Device and method for large-scale continuous preparation of vertically oriented graphene by plasma

A vertical orientation and plasma technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., to achieve the effect of expanding the area, improving the preparation efficiency, and reducing the use of toxic and corrosive reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Continuous growth of large-area vertically oriented graphene using methane as hydrocarbon gas:

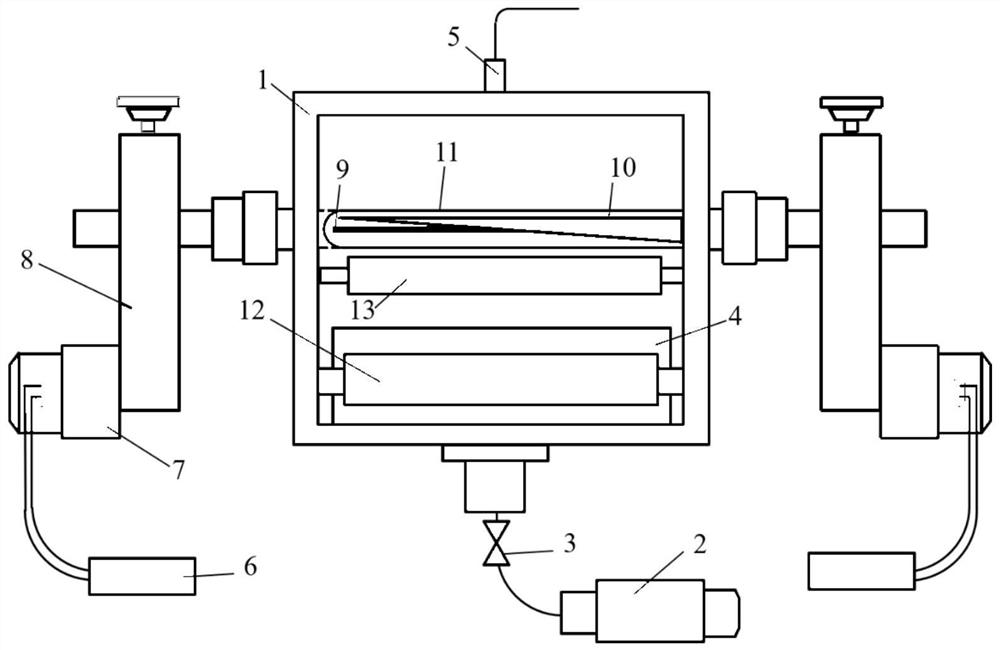

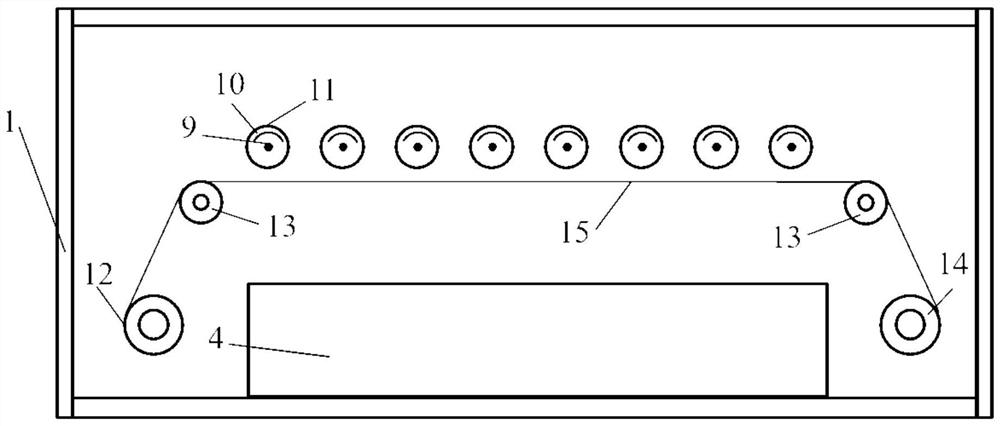

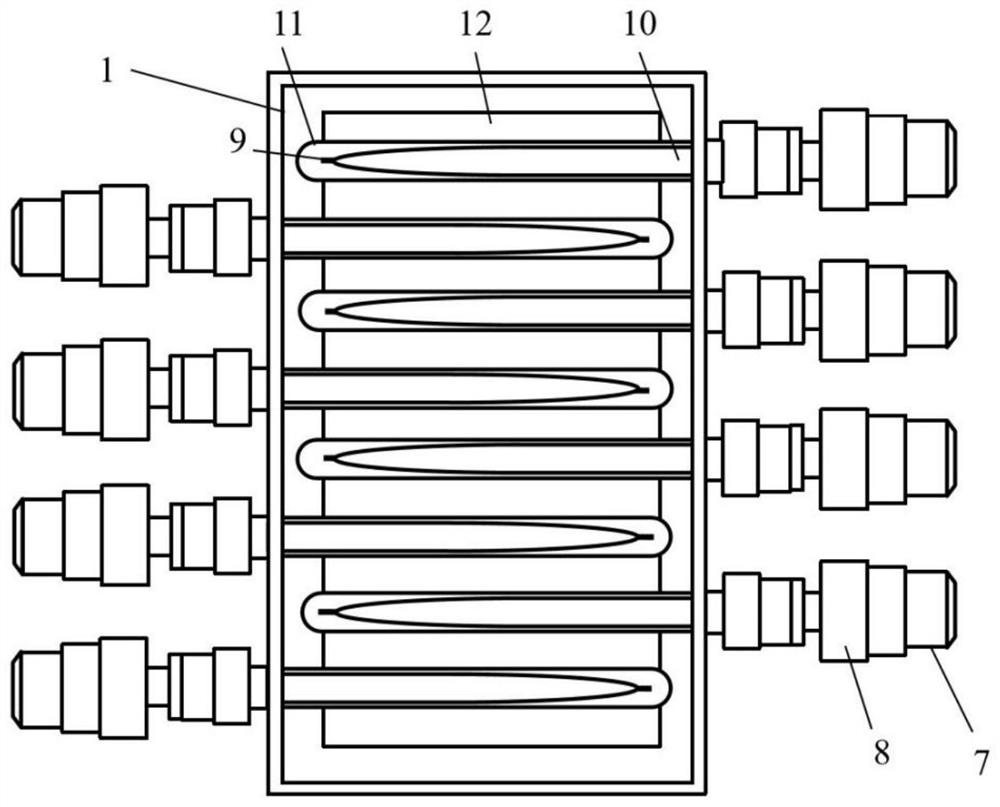

[0057] The plasma vertically aligned graphene preparation device used in this embodiment is as follows: figure 1 , figure 2 and image 3 mentioned. Wherein, the outer diameter of the quartz tube 11 is 30mm, and the wall thickness is 2mm. Among them, there are 4 antennas 9 (linear microwave antennas) that are turned on, and the maximum total power of the microwave power supply 6 is 1 kW, which supplies power for each linear microwave antenna 9 separately.

[0058] 1) Select a nickel foil with a thickness of 20 μm and a width of 20 cm as the base material, wind the nickel foil on the feed roller 12, and fix its rear end around the support roller 13 on the receiving roller 14. Adjust the shaft height of the support roller 13 so that the surface of the nickel foil is 0.7 cm away from the bottom of the quartz tube 11. Turn on the vacuum pump 2, and evacuate until the air pr...

Embodiment 2

[0066] The plasma vertically aligned graphene preparation device used in this embodiment is as follows: figure 1 , figure 2 and image 3 mentioned. Wherein, the outer diameter of the quartz tube 11 is 30mm, and the wall thickness is 2mm. Among them, there are four linear microwave antennas 9 that are turned on, and the maximum total power of the microwave power supply 6 is 1 kW, which supplies power for each linear microwave antenna 9 separately.

[0067]1) Select a nickel foil with a thickness of 20 μm and a width of 20 cm as the base material, wrap the nickel foil on the feed roller 12, and fix its rear end around the support roller 13 on the receiving roller 14. Adjust the axis height of the support roller 13 so that the surface of the nickel foil is 0.7 cm away from the bottom of the quartz tube 11. Turn on the vacuum pump 2, and evacuate until the air pressure inside the vacuum chamber 1 is 2.5Pa;

[0068] 2) Introduce hydrogen gas with a flow rate of 100ml / min into...

Embodiment 3

[0074] The plasma vertically aligned graphene preparation device used in this embodiment is as follows: figure 1 , figure 2 and image 3 mentioned. The outer diameter of the quartz tube 11 is 30 mm, and the wall thickness is 2 mm. Among them, there are 8 linear microwave antennas 9 that are turned on, and the maximum total power of the microwave power supply 6 is 1 kW, which supplies power for each microwave antenna 9 separately.

[0075] 1) Select a nickel foil with a thickness of 20 μm and a width of 20 cm as the base material, wind the nickel foil on the feed roller 12, and fix its rear end around the support roller 13 on the receiving roller. Adjust the shaft height of the support roller 13 so that the surface of the nickel foil is 0.7 cm away from the bottom of the quartz tube 11. Turn on the vacuum pump and evacuate until the air pressure inside the vacuum chamber 1 is 2.5Pa;

[0076] 2) Introduce hydrogen gas with a flow rate of 100ml / min into the vacuum chamber 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com