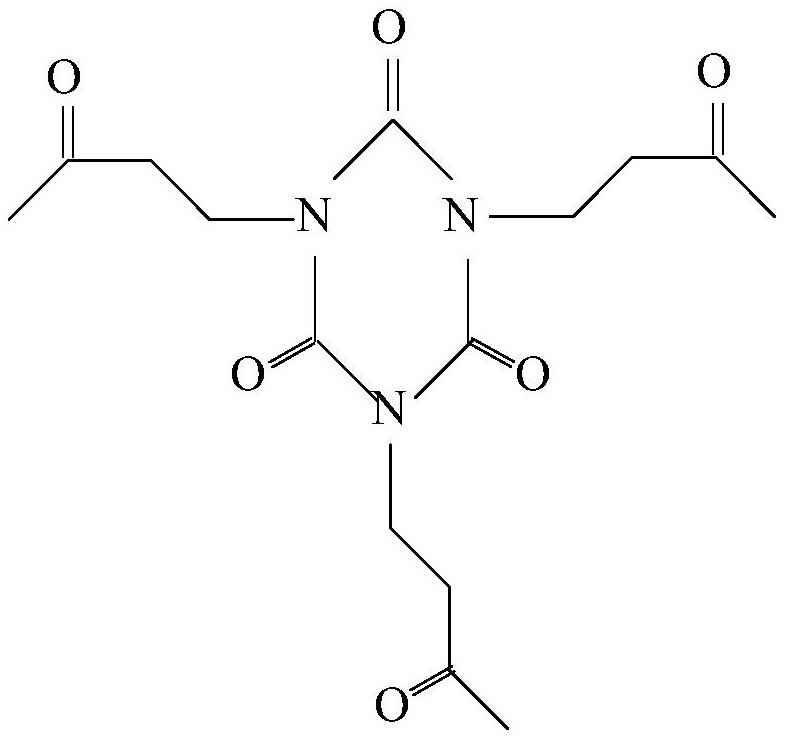

Preparation method of curing agent intermediate N, N, N-tri(3'-methyl propionate)-1, 3, 5-triazine

A technology of methyl propionate and methyl acrylate, which is applied in the field of preparation of curing agent intermediate N,N,N-tri-1,3,5-triazine, which achieves low environmental pollution, simple separation and purification process, and high product quality The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

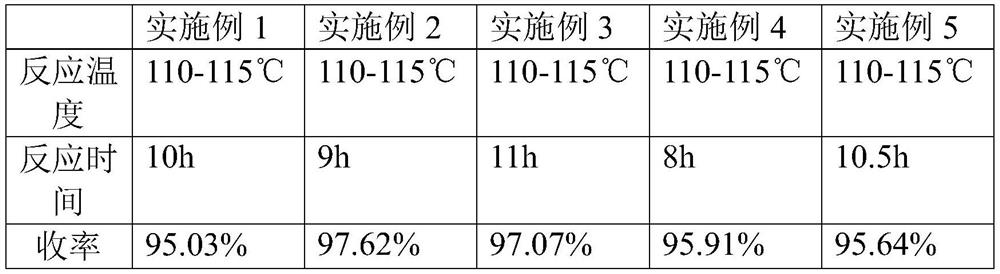

Embodiment 1

[0016] In a 500mL four-neck flask equipped with a thermometer and a condenser tube, add 30g of xylene, 12.9g of cyanuric acid, 25.9g of methyl acrylate, 0.4g of tetrabutylammonium bromide, and 0.2g of hydroquinone, and heat up When the temperature reaches 110-115°C, the reaction time is 10h (monitor the reaction with liquid chromatography). After the reaction, the temperature of the organic phase was lowered to 5-8°C, the crystallization was complete, and it was filtered to obtain the N,N,N-tris(3'-propionic acid methyl)-1,3,5-triazine product. The rate is 95.03%.

Embodiment 2

[0018] In a 500mL four-necked flask equipped with a thermometer and a condenser tube, add 30g of toluene, 12.9g of cyanuric acid, 34.4g of methyl acrylate, 5.0g of tetraisopropylammonium bromide, and 3.0g of hydroquinone, and heat up When the temperature reaches 110-115°C, the reaction time is 9h (monitor the reaction by liquid chromatography). After the reaction, the temperature of the organic phase was lowered to 5-8°C, the crystallization was complete, and it was filtered to obtain the N,N,N-tris(3'-propionic acid methyl)-1,3,5-triazine product. The rate is 97.62%.

Embodiment 3

[0020] In a 500mL four-necked flask equipped with a thermometer and a condenser, add 50g of toluene, 12.9g of cyanuric acid, 31.0g of methyl acrylate, 1.5g of tetrabutylammonium bromide, and 1.0g of hydroquinone, and heat up to At 110-115°C, the reaction time is 11h (monitor the reaction by liquid chromatography). After the reaction, the temperature of the organic phase was lowered to 5-8°C, the crystallization was complete, and it was filtered to obtain the N,N,N-tris(3'-propionic acid methyl)-1,3,5-triazine product. The rate is 97.07%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com