Method for improving oxygen desorption performance of double perovskite oxide

A double perovskite and oxide technology, applied in the direction of alkali metal oxides/hydroxides, chemical instruments and methods, cobalt compounds, etc., can solve the problems of not being able to improve the oxygen desorption performance to a greater extent, and achieve technological Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

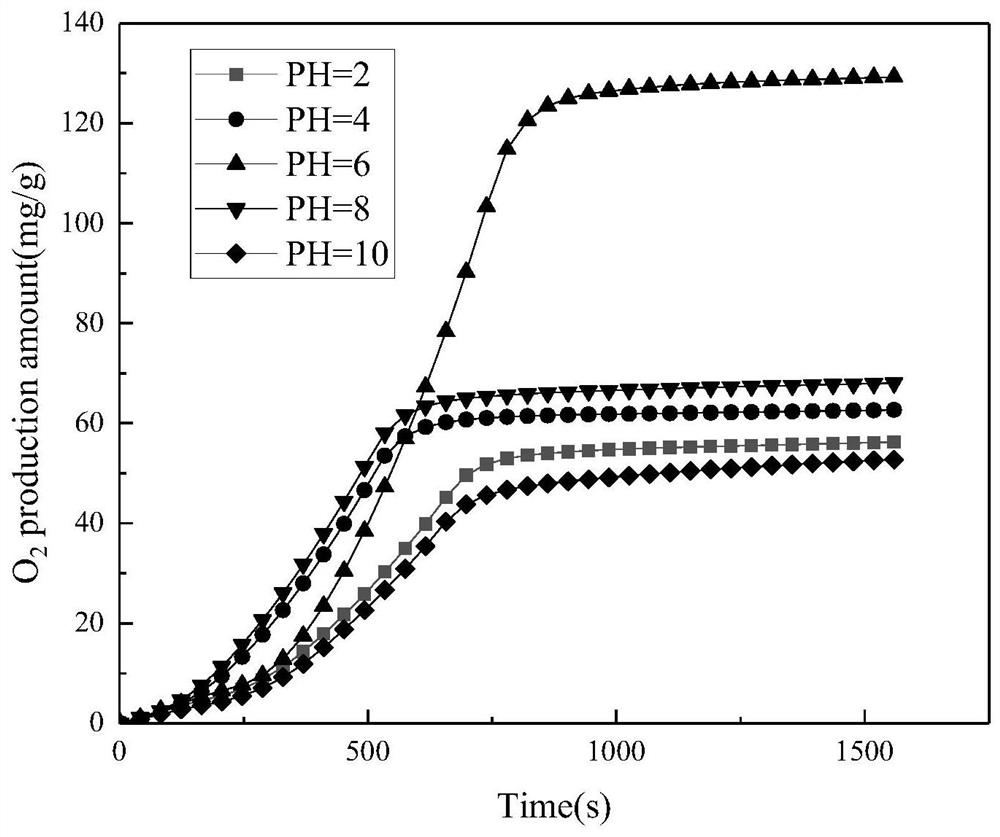

[0017] Example 1: PrBaCo at pH=2 2 o 6-δ Preparation of double perovskite oxygen carrier powder

[0018] Concrete preparation process is as follows:

[0019] (1) Weigh the analytically pure Pr(NO 3 ) 3 ·6H 2 O, Ba(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O. where Pr(NO 3 ) 3 ·6H 2 O is 0.02 mol. Add an appropriate amount of deionized water to make a metal nitrate aqueous solution; according to the total molar number of metal ions: citric acid: EDTA ratio of 1:1.5:1, weigh citric acid and EDTA and add it to the metal nitrate aqueous solution, add ammonia aqueous solution dropwise And slowly stir, measure the pH value of the solution to be 2, put it into a magnetic stirrer. Heat and stir at a constant temperature in a water bath magnetic stirrer at 80°C until uniform until a gel is formed;

[0020] (2) Put the above-mentioned stirred wet gel into a drying oven, and dry at 120° C. until a dry gel is formed;

[0021] (3) Take out the dry gel, grind it and put it into ...

Embodiment 2

[0024] Example 2: PrBaCo at pH=4 2 o 6-δ Preparation of double perovskite oxygen carrier powder

[0025] Concrete preparation process is as follows:

[0026] (1) Weigh the analytically pure Pr(NO 3 ) 3 ·6H 2 O, Ba(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O. where Pr(NO 3 ) 3 ·6H 2 O is 0.02 mol. Add an appropriate amount of deionized water to make a metal nitrate aqueous solution; according to the total molar number of metal ions: citric acid: EDTA ratio of 1:1.5:1, weigh citric acid and EDTA and add it to the metal nitrate aqueous solution, add ammonia aqueous solution dropwise And stir slowly, measure the pH value of the solution to be 4 and put it into a magnetic stirrer. Heat and stir at a constant temperature in a water bath magnetic stirrer at 80°C until uniform until a gel is formed;

[0027] (2) Put the above-mentioned stirred wet gel into a drying oven, and dry at 120° C. until a dry gel is formed;

[0028] (3) Take out the dry gel, grind it and put it in...

Embodiment 3

[0030] Example 3: PrBaCo at pH=6 2 o 6-δ Preparation of double perovskite oxygen carrier powder

[0031] Concrete preparation process is as follows:

[0032] (1) Weigh the analytically pure Pr(NO 3 ) 3 ·6H 2 O, Ba(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O. where Pr(NO 3 ) 3 ·6H 2 O is 0.02 mol. Add an appropriate amount of deionized water to make a metal nitrate aqueous solution; according to the total molar number of metal ions: citric acid: EDTA ratio of 1:1.5:1, weigh citric acid and EDTA and add it to the metal nitrate aqueous solution, add ammonia aqueous solution dropwise And slowly stir, put into the magnetic stirrer after measuring the pH value of the solution to be 6. Heat and stir at a constant temperature in a water bath magnetic stirrer at 80°C until uniform until a gel is formed;

[0033] (2) Put the above-mentioned stirred wet gel into a drying oven, and dry at 120° C. until a dry gel is formed;

[0034] (3) Take out the dry gel, grind it and put it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com