Doped positive electrode material precursor and preparation method and application thereof, doped positive electrode material and preparation method and application thereof

A positive electrode material and doping technology, applied in chemical instruments and methods, battery electrodes, inorganic chemistry, etc., can solve the problems of low particle strength and failure to meet actual needs, and achieve low process cost, high reliability of results, and realization of low difficulty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The first aspect of the present invention provides a method for preparing a doped cathode material precursor, characterized in that the method comprises the following steps:

[0048] (1) nickel salt, cobalt salt, and manganese salt are configured as a mixed salt solution; precipitant, complexing agent, and doping elements are respectively configured as a solution;

[0049] (2) In an inert atmosphere, add the mixed salt solution, precipitating agent solution, and complexing agent solution obtained in step (1) into the reactor, and start the co-precipitation reaction;

[0050] (3) At different stages of the co-precipitation reaction process described in step (2), the doping element solution is added in the reactor for n times, and the co-precipitation reaction is carried out to obtain the doped nickel-cobalt-manganese hydroxide, 2≤n≤5;

[0051] (4) Washing and drying the doped nickel-cobalt-manganese hydroxide obtained in step (3) to obtain the doped cathode material pre...

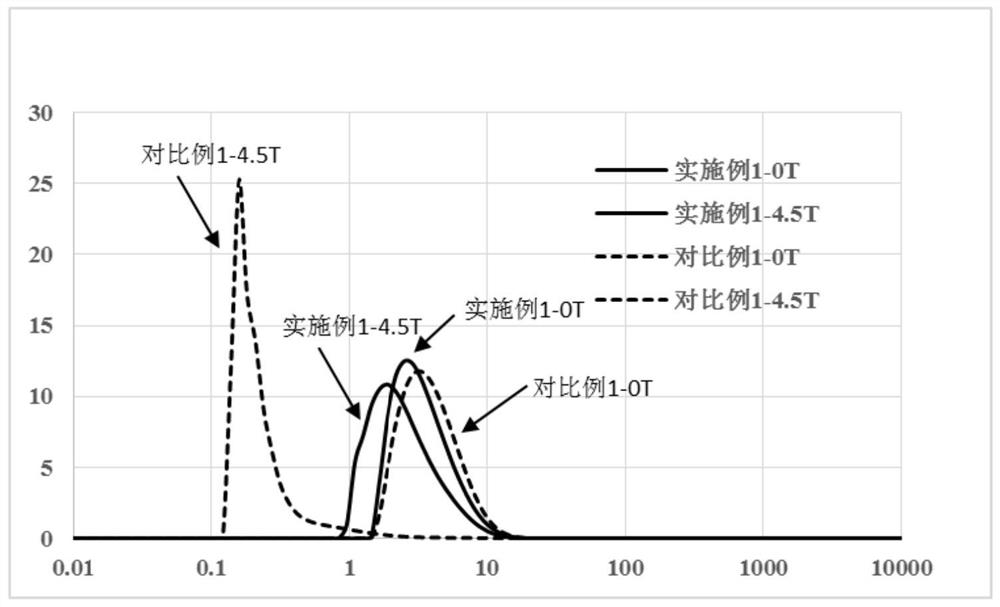

Embodiment 1

[0135] Prepare 1.5mol / L nickel-cobalt-manganese sulfate mixed solution (molar ratio Ni:Co:Mn=50:20:30), 3mol / L NaOH solution, 3mol / L ammonia water, and mix the above solutions in parallel The method was passed into the reaction kettle, the reaction temperature was kept at 50°C, and the reaction pH value was 11. Under the nitrogen protection atmosphere, the synthesis reaction was started, and the total reaction time was set at 200h. When the reaction was carried out to 60h, add 3g / L titanium sulfate (Ti(SO 4 ) 2 9H 2 (2) solution, carry out co-precipitation reaction; When reaction is carried out to 140h, add the 5g / L sodium metaaluminate (NaAlO 2 ) solution for co-precipitation reaction. After 200 hours of reaction, washing, drying at 120°C, and sieving, the desired doped multi-component nickel-cobalt-manganese hydroxide precursor Ni 0.496 co 0.197 mn 0.298 Ti 0.003 Al 0.002 (OH) 2 . Wherein, n=2, a2 is 3, and b2 is 7.

[0136] Take the above-mentioned doped nickel...

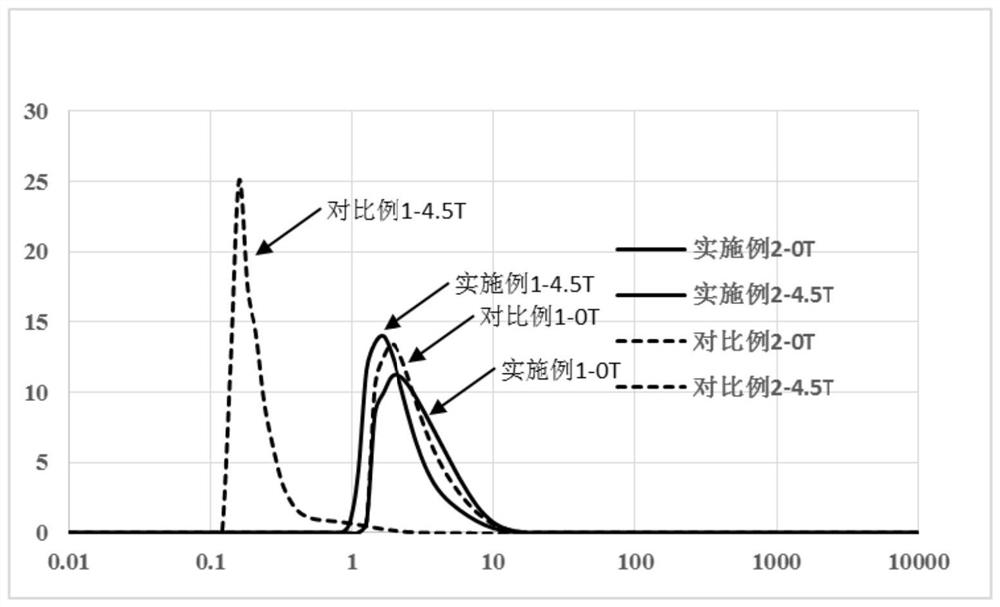

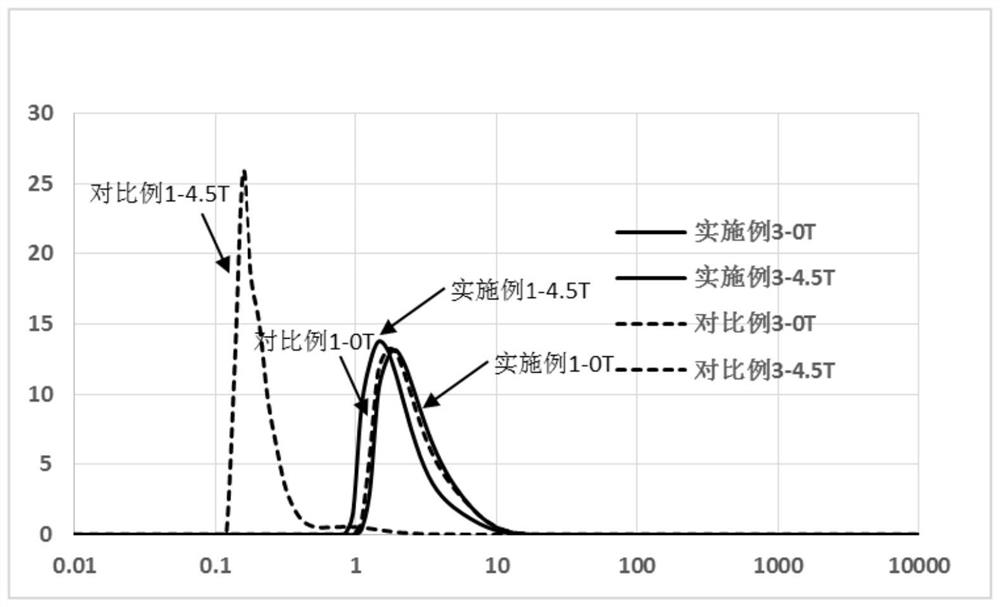

Embodiment 2

[0141] Prepare 1.8mol / L nickel-cobalt nitrate mixed solution (molar ratio Ni:Co:Mn=63:17:20), 5mol / L NaOH solution, 5mol / L ammonia water, and mix the above solutions in parallel The method is passed into the reaction kettle, the reaction temperature is kept at 55° C., and the reaction pH value is 11.5. Under the nitrogen protection atmosphere, the synthesis reaction is started, and the total reaction time is set at 180 h. When the reaction was carried out to 36h, add 4g / L zirconium sulfate (Zr(SO 4 ) 2 4H 2 (0) solution, carry out co-precipitation reaction; When reaction is carried out to 72h, add the 10g / L strontium nitrate (Sr(NO 3 ) 2 ) solution, carry out co-precipitation reaction; when the reaction is carried out to 135h, add the 12g / L barium nitrate (Ba(NO 3 ) 2 ) solution for co-precipitation reaction. After 180 hours of reaction, washing, drying at 120°C, and sieving, the desired doped multi-component nickel-cobalt-manganese hydroxide precursor Ni 0.622 co 0.16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com