High-resolution ink-jet printing method

An inkjet printing, high-resolution technology, applied in the field of circuit printing, which can solve the problems of low efficiency, high production cost, and no potential for large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

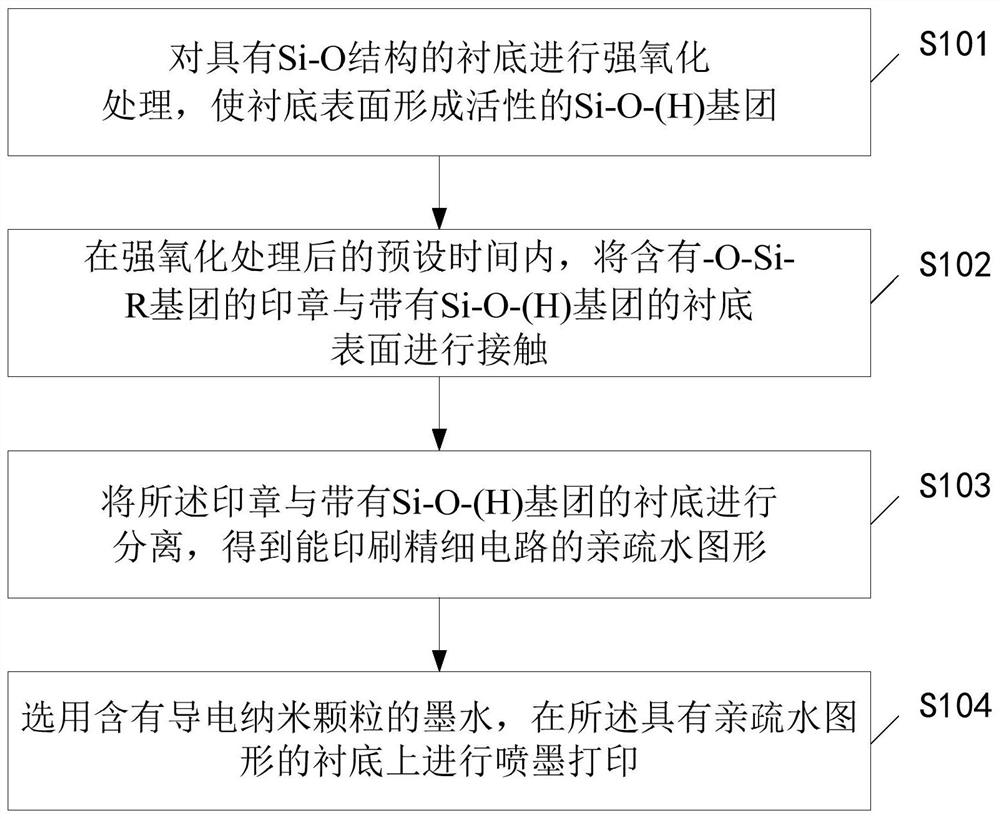

Method used

Image

Examples

preparation example Construction

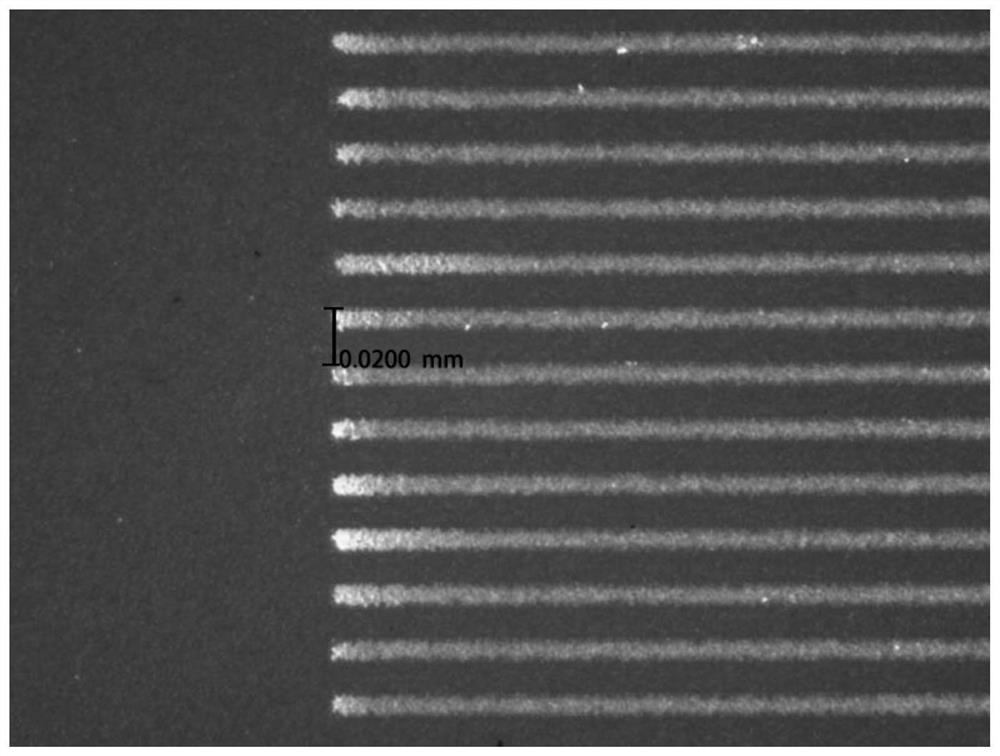

[0081] The invention realizes dry printing in the preparation of hydrophilic and hydrophobic graphics, that is, no ink is needed at all, and graphic aliasing caused by spontaneous movement of ink is fundamentally avoided. Moreover, the present invention adopts dry printing to form hydrophilic and hydrophobic patterns, and the line width of the hydrophilic and hydrophobic patterns is less than 1 mm, even as small as 1-50 μm, which can realize the printing of fine circuits with high resolution.

[0082] S104. Select ink containing conductive nanoparticles, and perform inkjet printing on the substrate with hydrophilic and hydrophobic patterns.

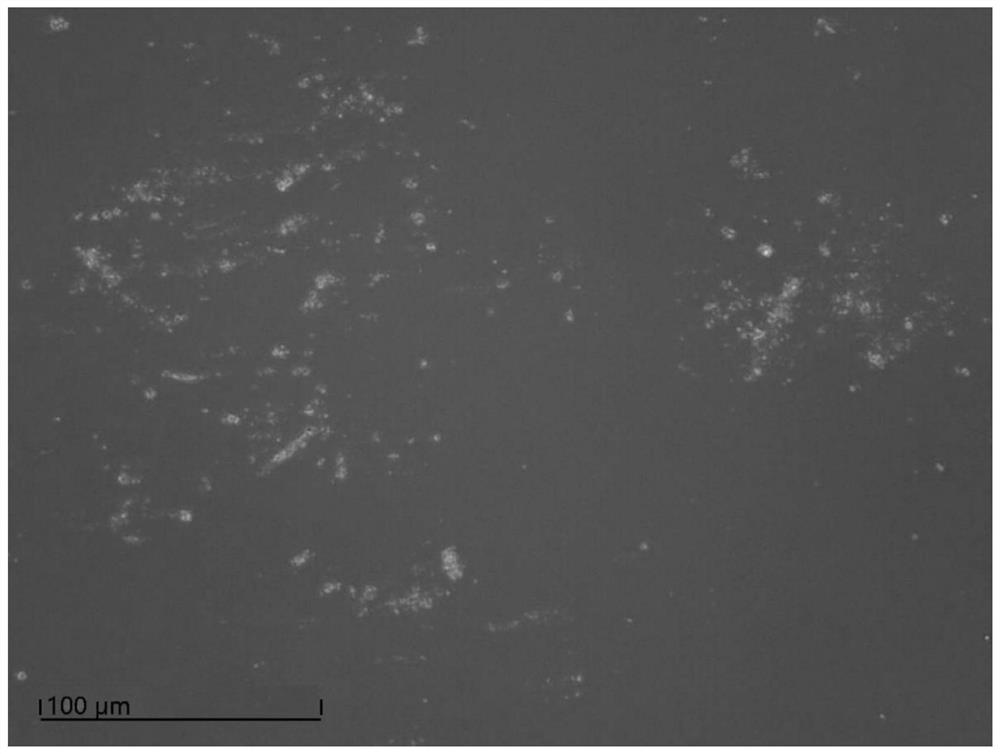

[0083] Those skilled in the art know that compared with parallel thin lines, the difficulty of inkjet printing high-resolution complex graphics containing intersection points will be significantly increased. The reason is that low-viscosity inks move spontaneously, or shrink spontaneously due to surface tension. Taking the triangular pat...

Embodiment 1

[0119] (1) select a seal made of silicone rubber containing -O-Si-R groups, and the seal is made of polydimethylsiloxane;

[0120] (2) Use glass as the substrate;

[0121] (3) The substrate is subjected to strong oxidation treatment for 5-50 minutes (preferred time is 30 minutes) with the highly active ozone component produced by the ultraviolet cleaning machine, so that active Si-O-(H) groups are formed on the surface of the substrate group;

[0122] (4) Within 1s after the end of the strong oxidation treatment, quickly roll the printing roller with the stamp fixed on the surface of the substrate with Si-O-(H) groups, and limit the contact pressure to about 1000Pa . The rolling speed is 50 mm / s, and the average contact time between the stamp and the surface of the substrate is approximately 1 ms based on the calculation that the width of the contact area between the printing roller and the plane is 50 microns. Changing the water contact angle of the substrate from about 15...

Embodiment 2

[0128] (1) Select a seal made of silicone rubber containing -O-Si-R groups for use, and the seal is made of methyl vinyl silicone rubber;

[0129] (2) Use glass as the substrate;

[0130] (3) Perform strong oxidation treatment on the substrate, the specific details are: the substrate is treated with an atmospheric pressure plasma treatment spray gun, and the average treatment time is 3-5s. Form active Si-O-(H) groups on the substrate surface;

[0131] (4) Within 30s after the strong oxidation treatment, quickly roll the stamp roller fixed with the stamp over the surface of the substrate with Si-O-(H) groups, and limit the contact pressure to about 2000Pa. The rolling speed is 5 mm / s, and the average contact time between the stamp and the surface of the substrate is approximately 10 ms based on the calculation that the width of the contact area between the printing roller and the plane is 50 microns. This treatment changes the water contact angle of the substrate from about 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com