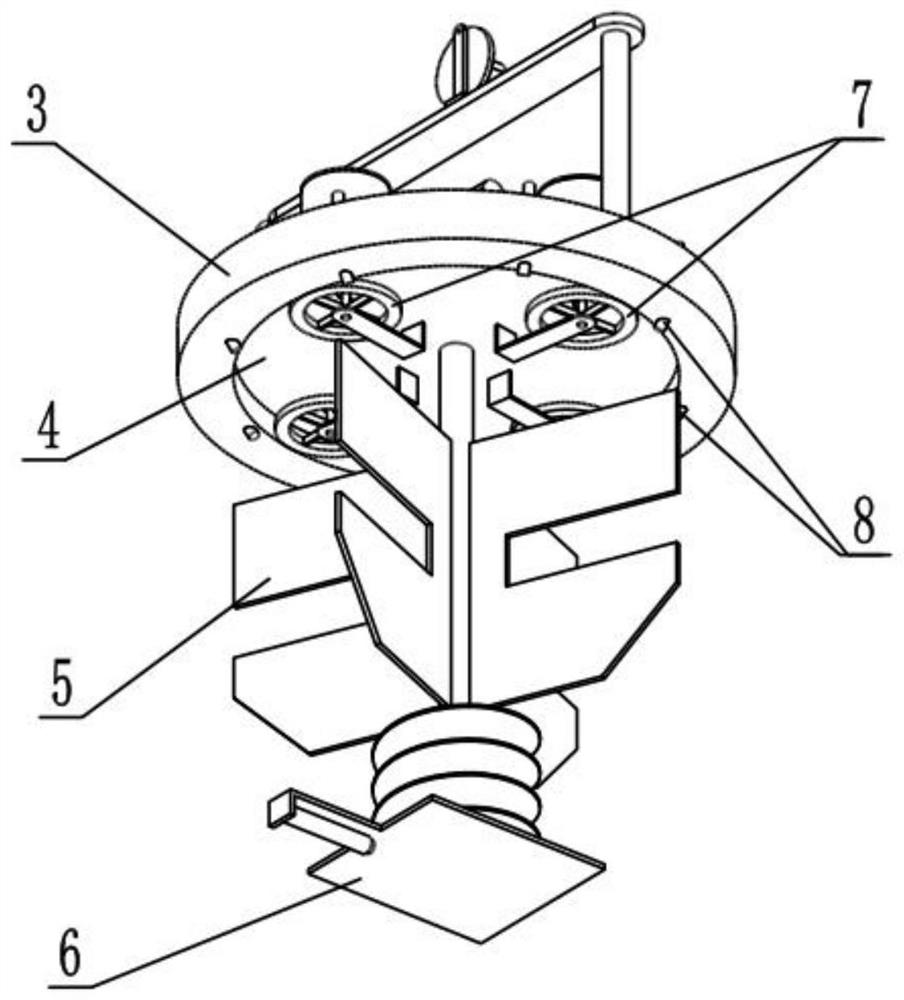

[0040] Such as Figure 1-10 As shown, the straw pushing mechanism 2 includes a fixed roller 2-1, a sliding roller 2-2, a clamping conveyor belt 2-3, a connecting frame 2-4, a sliding plate 2-5, a sliding column 2-6 and a spring 2 -7, the fixed roller 2-1 and the sliding roller 2-2 are connected through the transmission of the clamping conveyor belt 2-3, the sliding roller 2-2 is rotatably connected in the connecting frame 2-4 and the outer end is provided with a driving motor, and the sliding column 2 -6 is slidingly connected to the connecting frame 2-4, the sliding plate 2-5 is fixedly connected to the upper end of the sliding column 2-6, the spring 2-7 is sleeved on the sliding column 2-6, and the two ends of the spring 2-7 respectively Tightly connect the frame 2-4 and the slide plate 2-5, the straw pushing mechanism 2 is provided with a plurality, and a plurality of fixed rollers 2-1 are respectively connected to the outer ends of the straw chute 1-4 in rotation, and a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com