ABS alloy material capable of releasing negative oxygen ions as well as preparation method and application of ABS alloy material

A technology of negative oxygen ions and alloy materials, which is applied in the field of ABS alloy materials that can release negative oxygen ions and its preparation, can solve problems such as no solution, and achieve the effects of efficient release, huge market space, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

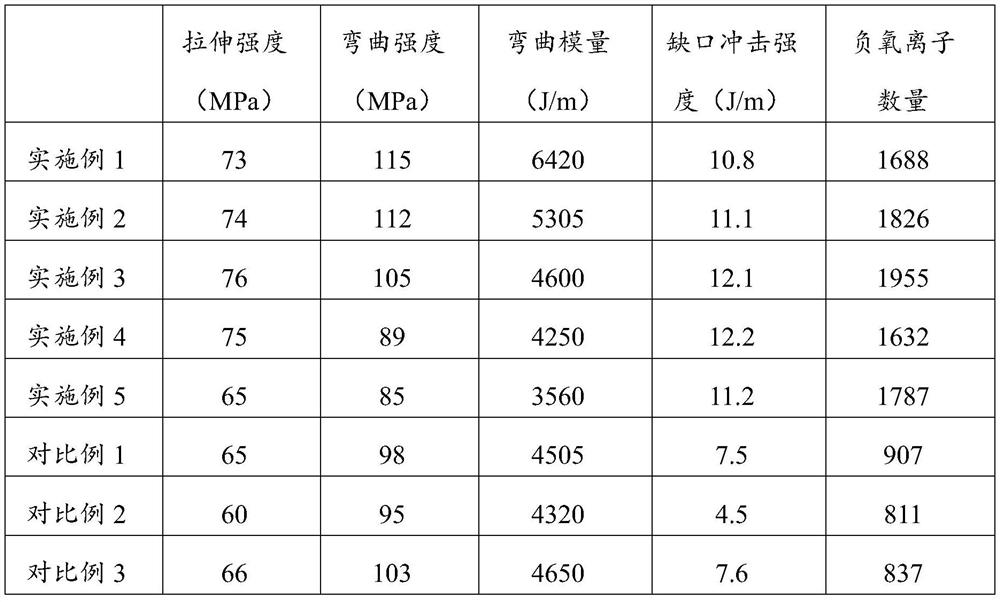

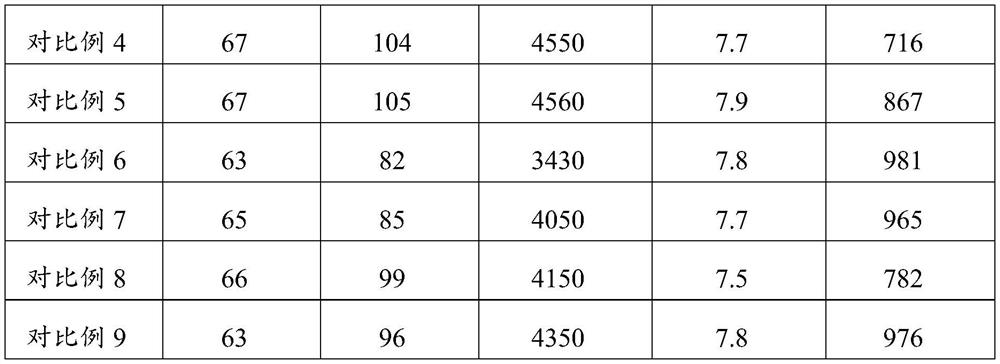

Examples

Embodiment 1

[0025] 67 parts of carrier resin, 30 parts of glass fiber, 0.5 part of compatibilizer, 2 parts of modified tourmaline powder, and 0.5 part of lubricant. The weight ratio of ABS resin and ASA resin in the carrier resin is 1:1.

[0026] Preparation:

[0027] Weigh ABS resin, ASA resin, and modified tourmaline powder in parts by weight and place them in a high-speed mixer to mix at 500-750r / min, and then mix at 50-150r / min to obtain a premix;

[0028] Put the premixed material in the main feeding port of the twin-screw extruder, then add compatibilizer and lubricant at the front section of the side feeding port and glass fiber at the side feeding port at the same time, and pass through the twin-screw extruder (dual The rotating speed of the screw extruder is 350-500r / min, and the temperature range of the extrusion zone is 180-260°C) and mix uniformly to obtain an ABS alloy material capable of releasing negative oxygen ions.

Embodiment 2

[0030] 68 parts of carrier resin, 26 parts of glass fiber, 1.5 parts of compatibilizer, 3 parts of modified tourmaline powder, and 1.5 parts of lubricant. The weight ratio of ABS resin and ASA resin in the carrier resin is 1.2:1.

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0033]70 parts of carrier resin, 22 parts of glass fiber, 2 parts of compatibilizer, 4 parts of modified tourmaline powder, and 2 parts of lubricant. The weight ratio of ABS resin and ASA resin in the carrier resin is 1.5:1.

[0034] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com