A kind of preparation method of boron carbide nanowire

A technology of nanowires and boron carbide, which is applied in the field of preparation of boron carbide nanowires, can solve the problems of low aspect ratio and uneven shape of C nanowires, and achieve the effects of uniform shape, low production cost, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

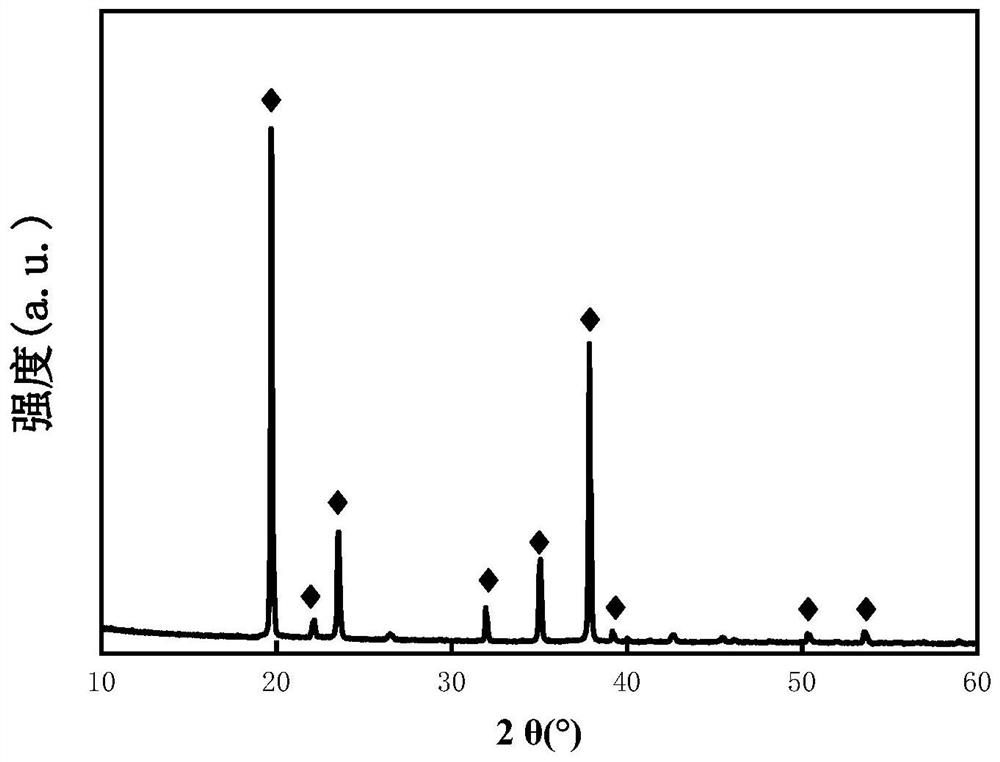

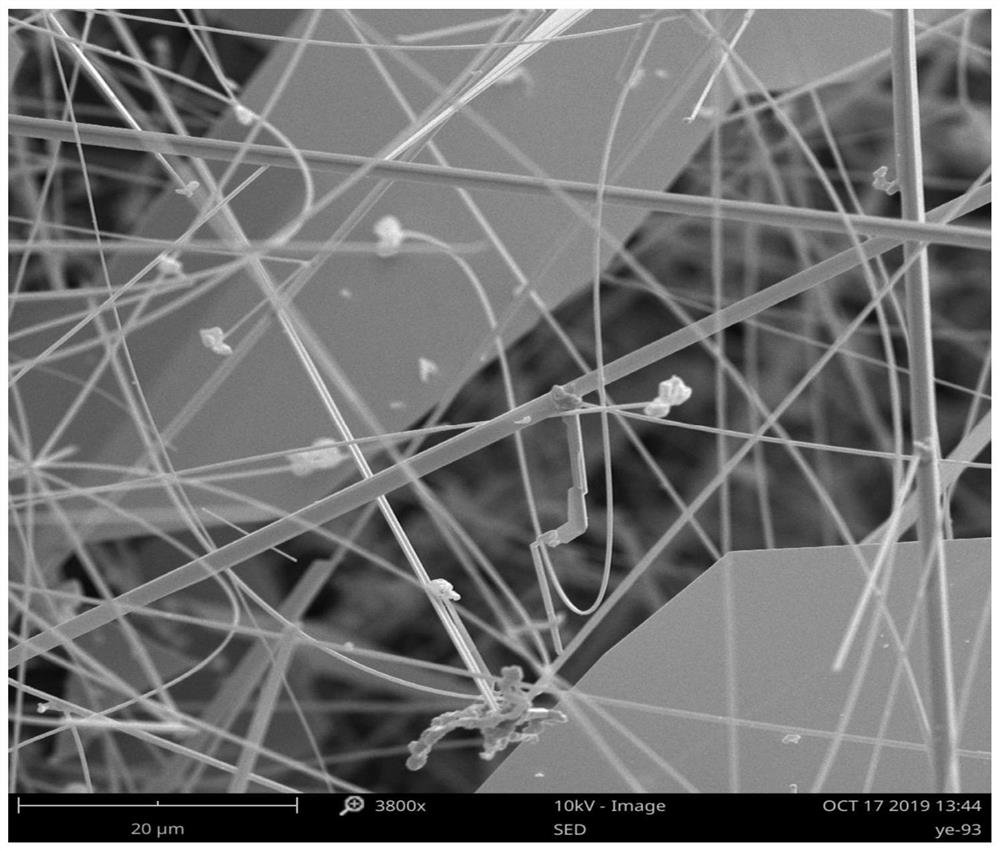

[0026] Specific implementation mode one: a kind of preparation method of boron carbide nanowire in this implementation mode, concretely carry out according to the following steps:

[0027] 1. Dry the boron oxide and boron powder, and mix them evenly to obtain a mixed powder;

[0028] 2. Put the mixed powder obtained in step 1 into the crucible, and heat it in a high-temperature furnace under the condition of an inert atmosphere. Stop feeding the inert gas, and feed the reducing gas to carry out the gas phase reaction to obtain the boron carbide nanowire, and complete the method.

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molar ratio of boron oxide and boron powder in Step 1 is (1-10):1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the drying temperature in step 1 is 50° C. to 150° C., and it is dried to a constant weight. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com