Porous polyolefin film and preparation method thereof

A polyolefin and composite polyolefin technology, which is applied in the field of porous membranes and can solve problems such as large pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of porous polyolefin film provided by the invention comprises the following steps:

[0029] S1. Mix the water-soluble organic porogen and the inorganic porogen in a mass ratio (40%:60%)~(60%:40%) to obtain a multi-level composite porogen. The organic porogen is in The viscosity at 200°C is 300-3000 centipoise; the water-soluble organic porogen and the inorganic porogen are first mixed, and the water-soluble organic porogen is coated on the surface of the inorganic porogen, and the water-soluble organic porogen can also be Acting as a dispersion modifier for inorganic porogens and polyolefins, it can improve the dispersibility of subsequent mixing with polyolefins.

[0030] S2. Melt, blend and extrude the multi-stage composite porogenic material obtained in step S1 and polyolefin in a twin-screw extruder at a mass ratio of 2%: 98% to 30%: 70%, and shape it to obtain a composite polyolefin. Olefin flakes;

[0031] S3. Perform biaxial stretch...

Embodiment 1

[0043] A kind of preparation method of porous polyolefin film, comprises the following steps:

[0044] S1. the molecular weight is 5000g / mol, the viscosity is the polyethylene glycol of 300 centipoise (200 ℃) and calcium carbonate (2500 order) by mass ratio 50%: 50% dry, mix uniformly, obtain multistage composite porogenic material; The water-soluble polyethylene glycol and calcium carbonate are mixed first, and the polyethylene glycol is coated on the surface of the calcium carbonate, so as to improve the dispersibility when subsequently mixed with polyolefin.

[0045] S2. The multi-stage composite porogenic material obtained in step S1 and polyethylene are melt-blended and extruded in a twin-screw extruder at a mass ratio of 15%:85% (the temperature of melt-blending is 160° C.), flow Casting (the temperature of tape casting is 245°C, and the casting speed is 10m / min) to obtain composite polyethylene sheets;

[0046] S3. Perform biaxial stretching treatment on the composite ...

Embodiment 2-5

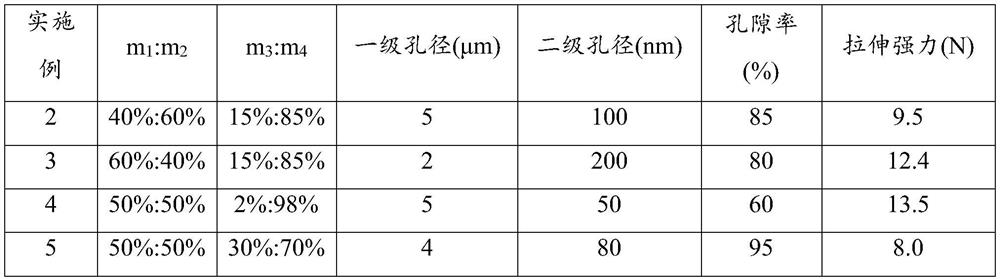

[0049] A kind of preparation method of porous polyolefin film, compared with embodiment 1, difference is, in steps S1 and S2, the mass ratio m of polyethylene glycol and calcium carbonate 1 :m 2 and the mass ratio of multi-level composite porogenic material to polyethylene m 3 :m 4 As shown in Table 1, the others are roughly the same as those in Embodiment 1, and will not be repeated here.

[0050] Preparation conditions and performance test results of table 1 embodiment 2-5

[0051]

[0052] It can be seen from Table 1 that with the increase of porogenic material content, the porosity of the porous membrane material increases, and the tensile strength of the membrane material decreases. In addition, with the increase of the organic porogen in the composite porogenic material, the secondary microporous structure of the porous membrane also increases correspondingly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com