Environment-friendly process for producing lithium hydroxide monohydrate by mixing spodumene and salt lake ore

A technology of lithium hydroxide monohydrate and lithium hydroxide, which is applied in the direction of lithium oxide;/hydroxide, mixer, mixer with rotating stirring device, etc., can solve the problem of low utilization rate of raw materials and achieve increased resistance Insufficient resources, improving uniformity, and reducing the effect of calcium ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing, but protection scope of the present invention is not limited to the following description.

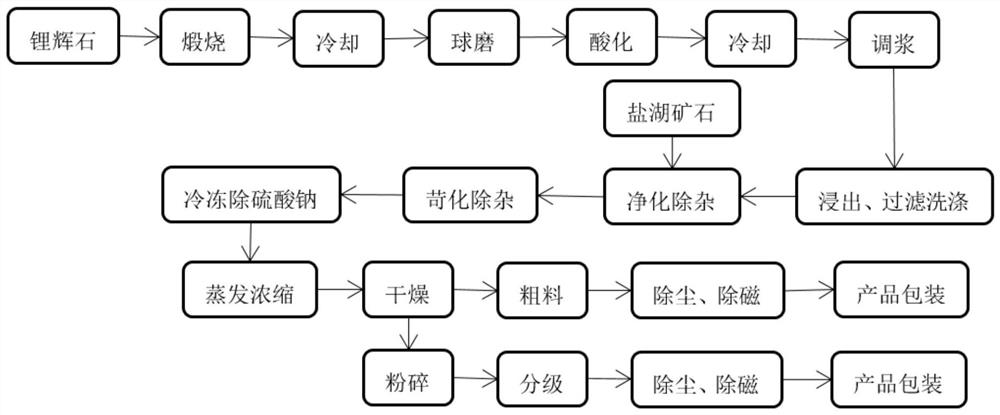

[0056] Such as figure 1 with figure 2 Shown, a kind of environment-friendly type mixes the technique for producing lithium hydroxide monohydrate with spodumene and salt lake ore, comprises the following steps:

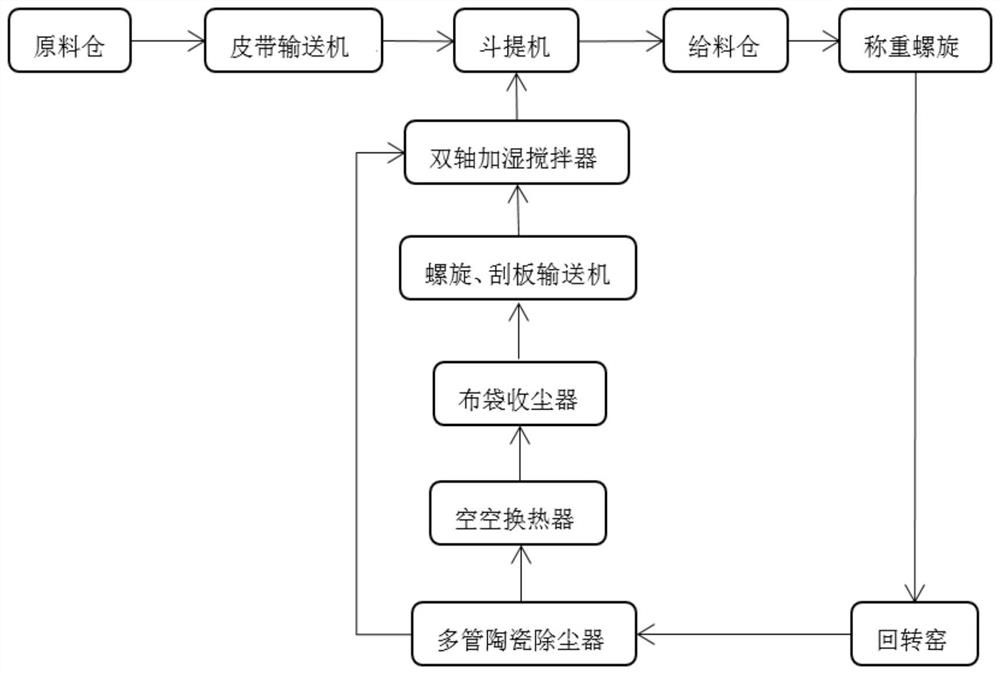

[0057] S1. Transform the spodumene through calcination. The calcination process is carried out in the rotary kiln. The smoke generated by the rotary kiln passes through the tail gas treatment system, and the dust is recycled to the biaxial humidification mixer for humidification treatment, and then calcined again, and then sequentially cooled, Fine grinding, acid reaction, cooling, after the acid reaction product is cooled to ≤90°C, it is made into a slurry with water, and the solid content of the slurry is 10% to 70%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com