Landfill Leachate Treatment System

A landfill leachate and treatment system technology, which is applied in the field of landfill leachate treatment systems, can solve problems such as large chroma, difficulty in achieving standard discharge with advanced oxidation technology, and complex pollutant components, so as to achieve good treatment effect and reduce one-time investment , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

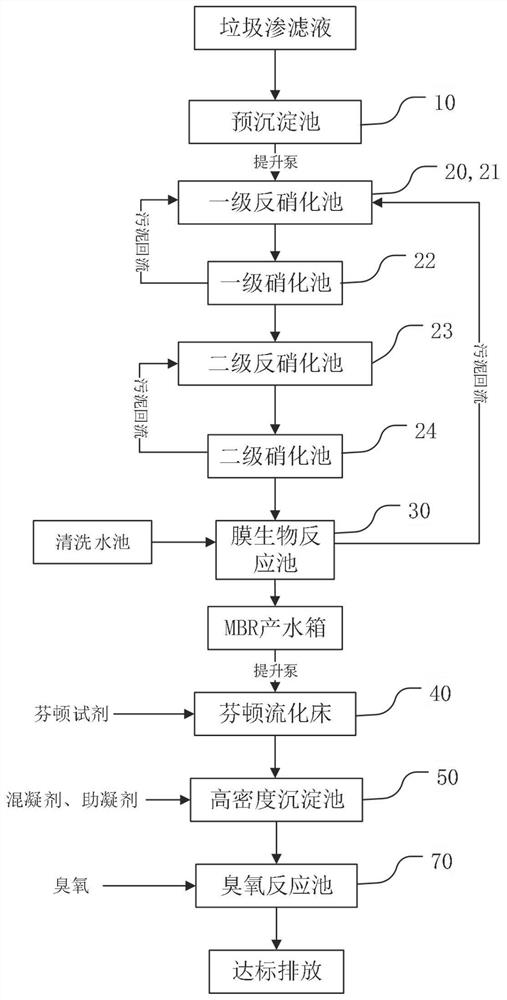

[0059] In a specific embodiment, the design treatment water volume is 200m 3 / d, influent COD50000-60000 mg / L, total nitrogen 2000-3000 mg / L, ammonia nitrogen 1500-2000 mg / L, effluent implements "Standards for Pollution Control of Domestic Garbage Landfill Sites", requiring COD 100mg / L, ammonia nitrogen 25 mg / L, total nitrogen 40 mg / L. The specific implementation is as follows:

[0060] The generated landfill leachate flows to the pre-sedimentation tank by itself, and the design capacity of the pre-settling tank is 20,000m 3 , the residence time is more than 3 months, and the effluent from the pre-sedimentation tank is pumped into the double-stage nitrification-denitrification system. The nitrification tank and the denitrification tank are equipped with a submersible mixer, and the nitrification tank is equipped with an automatic sodium acetate dosing device, and a nitrate nitrogen monitor is installed at the inlet and outlet respectively. According to the total nitrogen rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com