Machining method of GH4169 disc and shaft integrated forged piece

A technology of GH4169 and processing method, applied in the field of alloy forging, can solve the problems such as forgings with complex shapes that cannot be used for forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

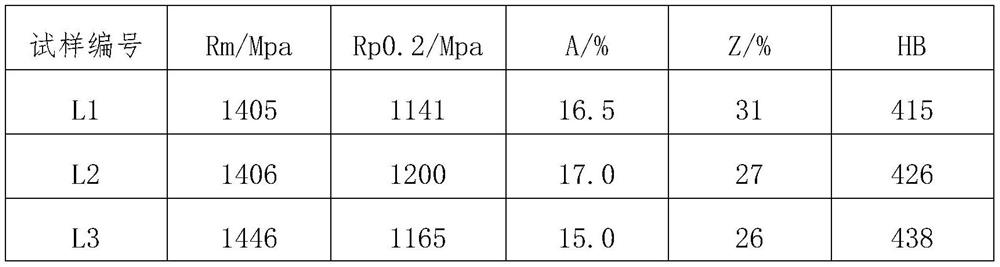

Examples

Embodiment 1

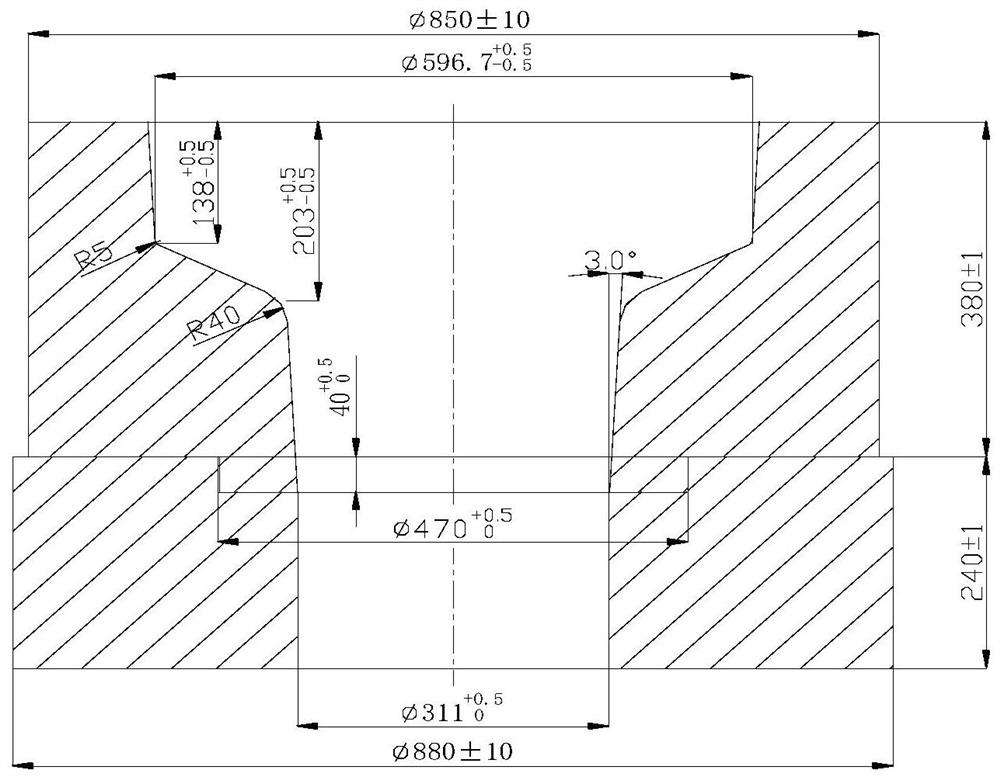

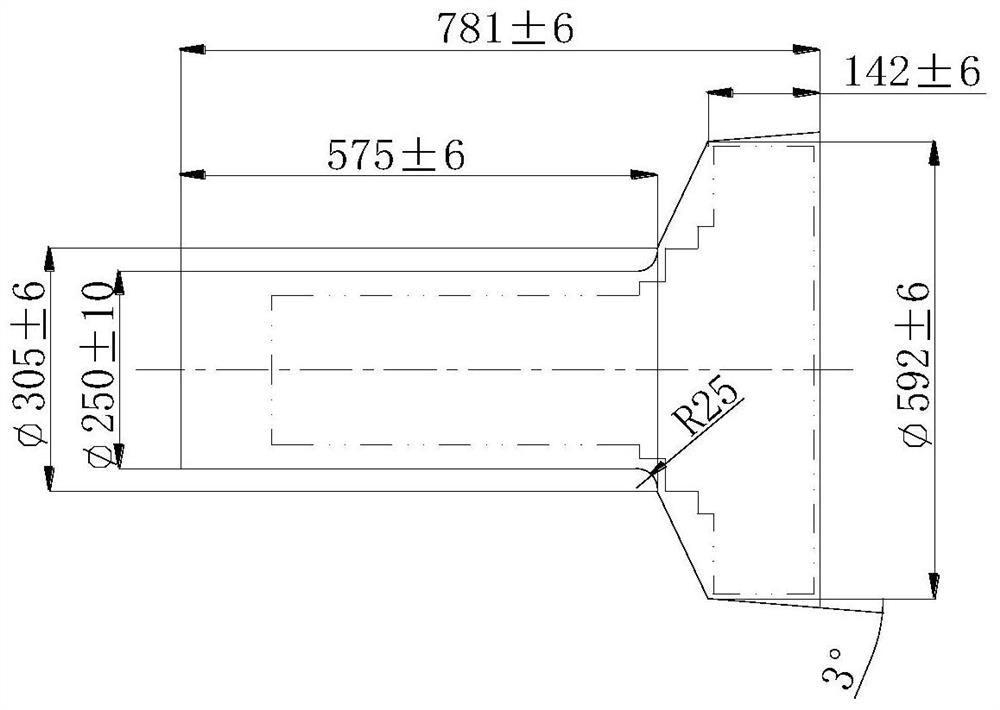

[0023] A processing method for a GH4169 disc-shaft integrated forging, the specific method is as follows:

[0024] 1. Blanking: The raw material of GH4169 alloy bar is blanked according to the corresponding specifications to obtain the blank before forging.

[0025] 2. Machining flat end face: For the blanked GH4169 alloy bar, the two end faces of the blanked GH4169 alloy bar are exposed to the minimum amount, and the tolerance of flatness and verticality after the end face is ±0.5mm.

[0026] 3. One-time heating: Round both ends of the billet to R20mm, and wrap asbestos with a thickness of 60mm on any end of the billet. The length of the billet wrapped is 380mm. Heat it to 850°C for heat preservation, and then heat to 1040°C for heat preservation.

[0027] Further, for the heat preservation, the heat preservation time is calculated by the effective thickness of the blank × 0.6 min.

[0028] 4. Combined forging:

[0029] a. Tire mold forging: After preheating the tire mold, ...

Embodiment 2

[0034] A processing method for a GH4169 disc-shaft integrated forging, the specific method is as follows:

[0035] 1. Blanking: The raw material of GH4169 alloy bar is blanked according to the corresponding specifications to obtain the blank before forging.

[0036] 2. Machining flat end face: For the blanked GH4169 alloy bar, the two end faces of the blanked GH4169 alloy bar are exposed to the minimum amount, and the tolerance of flatness and verticality after the end face is ±0.5mm.

[0037] 3. One-time heating: Round both ends of the billet to R25mm, and wrap asbestos with a thickness of 70mm at any end of the billet. The length of the billet wrapped is 385mm. Heat it to 850°C for heat preservation, and then heat to 1040°C for heat preservation.

[0038] Further, for the heat preservation, the heat preservation time is calculated by the effective thickness of the blank × 0.6 min.

[0039] 4. Combined forging:

[0040] a. Tire mold forging: After preheating the tire mold, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com