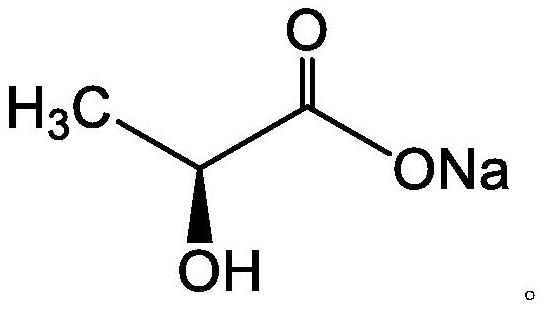

Industrial preparation method of sodium lactate solution

A technology of sodium lactate solution and lactic acid solution, which is applied in carboxylate preparation, carboxylate preparation, organic chemical methods, etc., and can solve the problems of sodium lactate loss, unfavorable industrial production, and increased decolorization operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

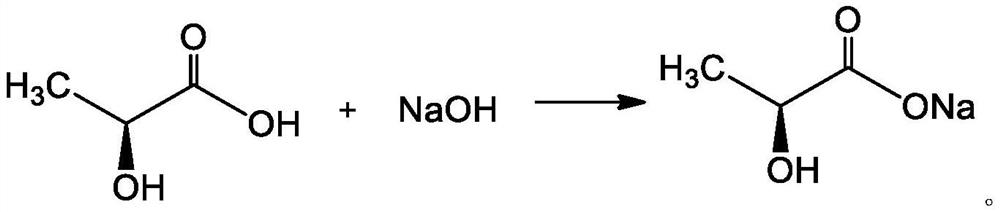

Method used

Image

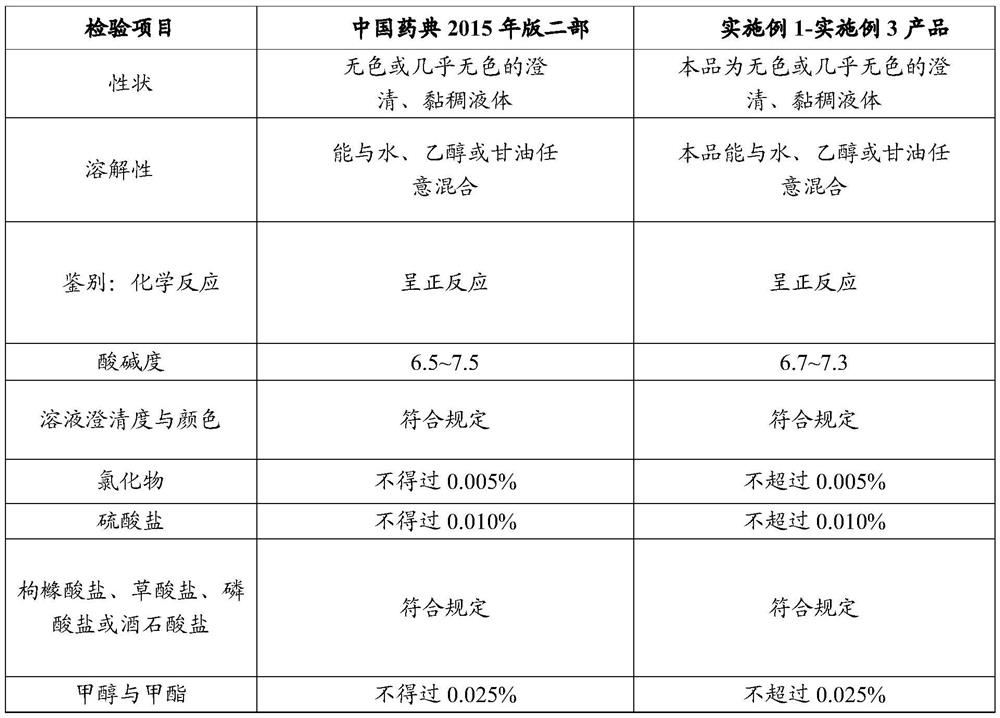

Examples

Embodiment 1

[0033] This embodiment provides a preparation method of sodium lactate solution. Batch is 2500kg / batch, concentration is the sodium lactate solution of 40%, its industrial production preparation method, comprises the steps:

[0034] Pump 1000kg of lactic acid solution with a concentration of 82% into a 3000L sodium lactate synthetic enamel reaction kettle; add 1200kg of purified water to another 2000L enamel reaction kettle, and add 380kg of sodium hydroxide into the reaction kettle under stirring and cooling , when the temperature of the sodium hydroxide solution drops to 50°C, the sodium hydroxide solution is pumped into the high position of the sodium lactate synthesis enamel reaction kettle through the material pump.

[0035] Turn on the sodium lactate synthesis enamel reaction kettle to stir. At this time, the temperature of the feed liquid in the reactor is 22°C. Fast, when the sodium hydroxide solution is added dropwise to about 2 / 3, the temperature of the feed liquid ...

Embodiment 2

[0039] Batch is 2500kg / batch in the present embodiment, and concentration is the industrialized production preparation method of the sodium lactate solution of 40%, comprises the steps:

[0040]Pump 1000kg of lactic acid solution with a concentration of 82% into a 3000L sodium lactate synthetic enamel reaction kettle; add 1200kg of purified water to another 2000L enamel reaction kettle, and add 380kg of sodium hydroxide into the reaction kettle under stirring and cooling , when the temperature of the sodium hydroxide solution drops to 40°C, pump the sodium hydroxide solution into the high position of the sodium lactate synthesis enamel reaction kettle through the material pump.

[0041] Turn on the sodium lactate synthesis enamel reaction kettle to stir. At this time, the temperature of the feed liquid in the reactor is 20.5°C. Fast, when the sodium hydroxide solution is added dropwise to about 2 / 3, the temperature of the feed liquid in the reactor tends to be stable), and whe...

Embodiment 3

[0045] In the present embodiment, the batch is 2500kg / batch, and the concentration is the industrial production preparation method of the sodium lactate solution of 40%, the steps are as follows:

[0046] Pump 1000kg of lactic acid solution with a concentration of 82% into a 3000L sodium lactate synthetic enamel reaction kettle; add 1200kg of purified water to another 2000L enamel reaction kettle, and add 380kg of sodium hydroxide into the reaction kettle under stirring and cooling , when the temperature of the sodium hydroxide solution drops to 30°C, pump the sodium hydroxide solution into the high position of the sodium lactate synthesis enamel reaction kettle through the material pump.

[0047] Turn on the sodium lactate synthesis enamel reaction kettle and stir. At this time, the temperature of the feed liquid in the reactor is at 21°C. Control the temperature of the feed liquid in the reactor within 35°C and slowly add sodium hydroxide solution (the temperature of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com