Cold-batch degreasing and bleaching method for pure cotton spunlace non-woven fabric

A technology of spunlace non-woven fabrics and cold stacking, which is applied in the field of bleaching, can solve the problems of long cold stacking time and high bath ratio, and achieve the effects of less consumption, reduced COD value, and lower pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

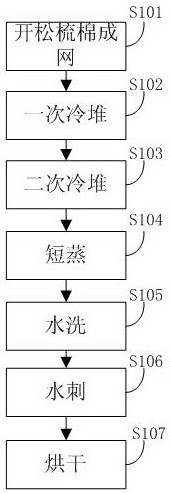

[0049] see figure 2 , embodiment 1 provides a kind of preparation method of non-woven fabric, this method comprises:

[0050] S101 Opening and carding to form a web: Opening and carding to form a web according to the conventional process of non-woven fabrics.

[0051] S102 Primary cold pile: conduct a primary cold pile on the cotton net after cleaning, the conditions of the primary cold pile are: room temperature, time 4h, liquor ratio 1:6. Wherein, the primary cold pile liquid comprises the first composite biological enzyme agent and Pingpingjia, the concentration of the first composite biological enzyme agent is 5g / L, and the concentration of Pingpingjia is 2g / L, and the first composite biological enzyme agent is composed of pectinase, Cellulase, protease and lipase are composed in a mass ratio of 1.6:3:1.5:1.

[0052] S103 Secondary cold pile: The cotton net after primary cold pile is subjected to secondary cold pile. The conditions of secondary cold pile are: room tempe...

Embodiment 2

[0074] The process of embodiment 2 is basically the same as that of embodiment 1, except that in this embodiment, SCJ-2000 is added to the secondary cooling reactor fluid, and the concentration of SCJ-2000 is 1.5g / L.

Embodiment 3

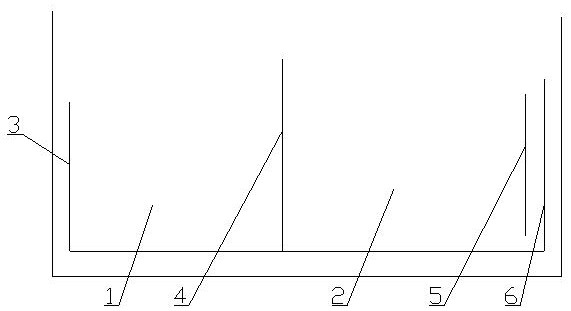

[0076] see image 3, add compound biological enzyme agent in the first cold pile tank 1, carry out a cold pile; Enzymes (neutral, no need to consider enzyme activity) are mixed to obtain secondary cold reactor liquid, and the secondary cold reactor is carried out. Specifically, the compound biological enzyme agent is added before plate 1 3, TAED, hydrogen peroxide, sodium hydroxide and Pingjia are added between plate 3 5 and plate 4 6, the height of the top of plate 2 4 > the height of the top of plate 4 6 > plate The height of the top of board 3 5 > the height of the top of board 1 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com