Environment-friendly process for producing lithium carbonate by mixing spodumene and lithium polymer

A technology of lithium polymer and spodumene, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problem of low utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

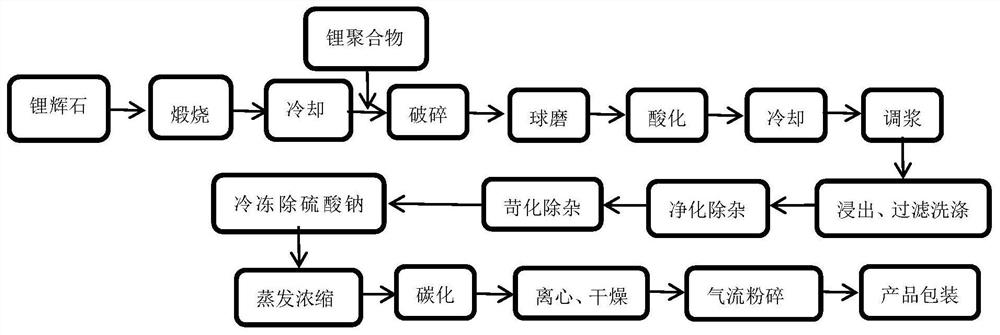

[0057] like figure 1 and figure 2 Shown, a kind of environment-friendly type mixes the technique for producing lithium carbonate with spodumene and lithium polymer, comprises the following steps:

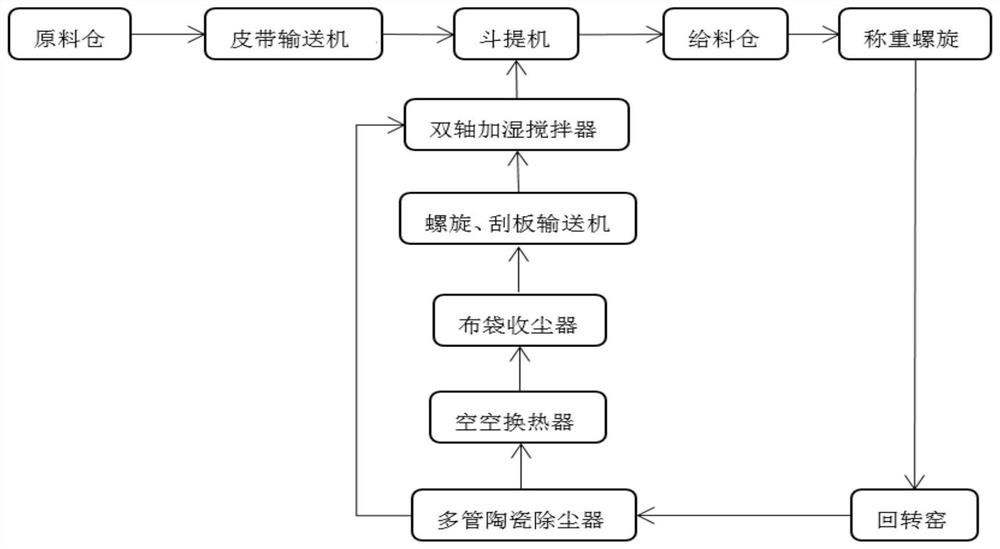

[0058] S1. Transform the spodumene through rotary kiln calcination, the calcination temperature is 950-1200°C, the smoke generated during the calcination process is passed through the tail gas treatment system, and the dust is recovered to the double-shaft humidification mixer for humidification treatment, and the secondary calcination is carried out again to obtain Spodumene baking material: mix spodumene baking material and lithium polymer according to a certain weight ratio, lithium polymer: spodumene baking material = 1 ~ 3:1, and then undergo calcination, cooling, fine grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com